Method for preparing monoclinic bismuth vanadate visible light catalyst

A technology of monoclinic crystal and visible light, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as inefficient use of sunlight, wide band gap, and difficulty in excitation. Achieve the effect of good crystal form and light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

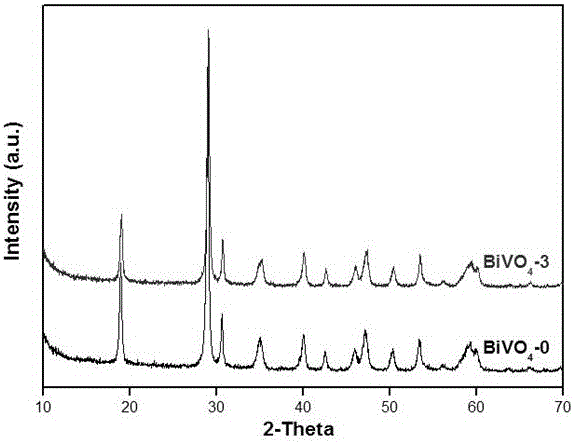

Embodiment 1

[0010] 5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL of HNO with a molar concentration of 1 mol / L 3 Solution A was prepared in the solution; 5mmol NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue to stir for 30min, then transfer the mixed solution into a polytetrafluoroethylene reactor, and react at 180°C After 18 hours, after the reaction was completed, it was naturally cooled to room temperature, separated by filtration, washed with water and ethanol three times respectively, then dried in a constant temperature drying oven at 60°C, and finally calcined at 500°C for 4 hours to obtain a visible photocatalyst of monoclinic bismuth vanadate, labeled for BiVO 4 -0. After 6 hours of natural sunlight irradiation, the decolorization rate of RhB by the bismuth vanadate visible photocatalyst was 86.5%.

Embodiment 2

[0012] 5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL of HNO with a molar concentration of 1 mol / L 3 Solution A was prepared in the solution; 5mmol NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue stirring for 30min, and adjust the pH of the mixture to 1 with NaOH solution with a molar concentration of 2mol / L. Continue to stir for 30 minutes, then transfer the mixed solution into a polytetrafluoroethylene reactor, react at 180 ° C for 18 hours, naturally cool to room temperature after the reaction is completed, filter and separate, wash with water and ethanol three times, and then dry in a constant temperature oven at 60 ℃ drying, and finally calcined at 500 ℃ for 4h to obtain monoclinic bismuth vanadate visible light catalyst, marked as BiVO 4 -1. After 6 hours of natural sunlight irradiation, the decolorization rate of RhB by the bismuth vanadate visible photocatal...

Embodiment 3

[0014] 5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL of HNO with a molar concentration of 1 mol / L 3 Solution A was prepared in the solution; 5mmol NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue stirring for 30 min, and adjust the pH of the mixture to 3 with NaOH solution with a molar concentration of 2mol / L , continue to stir for 30 minutes, then transfer the mixed solution into a polytetrafluoroethylene reactor, and react at 180°C for 18 hours. Dry at 60°C, and finally calcined at 500°C for 4 hours to obtain a monoclinic bismuth vanadate visible light catalyst, marked as BiVO 4 -3. After 6 hours of natural sunlight irradiation, the decolorization rate of RhB by the bismuth vanadate visible photocatalyst was 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com