Lithium ion battery positive electrode material and preparation method and application thereof

A battery positive electrode, potassium ion technology, applied in the direction of battery electrodes, electrolyte storage battery manufacturing, batteries, etc., to achieve good application prospects, low cost, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

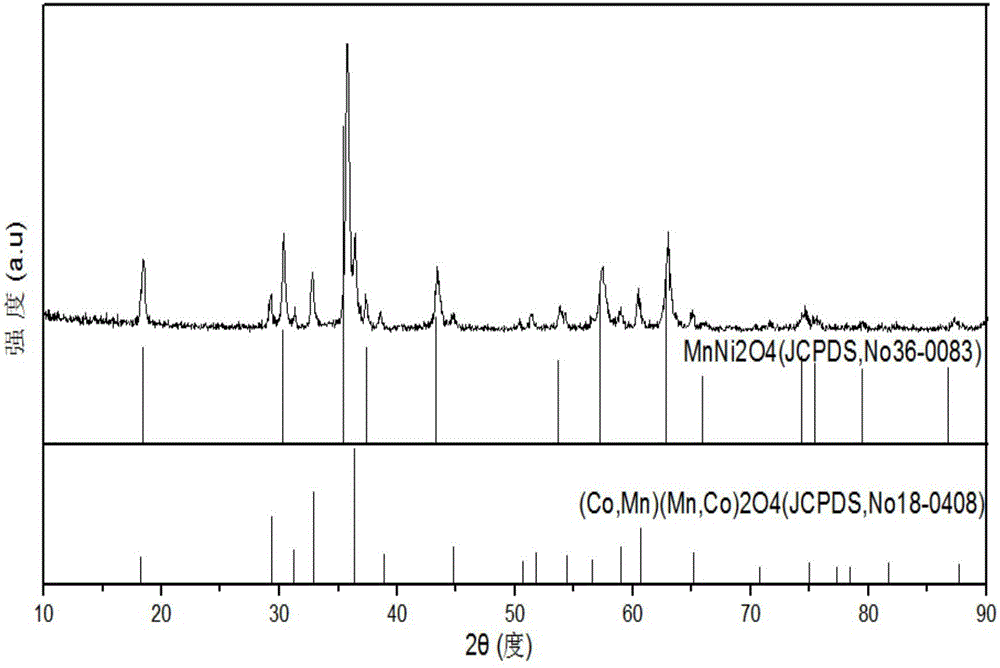

[0032] A kind of potassium ion battery K 0.67 (Ni 0.167 co 0.167 mn 0.666 )O 2 A method for preparing a positive electrode material, comprising the steps of:

[0033] (1) 43.90g of nickel sulfate hexahydrate, 46.94g of cobalt sulfate heptahydrate and 131.81g of manganese chloride tetrahydrate were dissolved in 1L of deionized water, stirred and dissolved evenly to obtain a mixed metal ion salt solution;

[0034] (2) pump the mixed metal ion salt solution that step (1) obtains into the continuous stirred tank reactor with a peristaltic pump, and add 106g concentration simultaneously and be the sodium carbonate solution of 1.0mol / L; Add ammoniacal liquor to adjust the pH value to 8, react The temperature of the solution in the vessel was controlled at 60°C, protected by nitrogen, and continuously stirred at a speed of 500rmp for 4 hours to obtain a carbonate precursor solution;

[0035] (3) Filter the carbonate precursor solution obtained in step (2), wash it repeatedly wit...

