Neodymium-iron-boron permanent magnet material

A permanent magnet material, NdFeB technology, applied in the direction of magnetic materials, permanent magnet manufacturing, magnetic objects, etc., can solve the problems of easy powder corrosion, low Curie temperature point, poor temperature characteristics, etc., to improve corrosion resistance and mechanical properties, increase coercivity, improve the effect of coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

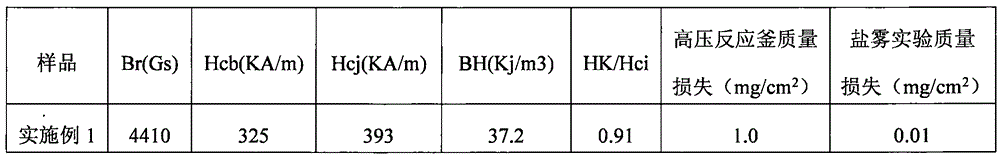

Examples

Embodiment 1

[0027] A NdFeB permanent magnet material is provided, which is prepared by the following method:

[0028] (1) Mix Fe (iron), Nd (neodymium), B (boron), Hf (hafnium), and P (phosphorus) according to the mass ratio of 72:26:1:0.5:0.5, and place the mixed raw materials in the intermediate frequency Vacuum induction melting furnace for melting, the heat treatment temperature is 1200 °C, and the sintering time is 2 hours to obtain rare earth permanent magnet ingots;

[0029] (2) processing the rare earth permanent magnet ingot obtained in step (1) into rare earth magnetic powder with an average particle diameter of 1 μm through hydrogen explosion and jet milling;

[0030] (3) Get 80g of the rare earth magnetic powder and 5g of 100-purpose Zn-Al alloy powder, use a plasma processor, plasma process 20min under the radio frequency power of 60W, the gas that feeds in the plasma processor chamber is argon Gas, the gas flow rate is 10ml / s, and the cavity pressure is maintained at 0.2Pa;...

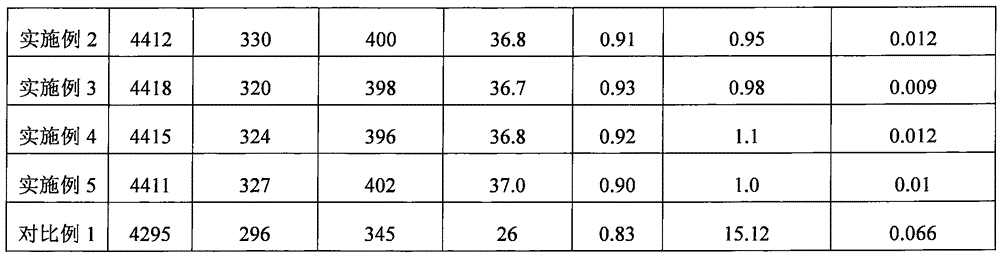

Embodiment 2

[0036] A NdFeB permanent magnet material is provided, which is prepared by the following method:

[0037] (1) Mix Fe (iron), Nd (neodymium), B (boron), Hf (hafnium), and P (phosphorus) according to the mass ratio of 72:26:1:0.5:0.5, and place the mixed raw materials in the intermediate frequency Vacuum induction melting furnace for melting, the heat treatment temperature is 1250°C, and the sintering time is 2.5 hours to obtain rare earth permanent magnet ingots;

[0038] (2) processing the rare earth permanent magnet ingot obtained in step (1) into rare earth magnetic powder with an average particle diameter of 1.5 μm through hydrogen explosion and jet milling;

[0039] (3) Get the described rare earth magnetic powder of 80g and the 200 mesh Zn-Al alloy powder of 5g, use the plasma processing instrument, be that the radio frequency power is 60W plasma processing 20min, the gas that feeds in the plasma processing instrument cavity is argon Gas, the gas flow rate is 10ml / s, and...

Embodiment 3

[0045] A NdFeB permanent magnet material is provided, which is prepared by the following method:

[0046] (1) Mix Fe (iron), Nd (neodymium), B (boron), Hf (hafnium), and P (phosphorus) according to the mass ratio of 72:26:1:0.5:0.5, and place the mixed raw materials in the intermediate frequency Vacuum induction melting furnace for melting, the heat treatment temperature is 1250°C, and the sintering time is 2.5 hours to obtain rare earth permanent magnet ingots;

[0047] (2) processing the rare earth permanent magnet ingot obtained in step (1) into rare earth magnetic powder with an average particle diameter of 1.5 μm through hydrogen explosion and jet milling;

[0048] (3) get the described rare earth magnetic powder of 80g and the 300 purpose Zn-Al alloy powder of 5g, use plasma processor, under radio frequency power is 150W plasma process 25min, the gas that feeds in the plasma processor cavity is argon Gas, the gas flow rate is 70ml / s, and the cavity pressure is maintaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com