Denitration method for cracked flue gas produced in production of low-carbon olefin through steam cracking

A technology for cracking flue gas and low-carbon olefins, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as ammonia leakage, complex system, and large investment, and achieve Saving resources, good denitrification effect, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The supported Pd-Pt series catalyst can be commercially available, and can also be prepared by conventional methods in the art. Preferably, the preparation method of the supported Pd-Pt series catalyst comprises:

[0030] (a-1) Coating the slurry of pseudo-boehmite on honeycomb cordierite (honeycomb cordierite ceramics can be used), drying and firing to obtain honeycomb cordierite with aluminum-containing coating, and as a carrier;

[0031] (b-1) Coating a solution containing a palladium compound and a platinum compound on the above carrier, drying and calcining to prepare a supported Pd-Pt catalyst.

[0032] Wherein, the palladium-containing compound may be, for example, one or more of palladium nitrate, palladium chloride, sodium tetrachloropalladate and palladium acetylacetonate. The platinum-containing compound may be, for example, one or more of chloroplatinic acid, potassium tetrachloroplatinate and potassium hexachloroplatinate. The solvent of the solution used...

preparation example 1

[0056] This preparation example is used to illustrate the supported Pd-Pt catalyst used in the present invention.

[0057] (a) 100g of pseudo-boehmite powder (purchased from Zibo Taiguang Chemical Co., Ltd. GL-1 brand) and 400g of water were ball milled at a speed of 50rpm in a ball mill (Nanjing Laibu Technology Industrial Co., Ltd. QM model) for 2h to obtain Suspended slurry, the slurry was coated on 1000g honeycomb cordierite ceramics (purchased from Jiangxi Xingfeng Chemical Packing Co. extruded in a bar machine, and then calcined at 700°C for 6h to obtain a γ-Al 2 o 3 Coated honeycomb cordierite support.

[0058] (b) immersing the carrier obtained in step (a) in an aqueous solution containing 1% by weight of chloroplatinic acid and 1% by weight of palladium chloride for 12h, then drying at 120°C for 4h, and then calcining at 500°C for 4h, Thereby making Pd / Pt-Al 2 o 3Catalyst C1, based on the total amount of the catalyst, the content of Pd element is 0.5% by weight, ...

Embodiment 1

[0060] This example is used to illustrate the denitrification method for pyrolysis flue gas of the present invention.

