Porous membrane material for detecting phosphoinositide, and preparation and detection method thereof

A detection method and phosphoinositide technology, applied in the field of biological analysis, can solve the problems of difficulty in rapid detection, low detection sensitivity, complex biological system, etc., and achieve the effects of good scalability, high detection sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

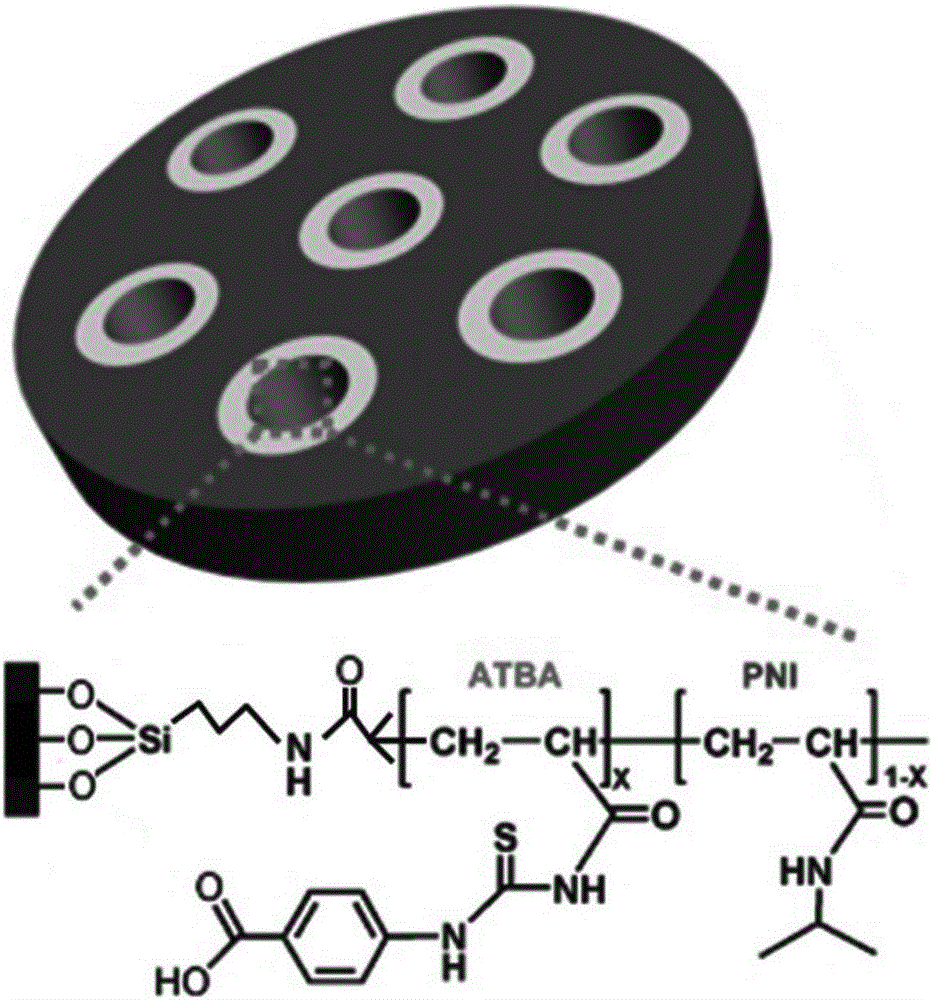

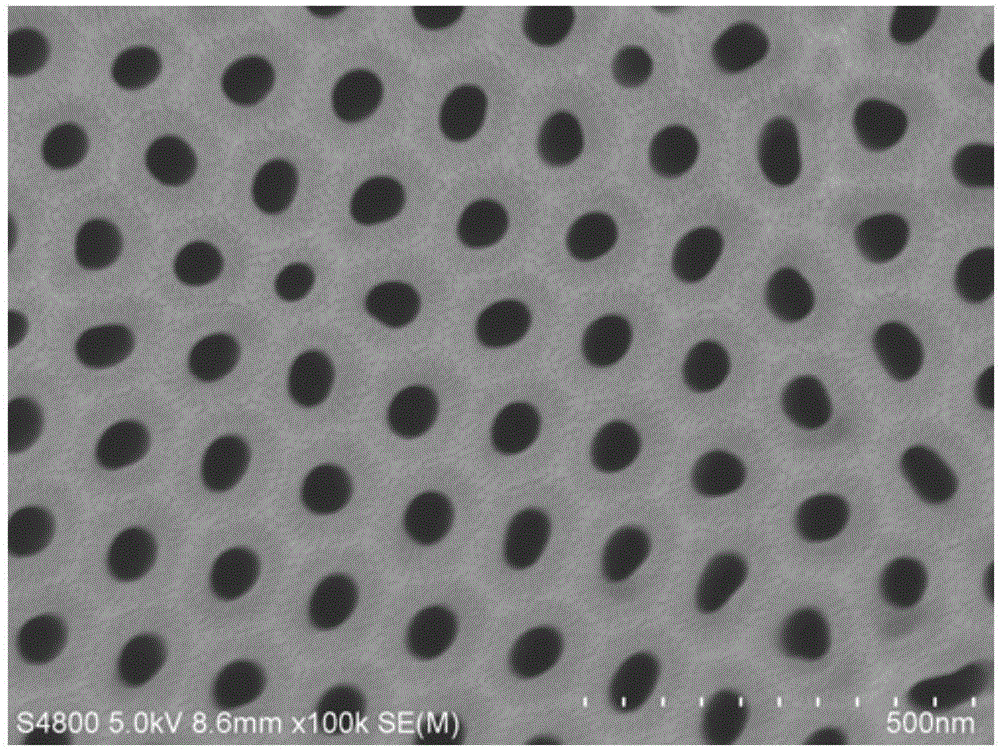

[0045] Preparation of Porous Membrane Material Grafted with Bicomponent Copolymer

