Temperature-resistant salt-resistant low-tension foaming agent composition as well as preparation method and application thereof

A temperature-resistant, salt-resistant, low-tension technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor foam performance of low-tension surfactants, difficulty in forming stable plugs, and inability to clean up, etc. Achieve the effect of good foam stability, increased salt resistance, and strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

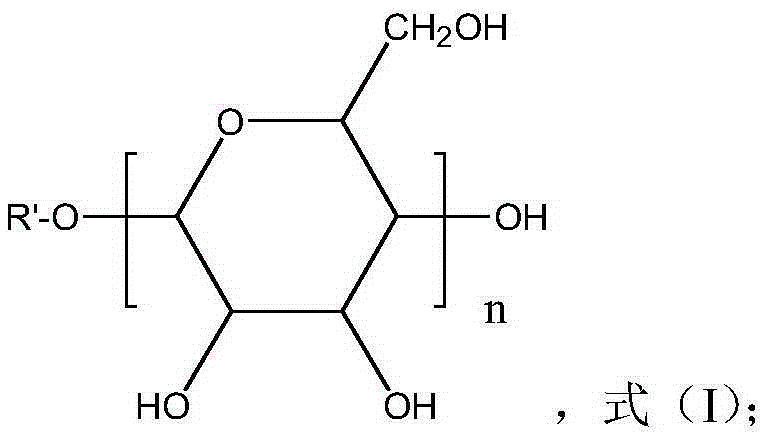

Method used

Image

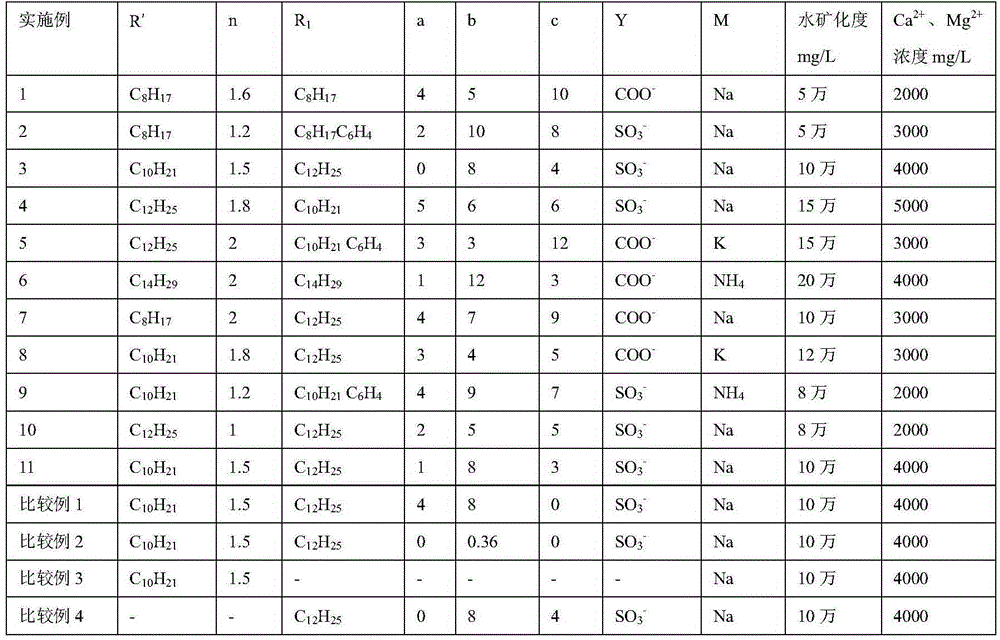

Examples

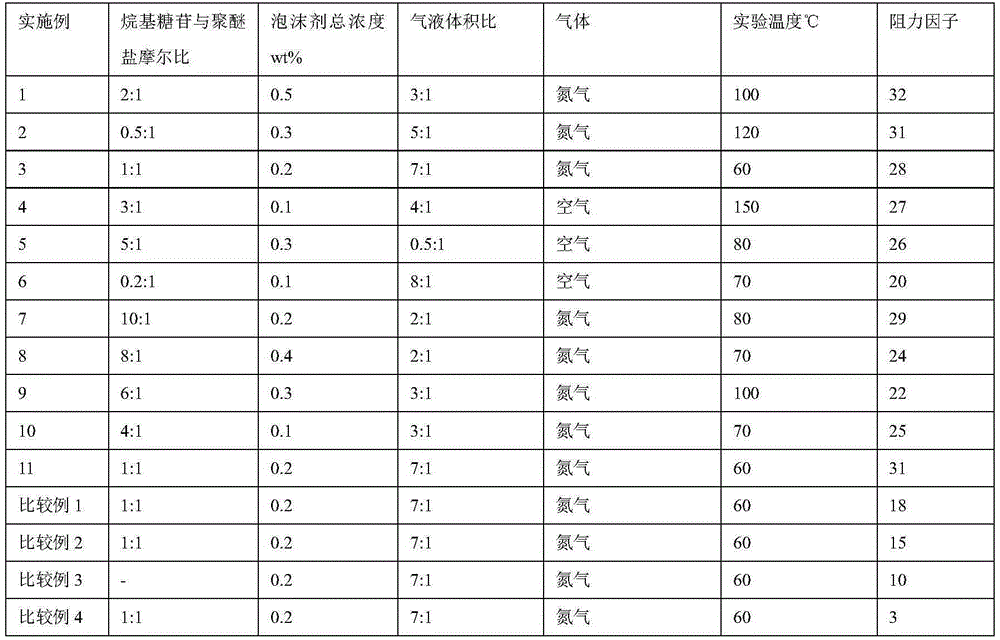

Embodiment 1

[0031] Dissolve the alkyl glucoside and polyether anionic surfactant in the water whose salinity is 50000mg / L and wherein the content of calcium and magnesium ions is 2000mg / L according to the molar ratio of 2:1, and the alkyl glycoside and polyether anionic surfactant Based on the total mass, the mass fraction is 0.5%, and mixed uniformly to form an aqueous foam agent solution, that is, to obtain the temperature-resistant, salt-resistant, low-tension foam agent composition.

[0032] The obtained temperature-resistant, salt-resistant, low-tension foam composition is mixed with nitrogen in a volume ratio of 3:1 to obtain a temperature-resistant, salt-resistant, low-tension foam flooding composition.

[0033] The above composition was taken under the condition of 100°C, and the test of foam plugging capacity was carried out in a sand-filled pipe with a length of 30 cm, a diameter of 3.8 cm, and a permeability of 300 mD. First inject water at a rate of 1mL / min, and record the pre...

Embodiment 2

