High-temperature sintering type sulfur-containing iron-based catalyst and preparation method thereof

An iron-based catalyst, high-temperature sintering technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve low-carbon olefin selectivity and CO conversion rate Low, poor thermal stability and other problems, to achieve the effect of improving selectivity, improving activity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

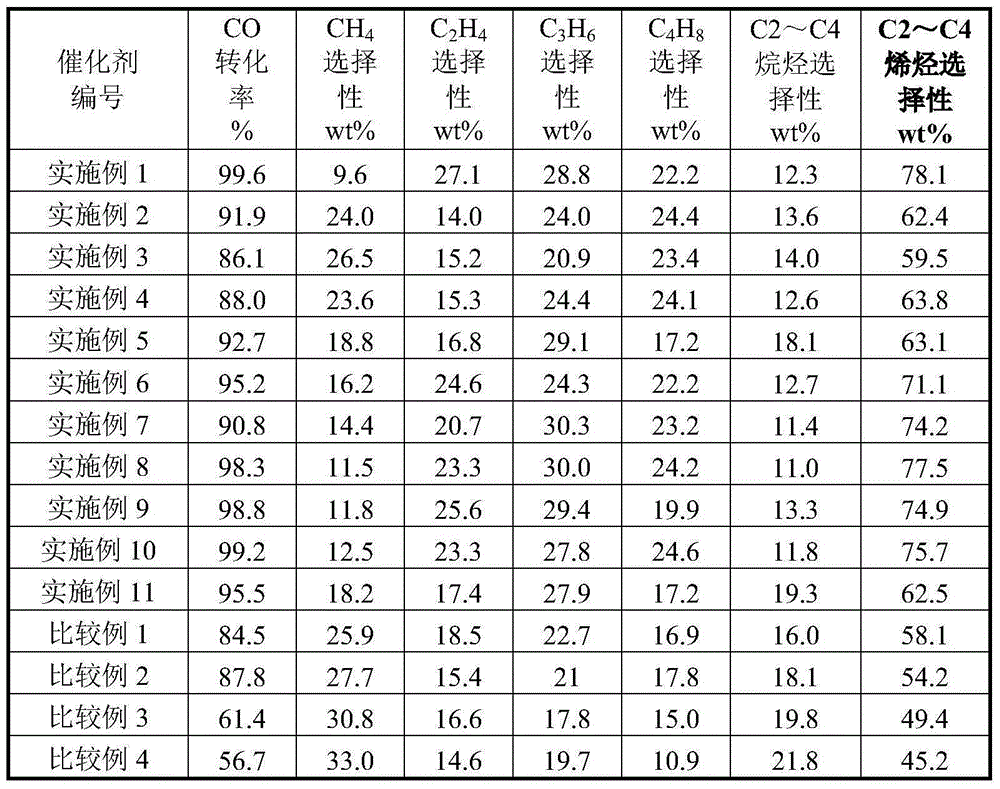

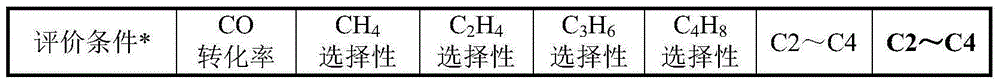

Examples

Embodiment 1

[0028] Weigh 30.0 grams of ferric oxide (Fe 3 o 4 ), 8.0 grams of ruthenium dioxide (RuO 2 ), 20.0 grams of calcium oxide (CaO), 16.0 grams of vanadium pentoxide (V 2 o 5 ), 26.0 grams of α-alumina (α-Al 2 o 3 ) and trace CaSO 4 And according to the total amount of raw materials, 4 grams of methyl cellulose with a percentage by weight of 4%, were ground and mixed for 4 hours in a ball mill; kneading until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment. Dry at ℃ for 12 hours for later use; put the dried precursor into a high-temperature furnace, calcinate at 1300℃ for 6.0 hours, and after cooling, crush and sieve into 20-40 meshes to obtain the required high-temperature sintered sulfur-containing iron-based catalyst. The obtained iron-based catalyst comprises the following components in weight percent: 30% Fe 3 o 4 , 8% ...

Embodiment 2

[0030] Weigh 52.0 grams of ferric oxide (Fe 3 o 4 ), 0.5 g ruthenium dioxide (RuO 2 ), 9.0 grams of calcium oxide (CaO), 9.0 grams of vanadium pentoxide (V 2 o 5 ), 29.5 grams of α-alumina (α-Al 2 o 3 ) and trace CaSO 4 And according to the total amount of raw materials, 4 grams of methyl cellulose with a percentage by weight of 4% were ground and mixed for 6 hours in a ball mill; kneading until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment. Dry at ℃ for 12 hours for later use; send the dried precursor into a high-temperature furnace, calcinate at 1000℃ for 6.0 hours, and after cooling, crush and sieve into 20-40 meshes to obtain the required high-temperature sintered sulfur-containing iron-based catalyst. The obtained iron-based catalyst comprises the following components in weight percent: 52% Fe 3 o 4 , 0.5% RuO 2 ...

Embodiment 3

[0032] Weigh 10.0 grams of ferric oxide (Fe 3 o 4 ), 16.0 grams of ruthenium dioxide (RuO 2 ), 25.0 grams of calcium oxide (CaO), 32.0 grams of vanadium pentoxide (V 2 o 5 ), 17.0 grams of α-alumina (α-Al 2 o 3 ) and trace CaSO 4 And according to the total amount of raw materials, 4 grams of methyl cellulose with a percentage by weight of 4%, were ground and mixed for 2 hours in a ball mill; kneading until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment. Dry at ℃ for 12 hours for later use; put the dried precursor into a high-temperature furnace, calcinate at 1300℃ for 6.0 hours, and after cooling, crush and sieve into 20-40 meshes to obtain the required high-temperature sintered sulfur-containing iron-based catalyst. The obtained iron-based catalyst comprises the following components in weight percent: 10% Fe 3 o 4 , 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com