Tertiary oil recovery oil displacement composition and preparation method thereof

A composition and oil displacement technology, which are applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor oil displacement efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) The amphiphilic head group anionic surfactant structural formula of preparation is as follows, wherein, m 1 +m 2 = 3, n 1 +n 2 =10, m 3 +m 4 =3.

[0081]

[0082] Add 325 grams (1 mole) of behenylamine, 2.3 grams of potassium hydroxide and 8.4 grams of anhydrous potassium carbonate in a 2L pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, Dehydrate under vacuum for 1 hour, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 120°C and slowly introduce 134.2 grams (3.05 moles) of ethylene oxide, control the pressure ≤ 0.60MPa, wait for the reaction of ethylene oxide After the end, adjust the temperature to 130°C and slowly feed 585.8 grams (10.1 moles) of propylene oxide, control the pressure ≤ 0.60MPa, and then adjust the temperature to 140°C and slowly feed 134.2 grams ( 3.05 moles) of ethylene oxide. After the reaction was completed, the temperature was lowered t...

Embodiment 2

[0088] (1) with 【Example 1】, the difference is that behenylamine polyoxyethylene (3) polyoxypropylene (10) polyoxyethylene (3) ether and 3-chloro-2-hydroxypropanesulfonate sodium and After the sodium hydroxide reaction, there is no need to add acidification treatment, that is, heat to 85 ° C for 9 hours, change to a distillation device, distill and remove the solvent, add water and stir the residue evenly, and obtain sodium chloride, excess sodium hydroxide, and excess 3- Sodium Chloro-2-Hydroxypropanesulfonate Sodium Dihydroxypropanesulfonate Surfactant S-2.

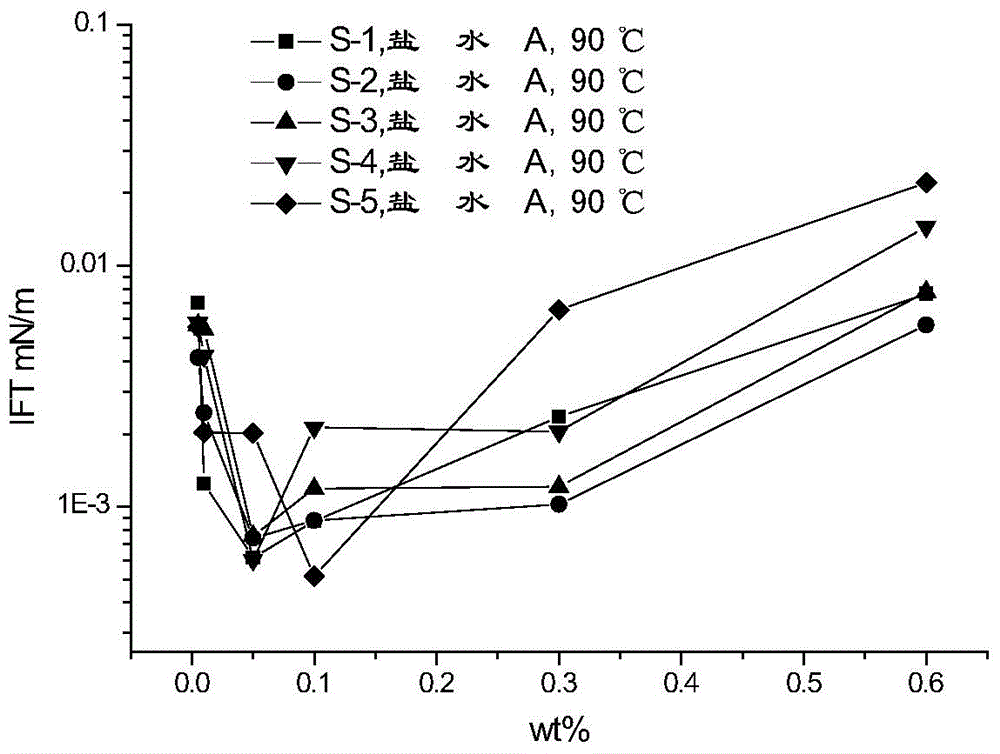

[0089] (2) Prepare the S-2 and modified polyacrylamide (P1, copolymerized AM / AMPS molar ratio = 1 / 1, viscosity-average molecular weight 14.5 million) aqueous solution prepared in step (1) with the simulated formation water A of Zhongyuan Oilfield, and stir 4 hours, all the other are the same as [Example 1] (2), the results are shown in Table 3. The oil-water interfacial tension of different concentrations of S-2 aqueou...

Embodiment 3

[0092] (1) The amphiphilic head group anionic surfactant structural formula of preparation is as follows, wherein, m 1 +m 2 = 3, n 1 +n 2 =10, m 3 +m 4 =3.

[0093]

[0094] Obtain behenylamine polyoxyethylene (3) polyoxypropylene (10) polyoxyethylene (3) ether dihydroxypropanesulfonic acid with [Example 1] (1), the difference is to replace 90% diethanolamine 25% sodium hydroxide aqueous solution adjusts the pH=13 of the system to obtain the desired surface Active agent S-3.

[0095] (2) Prepare the aqueous solutions of S-3 and modified polyacrylamide (P1, copolymerized AM / AMPS molar ratio = 1 / 1, viscosity-average molecular weight 14.5 million) prepared in step (1) with simulated formation water A of Zhongyuan Oilfield, and stir 4 hours, all the other are the same as [Example 1] (2), and the results are shown in Table 4. The oil-water interfacial tension of different concentrations of S-3 aqueous solution is shown in Figure 1.

[0096] (3) Carry out indoor simulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com