[0035] Dissolve the alkyl glucoside and polyether anionic surfactant in the water whose salinity is 50000mg / L and wherein the calcium and magnesium ion content is 3000mg / L according to the molar ratio of 0.5:1, and the alkyl glycoside and polyether anionic surfactant Based on the total mass, the mass fraction is 0.3%, and mixed uniformly to form an aqueous foam agent solution, that is, to obtain the temperature-resistant, salt-resistant, low-tension foam agent composition.

[0036] The obtained temperature-resistant, salt-resistant, low-tension foam composition is mixed with nitrogen gas at a volume ratio of 5:1 to obtain a temperature-resistant, salt-resistant, low-tension foam flooding composition.

[0037]The above composition was taken under the condition of 120°C, and the test of foam plugging capacity was carried out in a sand-filled pipe with a length of 30 cm, a diameter of 3.8 cm, and a permeability of 300 mD. First inject water at a rate of 1mL / min, and record the pr...

Embodiment 3

[0039] Dissolve the alkyl glucoside and polyether anionic surfactant in the water with a salinity of 100000mg / L and a calcium and magnesium ion content of 4000mg / L according to the molar ratio of 1:1, and use the alkyl glycoside and polyether anionic surfactant Based on the total mass, the mass fraction is 0.2%, and they are uniformly mixed to form an aqueous solution of the foaming agent, that is, the temperature-resistant, salt-resistant, low-tension foaming agent composition is obtained.

[0040] The obtained temperature-resistant, salt-resistant, low-tension foam composition is mixed with nitrogen gas at a volume ratio of 7:1 to obtain a temperature-resistant, salt-resistant, low-tension foam flooding composition.

[0041] The above composition was taken under the condition of 60°C, and the test of foam plugging ability was carried out in a sand-filled pipe with a length of 30 cm, a diameter of 3.8 cm, and a permeability of 300 mD. First inject water at a rate of 1mL / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com