A kind of preparation method of high temperature CO2 calcium-based adsorbent doped with silicon nitride

A calcium-based adsorbent and silicon nitride technology, which is applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of reduced effective content of CaO, decreased cycle adsorption performance, and reduced cycle adsorption performance. High efficiency, high adsorption performance, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

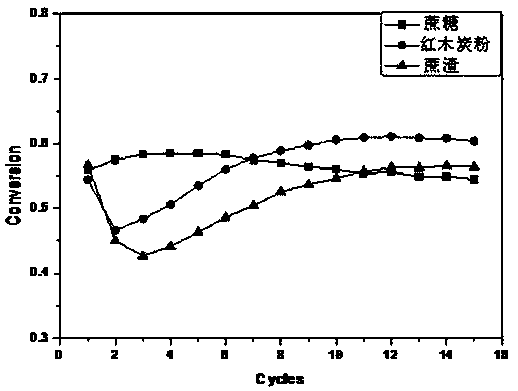

Embodiment 1

[0041] Embodiment 1: with calcium gluconate Ca (C 6 h 11 o 7 ) 2 As CaO precursor, doped with Si prepared from sucrose 3 N 4 Preparation of doped high temperature CO 2 Calcium based sorbent.

[0042] A high-temperature CO doped with silicon nitride 2 The preparation method of calcium-based adsorbent specifically comprises the following steps:

[0043] (1) Put wood powder sucrose in a vacuum tube furnace, and feed inert gas N with a flow rate of 150mL / h into the tube furnace 2 , at a temperature of 700°C, the inert gas N 2 Carbonization reaction in the atmosphere for 2h to obtain carbon powder;

[0044] (2) Mix the carbon powder and tetraethyl orthosilicate evenly in step (1), wherein the C:Si molar ratio of the carbon powder and tetraethyl orthosilicate is 1.5:1, and add it dropwise at a stirring speed of 500r / min Ammonia water (the solid-to-liquid ratio g:mL of carbon powder and ammonia water is 1:0.5, NH in ammonia water 4+ The concentration of the solution is 1.47 ...

Embodiment 2

[0049] Embodiment 2: calcium gluconate Ca (C 6 h 11 o 7 ) 2 It is a CaO precursor, doped with Si prepared from red charcoal powder 3 N 4 Preparation of calcium-based sorbent.

[0050] A high-temperature CO doped with silicon nitride 2 The preparation method of calcium-based adsorbent specifically comprises the following steps:

[0051] (1) Put the mahogany charcoal powder in a vacuum tube furnace, and feed an inert gas N with a flow rate of 150mL / h into the tube furnace 2 Exhaust the air inside, and carbonize in an inert gas Ar atmosphere for 3 hours at a temperature of 750°C to obtain carbon powder;

[0052] (2) Mix the carbon powder and tetraethyl orthosilicate evenly in step (1), wherein the C:Si molar ratio of the carbon powder and tetraethyl orthosilicate is 1.5:1, and add it dropwise at a stirring speed of 600r / min Ammonia water (the solid-to-liquid ratio g:mL of carbon powder and ammonia water is 1.3:0.8, NH in ammonia water 4+ The concentration is 1.56mol / L), ...

Embodiment 3

[0057] Embodiment 3: take calcium gluconate as the CaO precursor, doped with Si prepared from bagasse 3 N 4 Preparation of calcium-based sorbent.

[0058] A high-temperature CO doped with silicon nitride 2 The preparation method of calcium-based adsorbent specifically comprises the following steps:

[0059] (1) Put the wood powder bagasse in a vacuum tube furnace, and feed an inert gas N with a flow rate of 150mL / h into the tube furnace 2 Exhaust the air inside, at a temperature of 800°C, the inert gas N 2 Carbonization reaction in the atmosphere for 4h to obtain carbon powder;

[0060] (2) Mix the carbon powder and tetraethyl orthosilicate evenly in step (1), wherein the C:Si molar ratio of the carbon powder and tetraethyl orthosilicate is 1.5:1, and add it dropwise at a stirring speed of 700r / min Ammonia water (the solid-to-liquid ratio g:mL of carbon powder and ammonia water is 1.6:1, NH in ammonia water 4+ The concentration is 1.65mol / L), the pH value of the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com