Embodiment 2

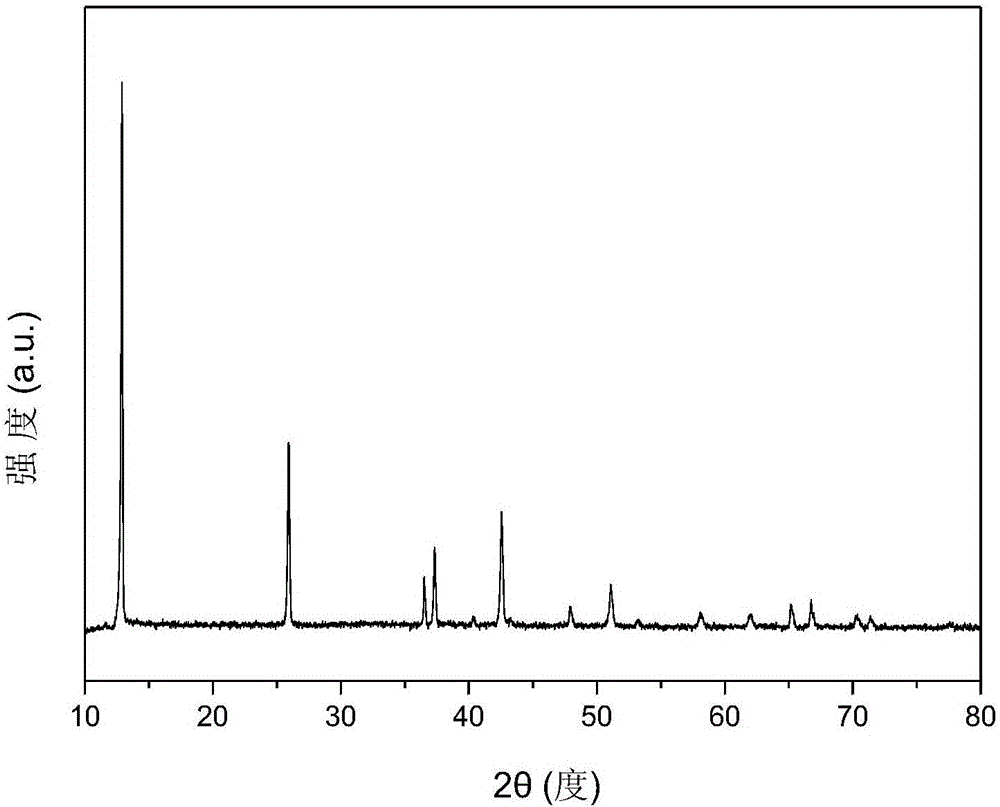

[0041] A kind of potassium ion battery K 0.67 (Ni 0.45 co 0.45 mn 0.1 )O 2 A method for preparing a positive electrode material, comprising the steps of:

[0042] (1) Dissolve 106.96g nickel chloride hexahydrate, 107.07g cobalt chloride hexahydrate and 19.79g manganese chloride tetrahydrate in 1L deionized water, stir and dissolve evenly to obtain a mixed metal ion salt solution;

[0043] (2) pump the mixed metal ion salt solution that step (1) obtains into the continuous stirred tank reactor with a peristaltic pump, add 312g concentration simultaneously and be the sodium carbonate solution of 2.0mol / L; Add ammoniacal liquor to adjust the pH value to 10, react The temperature of the solution in the container was controlled at 55°C, protected by nitrogen, and stirred continuously at a speed of 550rmp for 6 hours to obtain a carbonate precursor solution;

[0044] (3) Filter the carbonate precursor solution obtained in step (2), wash it repeatedly with deionized water 5 time...

Embodiment 3

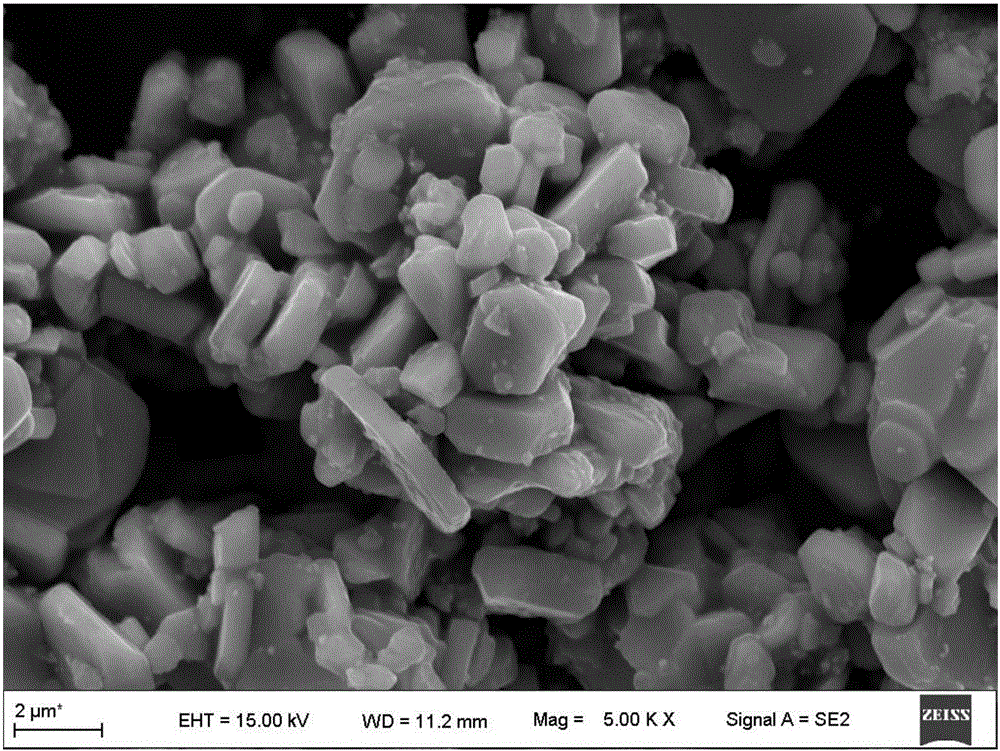

[0047] A kind of potassium ion battery K 0.67 (Ni 0.45 co 0.21 mn 0.34 )O 2 A method for preparing a positive electrode material, comprising the steps of:

[0048] (1) 118.28g nickel sulfate hexahydrate, 59.03g cobalt sulfate heptahydrate and 57.46g manganese sulfate monohydrate were dissolved in 1L deionized water, stirred and dissolved evenly to obtain mixed metal ion salt solution;

[0049] (2) pump the mixed metal ion salt solution that step (1) obtains into the continuous stirred tank reactor with a peristaltic pump, add 159g concentration simultaneously and be the sodium carbonate solution of 1.5mol / L; Add ammoniacal liquor to adjust the pH value to 11, react The temperature of the solution in the vessel was controlled at 60°C, protected by argon, and stirred continuously at a speed of 800rmp for 8 hours to obtain a carbonate precursor solution;

[0050] (3) Filter the carbonate precursor solution obtained in step (2), wash it repeatedly with deionized water 5 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com