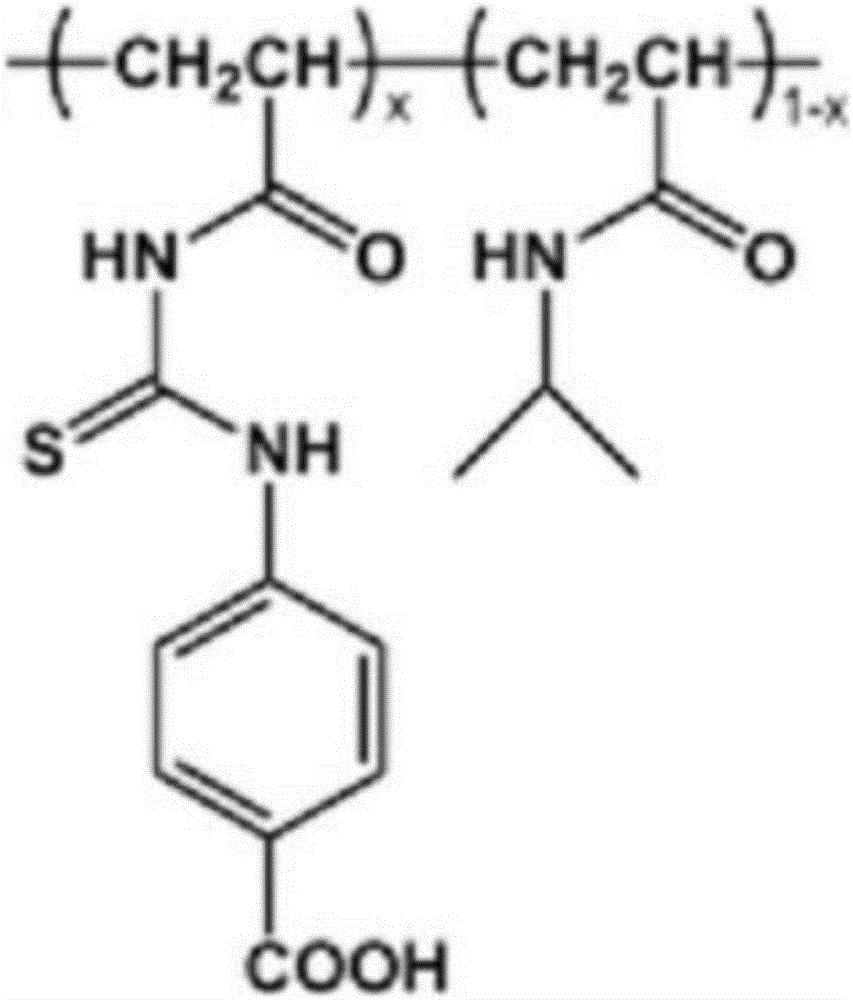

[0046] The structure of the two-component copolymer is as figure 1 Shown, where X = 0.01-0.5. Taking X=0.2 as an example, add 4.8mmol isopropylacrylamide (NIPAM) and 1.2mmol 4-(3-propenylthioureido)benzoic acid (ATBA) into a 100mL three-necked flask, and add 60mL N,N' - Dimethylformamide (DMF) sonicated for 10 minutes. After passing nitrogen gas for 20 minutes, add 32 mg cuprous bromide (CuBr) powder and mix well. The brominated porous membrane was added into the flask, and then the reaction system was evacuated and filled with nitrogen to remove residual oxygen in the reaction system. Then 0.16 mL of N,N,N',N',N'-pentamethyldiethylenetriamine (PMDETA) or bipyridyl ligand was added by injection, followed by one more deoxygenation treatment. Under nitrogen protection and a constant temperature of 70°C, take it out after 15 hours of reaction, soak and rinse with 100mL DMF and deionized water ...

Embodiment 2

[0050] The QCM-D adsorption method was used to evaluate the different adsorption behaviors of (1,3) inositol diphosphate, (1,3,5) inositol triphosphate and inositol hexaphosphate on the surface of the two-component copolymer. According to the similar method described in Example 1, the two-component copolymer was grafted onto the surface of the QCM-D chip. Under the condition of temperature control at 20°C, deionized water was used as the carrier liquid for the concentration of 1 μg / mL (1, 3) Inositol diphosphate, (1,3,5) inositol triphosphate and inositol hexaphosphate were subjected to adsorption experiments. Figure 5 It shows that the surface of the two-component copolymer has strong adsorption for (1,3) inositol diphosphate, (1,3,5) inositol triphosphate and inositol hexaphosphate and has a certain ability to distinguish, that is, three The adsorption amounts of different phosphoinositides on the surface of the two-component copolymers were different.

Embodiment 3

[0052] The film material obtained by grafting the two-component copolymer on the QCM-D chip prepared as described in Example 2 was soaked in 10 ml of an aqueous solution containing 10 mg of inositol hexaphosphate for 20 minutes. Then, the changes on the surface of the two-component copolymer film material before and after soaking inositol hexaphosphate were observed through the scanning mode of the atomic force microscope. Depend on Image 6 and Figure 7 It can be observed that the surface of the polymer film material has obvious morphological changes after soaking in the inositol hexaphosphate solution, indicating that the polymer film is responsive to inositol hexaphosphate, which can be amplified to the change of the macroscopic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com