Mercury-ion nanometer sensor and preparing method and application thereof

An ion sensor and mercury ion technology are applied in the field of mercury ion nanosensors and their preparation, achieving the effects of high sensitivity, wide application prospects, and omitting sample pretreatment steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

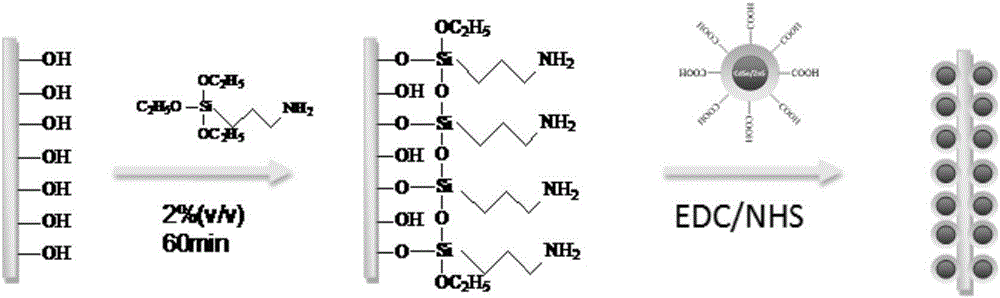

[0036] Embodiment 1, preparation ion sensor

[0037] 1) Remove about 2.5 cm of the coating layer from a silica optical fiber with a diameter of 600 μm and a length of 5 cm, soak the part where the coating layer was removed in 30% hydrofluoric acid, and take out the optical fiber when the diameter is reduced to about 230 μm, At this time, a cone-shaped structure is formed, and the length of the cone angle is about 0.5 cm. The tapered optical fiber can ensure that the fluorescence propagates in the form of total reflection in the optical fiber, thereby improving the transmission efficiency of the fluorescence.

[0038] 2) Hydroxylation of optical fiber: immerse the tapered optical fiber to 30% H 2 o 2 / Concentrated H 2 SO 4 (v / v, 3:1) mixed solution, take out the optical fiber after 30 minutes at room temperature, and fully rinse with ultrapure water until the pH of the cleaning solution is neutral, and finally dry it with nitrogen at room temperature, and store it in a vac...

Embodiment 2

[0042]Embodiment 2, utilizing the ion sensor obtained in embodiment 1 to detect the spiked water sample of mercury ions

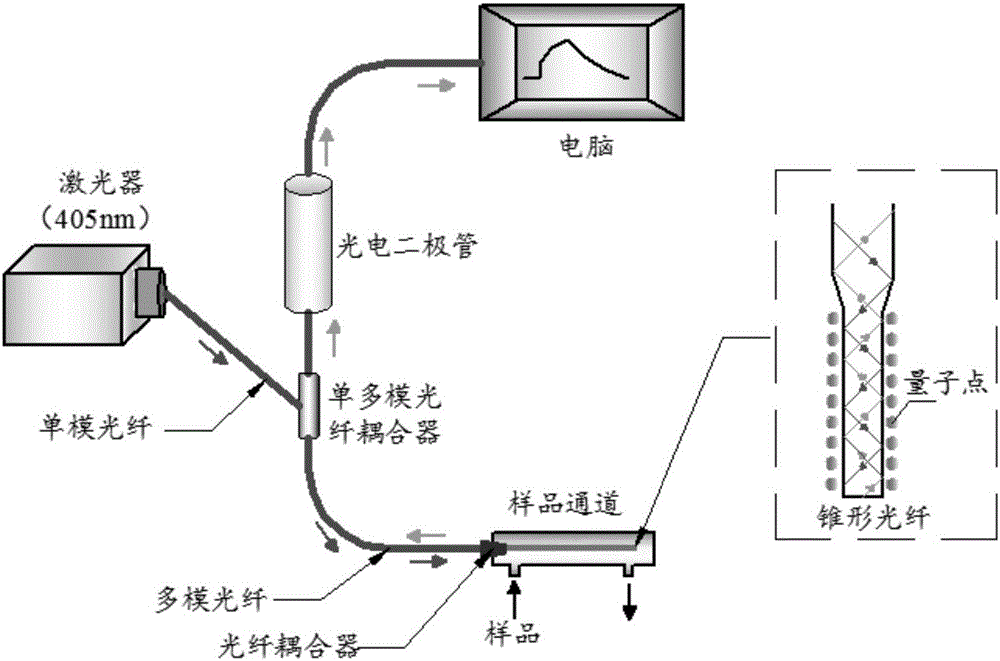

[0043] 1) the ion sensor prepared in embodiment 1 is installed on figure 2 In the sensing platform shown, the tapered end of the optical fiber extends into the sample channel, and the other end is connected to the excitation light transmission device and the fluorescence collection device through a fiber optic coupler to collect the fluorescence signal generated by the detection end and convert it into an electrical signal. signal output;

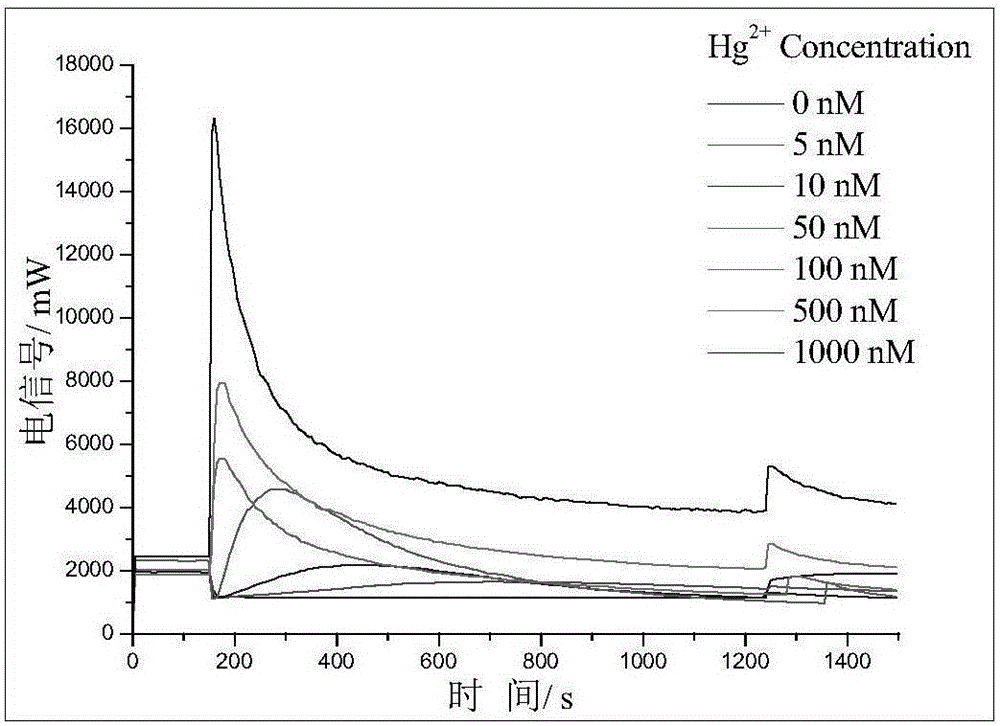

[0044] 2) Inject 200 μl of a series of mercury ion standard solutions with a concentration in the range of 5 to 1000 nM into the sample channel sequentially, and the mercury ions entering the channel will interact with the quantum dots on the surface of the optical fiber, causing the fluorescence intensity to change. After each sample is measured, follow step 1) to replace the optical fiber.

[0045] The real-time sig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com