A kind of Lactobacillus brucei which can improve the quality of feed silage and its application

A technology of Lactobacillus brucei and feed, which is applied to the preservation method, application, and animal feed of animal feed materials. It can solve the problems of limited silage effect, differences in optimal growth conditions for different strains, and high preparation costs, and achieve improved silage production. The effect of fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

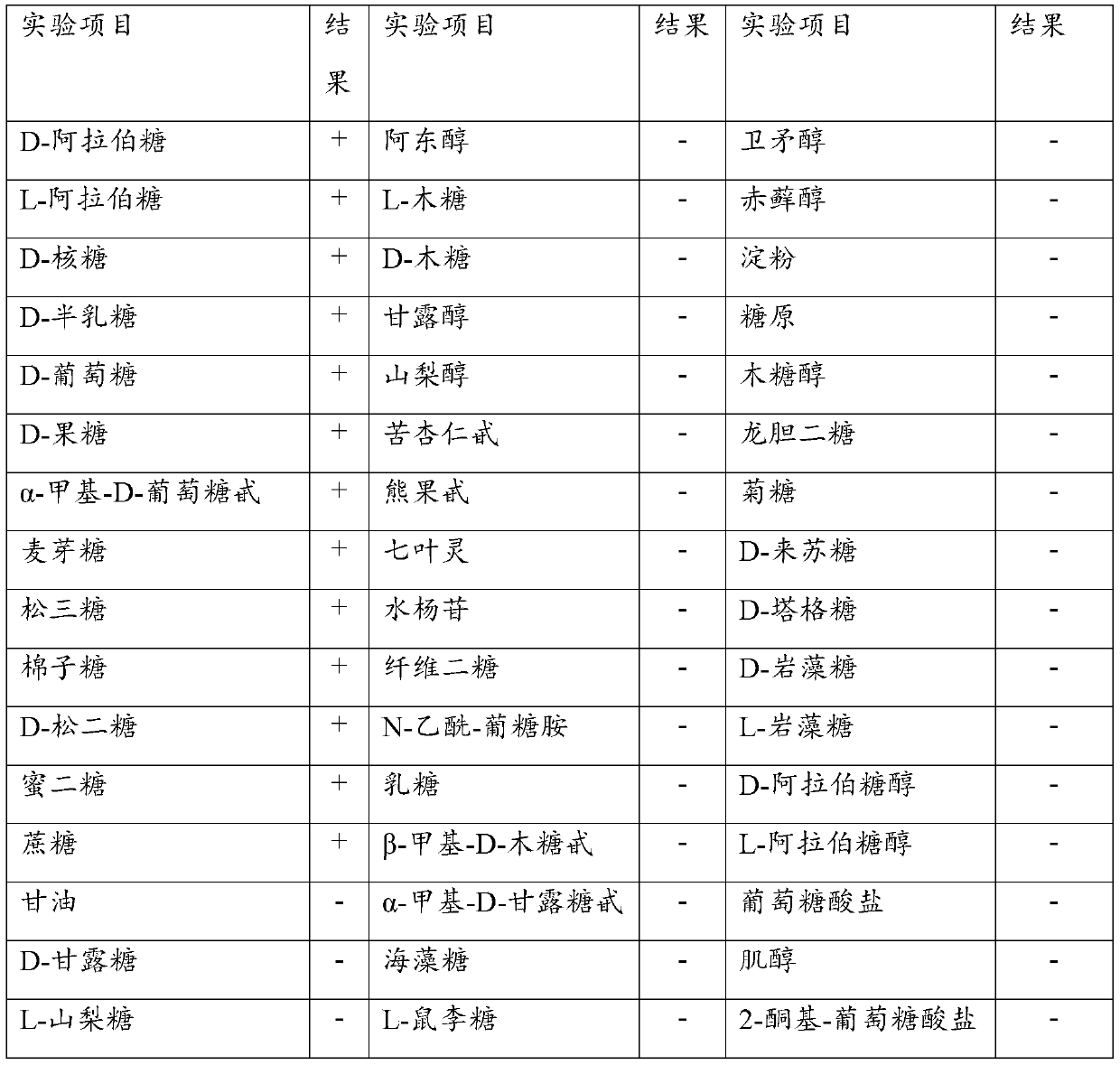

[0025] The screening of embodiment 1 Lactobacillus Brucella and the preparation of bacterial agent

[0026] An excellent strain of Lactobacillus Brucella H4001 was isolated from sika deer silage. Take 30g of mixed silage of corn pasture branches and leaves, add 270ml of sterile water, shake on a shaker at 227rpm / min for 60min, fully stir with a stirrer, gradiently dilute, separate and cultivate by pouring culture method, and cultivate at 37°C for 72h to select colonies with calcium-dissolving circles. The 5-6th generation was purified by streaking on a plate, examined under a microscope, and the purified lactic acid bacteria were inserted into the improved MRS liquid medium to detect their microbiological characteristics, such as morphology, physiological characteristics (Table 1) and sugar catabolism ( Table 2) Capabilities. With the isolated strain as the core material, after 18-24 hours of anaerobic fermentation, 4°C, 3000g / rpm centrifugal concentration, add 100ml of freez...

Embodiment 2

[0036] Example 2 Effect of lactic acid bacteria preparation on fermentation quality of alfalfa silage

[0037] On August 14, 2014, a 5-year-old alfalfa in full-flowering stage was taken from Zhenglan Banner, Xilingol League, Inner Mongolia. It was wilted in the sun for 6 hours, cut into 3-4cm sections, and sprayed with Lactobacillus Brucella H4001. Culture solution, the number of bacteria added is about 5×10 per gram of mixed forage 5 cfu, the control group added the same amount of sterile water. Fully mix the sprayed silage raw materials, take about 900g and put it into a 1000ml silage bottle, press it tightly and seal it. After 60 days of fermentation, the quality of silage fermentation was tested.

