Magnetic graphene oxide composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and magnetic nanoparticles, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of changing the physical and chemical properties of graphene oxide, affecting the performance of magnetic graphene oxide, and graphene oxide is easy to agglomerate, etc. , to achieve excellent biocompatibility and hydrophilicity, mild conditions, good dispersion and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

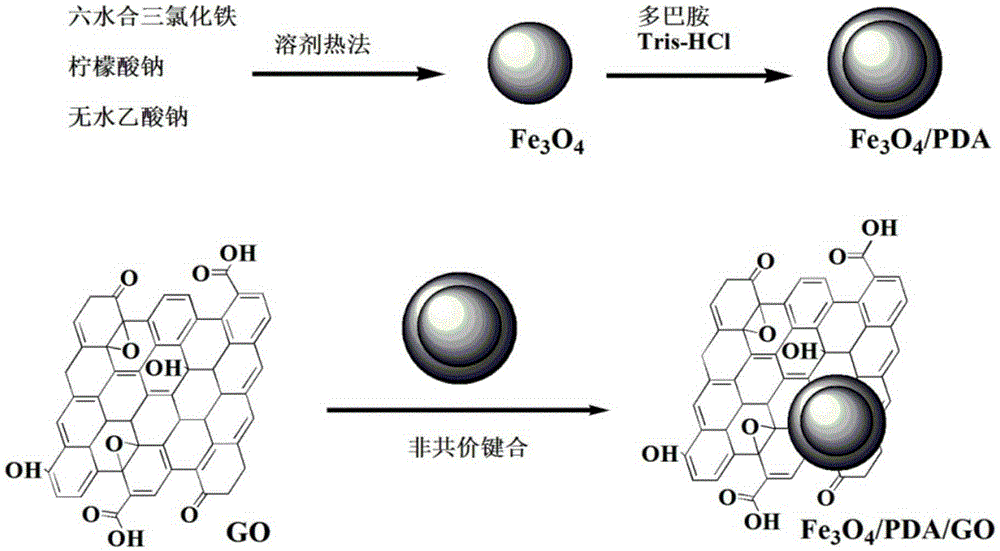

[0039] 1. Preparation of magnetic graphene oxide composite nanomaterials: according to figure 1 As shown, weigh 1.08g of hexahydrate, ferric chloride and 0.2g of sodium citrate, disperse them in 20mL of ethylene glycol, then add 1.2g of anhydrous sodium acetate, stir vigorously for 30min after ultrasonication for 30min, and prepare a uniform solution , and finally loaded into a polytetrafluoroethylene reactor, with a pressure of 5MPa, and reacted at 200°C for 10h. The obtained product was alternately washed three times with deionized water and absolute ethanol, and dried in vacuum at a drying temperature of 60°C and a drying time of 12h. , to prepare citric acid-stabilized magnetic nanoparticles.

[0040] Weigh 10mg of magnetic nanoparticles and disperse them in 50mL of 10mM Tris-HCl buffer solution. The pH of the solution is 8.0. Then add 10mg of dopamine. After shaking evenly, stir and react in a water bath at 25°C for 2h. The anhydrous ethanol was alternately washed three ...

Embodiment 2

[0048] Preparation of Magnetic Graphene Oxide Composite Nanomaterials: According to figure 1 As shown, weigh 1.08g of hexahydrate, ferric chloride and 0.2g of sodium citrate, disperse them in 20mL of ethylene glycol, then add 1.2g of anhydrous sodium acetate, stir vigorously for 30min after ultrasonication for 30min, and prepare a uniform solution , and finally loaded into a polytetrafluoroethylene reactor, pressure 5MPa, reacted at 200°C for 14h, the resulting product was washed alternately with deionized water and absolute ethanol three times, and dried in vacuum at a drying temperature of 60°C and a drying time of 12h , to prepare citric acid-stabilized magnetic nanoparticles.

[0049] Weigh 10 mg of magnetic nanoparticles and disperse them in 50 mL of 10 mM Tris-HCl buffer solution. The pH of the solution is 8.0. Then add 10 mg of dopamine. After shaking evenly, stir and react in a water bath at 25°C for 6 hours. Alternately washing with water and ethanol for three times,...

Embodiment 3

[0052] Preparation of magnetic graphene oxide composite nanomaterials:

[0053] according to figure 1 As shown, weigh 1.08g of hexahydrate, ferric chloride and 0.2g of sodium citrate, and disperse them in 20mL of ethylene glycol, then add 1.2g of anhydrous sodium acetate, stir vigorously for 30min after ultrasonication for 30min, and prepare a uniform solution , and finally loaded into a polytetrafluoroethylene reactor, with a pressure of 5MPa, and reacted at 200°C for 10h. The obtained product was alternately washed with deionized water and absolute ethanol three times, and dried in vacuum at a drying temperature of 60°C and a drying time of 12h. , to prepare citric acid-stabilized magnetic nanoparticles.

[0054] Weigh 10 mg of magnetic nanoparticles and disperse them in 50 mL of 10 mM Tris-HCl buffer solution, the pH of the solution is 8.0, then add 20 mg of dopamine, shake evenly, stir and react in a water bath at 25 °C for 2 h, and wash the product alternately with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com