Heavy metal adsorbent used for waste water treatment and preparation method and application thereof

A wastewater treatment and adsorbent technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low efficiency of kaolin adsorption of heavy metals, and achieve high reuse times and adsorption The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

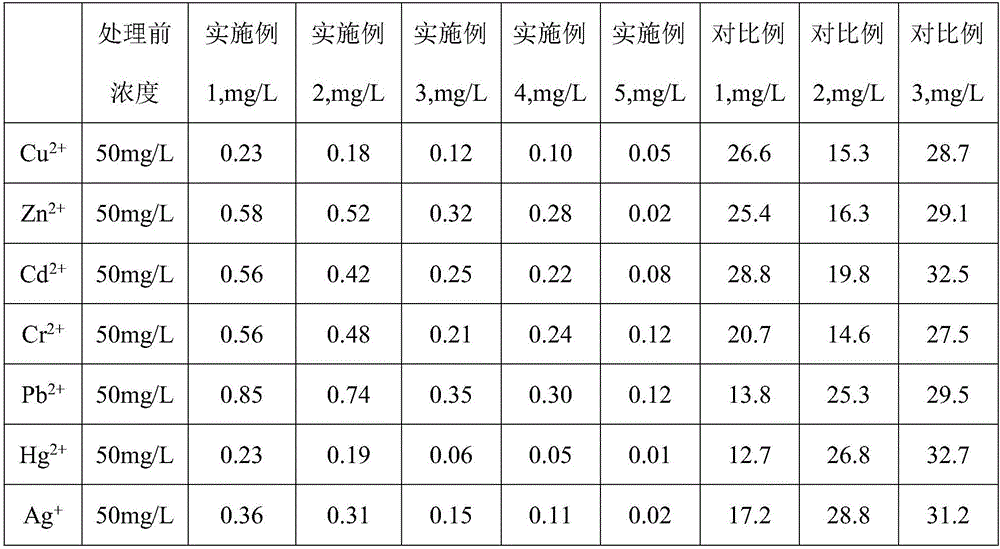

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a heavy metal adsorbent for wastewater treatment is composed of the following raw materials in parts by weight: 31 parts of kaolin, 1 part of thioglycolic acid, 8 parts of acrylamide, and 23 parts of ethylene glycol.

[0018] Mix ethylene glycol with 2.6 times the mass of deionized water to prepare an ethylene glycol solution. The kaolin and acrylamide were mixed and ground, passed through a 120-mesh sieve, then added ethylene glycol solution, heated to 65°C and sonicated at this temperature for 27 minutes, the ultrasonic power was 1000W, and then thioglycolic acid was added dropwise. Warm up to 118℃ and seal and stir at this temperature for 75min, then microwave treatment for 15min, microwave power is 1000W, then stir at 99℃ to dryness, and then calcinate in muffle furnace at 430℃ for 4.3h. Adsorbent.

[0019] Through repeated experiments, it is obtained that the adsorption capacity of the adsorbent is 60-70 mg / g; the adsorbent i...

Embodiment 2

[0021] In the embodiment of the present invention, a heavy metal adsorbent for wastewater treatment is composed of the following raw materials in parts by weight: 39 parts of kaolin, 5 parts of thioglycolic acid, 16 parts of acrylamide, and 31 parts of ethylene glycol.

[0022] Mix ethylene glycol with 2.6 times the mass of deionized water to prepare an ethylene glycol solution. The kaolin and acrylamide were mixed and ground, passed through a 120-mesh sieve, then added ethylene glycol solution, heated to 65°C and sonicated at this temperature for 27 minutes, the ultrasonic power was 1000W, and then thioglycolic acid was added dropwise. Warm up to 118℃ and seal and stir at this temperature for 75min, then microwave treatment for 15min, microwave power is 1000W, then stir at 101℃ to dryness, and then calcinate in muffle furnace at 430℃ for 4.3h. Adsorbent.

[0023] Through repeated experiments, it is obtained that the adsorption capacity of the adsorbent is 60-70 mg / g; the adsorben...

Embodiment 3

[0025] In the embodiment of the present invention, a heavy metal adsorbent for wastewater treatment is composed of the following raw materials in parts by weight: 33 parts of kaolin, 2 parts of thioglycolic acid, 10 parts of acrylamide, and 25 parts of ethylene glycol.

[0026] Mix ethylene glycol with 2.6 times the mass of deionized water to prepare an ethylene glycol solution. The kaolin and acrylamide were mixed and ground, passed through a 120-mesh sieve, then added ethylene glycol solution, heated to 65°C and sonicated at this temperature for 27 minutes, the ultrasonic power was 1000W, and then thioglycolic acid was added dropwise. Warm up to 118°C and seal and stir at this temperature for 75min, then microwave treatment for 15min, microwave power is 1000W, then stir at 100°C to dryness, and then calcinate in a muffle furnace at 430°C for 4.3h. Adsorbent.

[0027] Through repeated experiments, it is obtained that the adsorption capacity of the adsorbent is 65-75 mg / g; the ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com