[0038] Table 3 Effect of adding Lactobacillus brucella H4001 on the pH value and organic acid content of alfalfa silage

[0039]

[0040] It can be seen from the results that the addition of Lactobacillus brauchneri can effectively reduce the pH value of silage, but the di...

Embodiment 3

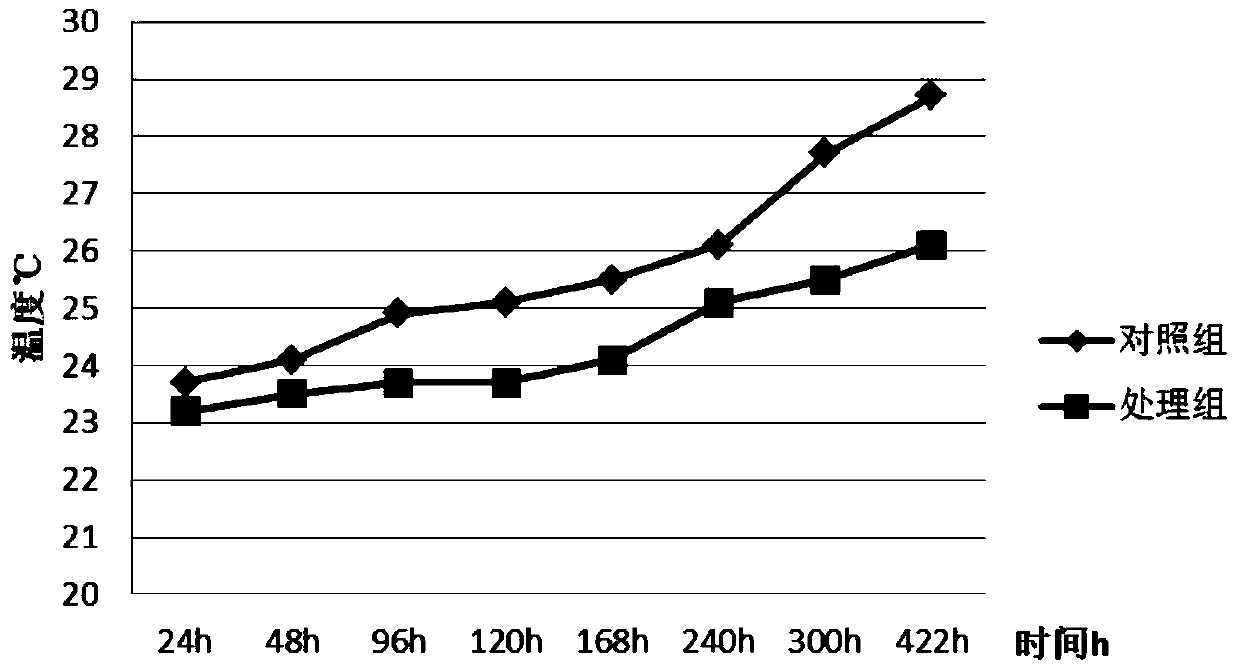

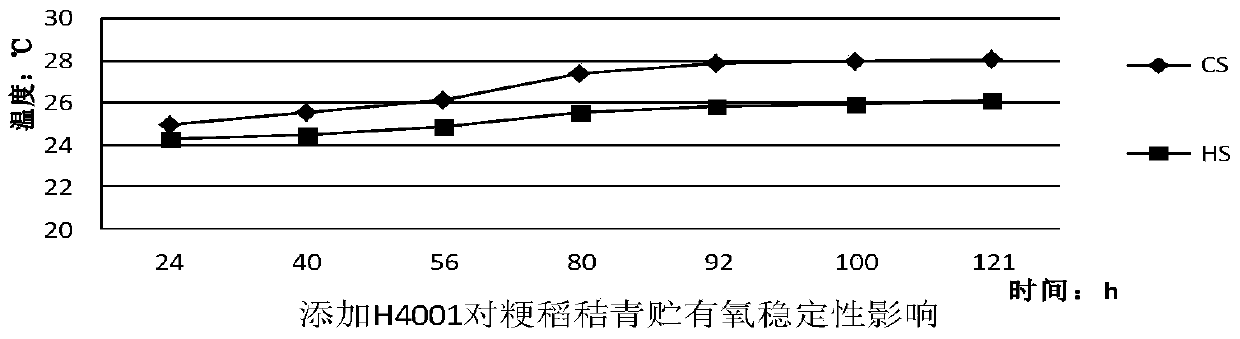

[0045] Example 3 Effects of Different Lactic Acid Bacteria on the Fermentation Quality of Japonica Rice Straw

[0046] On September 30, 2015, the japonica rice straw was harvested from Xiaotang Village, Zuojia Town, Jilin City, Jilin City, Jilin Province. It was cut 4-5cm away from the ground, wilted in the sun for 6 hours, cut into 3-4cm sections with an agricultural forage grinder, and sprayed. Lactobacillus Brucella culture solution, the number of added bacteria is about 5×10 per gram of mixed grass 5 cfu, the control group added the same amount of sterile water. Fully mix the sprayed silage raw materials, take about 800-900g and put it into a 1000ml silage bottle, press it tightly and seal it. After 60 days of fermentation, the quality of silage fermentation was tested. The results are shown in Table 5-6 and figure 2 shown.

[0047] Table 5 Effects of adding Lactobacillus Brucella on the pH value and organic acid content of japonica rice straw silage

[0048]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com