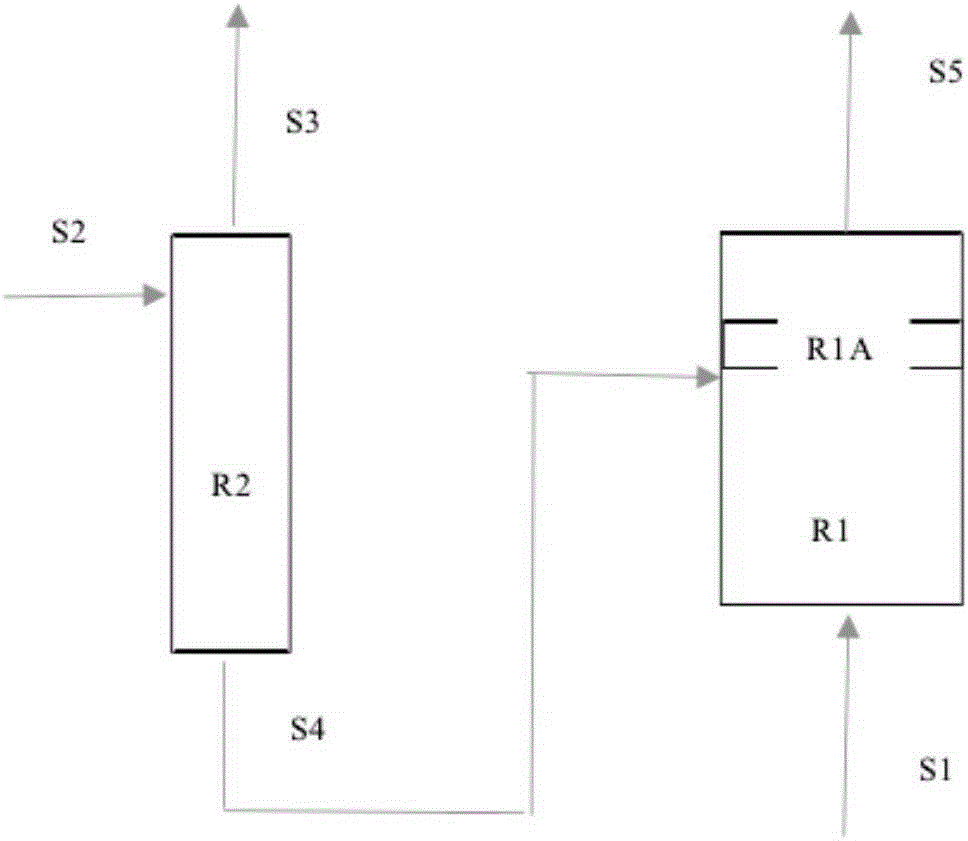

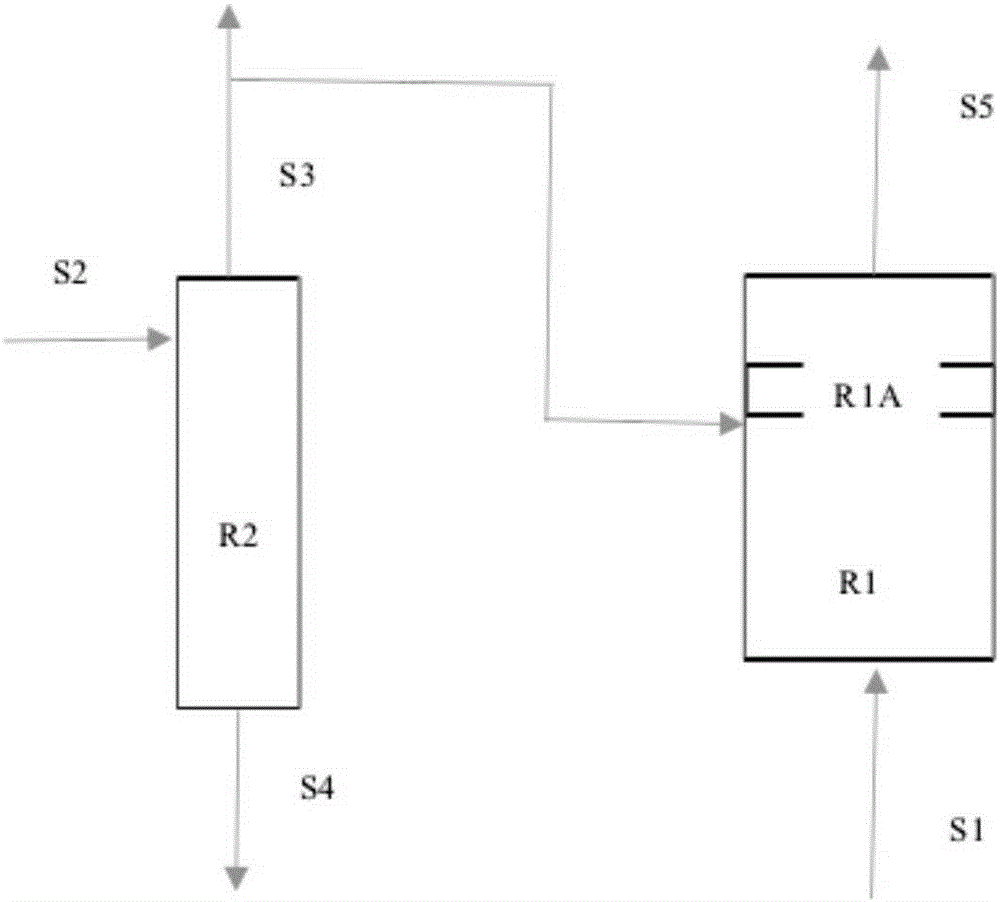

[0061] use figure 1 The denitrification system shown, in which, the crude hydrogen obtained by cryogenic separation is passed through the pressure swing adsorption bed to obtain purified hydrogen and analytical gas, the purified hydrogen is discharged from the upper port of the pressure swing adsorption bed, and the analytical gas is discharged from the pressure swing adsorption bed. The lower opening of the adsorption bed is discharged and enters the cracking furnace flue from the inlet of the analysis gas configured on the cracking furnace flue, and enters the denitrification bed with the cracking flue gas entering from the bottom of the cracking furnace flue (CBL- Type III) for contact and denitrification, and then the denitrified pyrolysis flue gas is discharged from the top outlet of the cracking furnace flue, wherein:

[0062] Analytical gas, H 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com