Nano-mesoporous granular drug carrier with photothermal effect and preparation method of nano-mesoporous granular drug carrier

A nano-mesoporous, photothermal effect technology, applied in the directions of non-active ingredients medical preparations, active ingredients-containing medical preparations, drug combinations, etc. Achieve good photothermal effect, good encapsulation effect, and not easy to leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The specific steps of the preparation method of the nano-mesoporous particle drug carrier capable of efficiently delivering anticancer drugs and photothermal effects are as follows:

[0037]Step 1, completely dissolve the surfactant and co-solvent triethanolamine in water at 80°C, then slowly add silicon source and stir rapidly for 1-4 hours, centrifuge to obtain white colloidal particles, wash with ethanol several times and dry, after drying The product is calcined to remove the organic template to obtain nanometer mesoporous silica particles. The molar ratio of each reactant is: 1~5 surfactant: 10~50 silicon source: 1~10 cosolvent: 2000~6000 water;

[0038] Step 2: Add the nanometer mesoporous silica particles and aminosilane coupling agent obtained in step 1 into anhydrous toluene at a ratio of 1g / 0.2ml~1g / 2ml, and stir at 120°C for 12~ For 48 hours, filter, wash with toluene, wash with absolute ethanol, and dry to obtain amino-modified nanometer mesoporous silica pa...

Embodiment 1

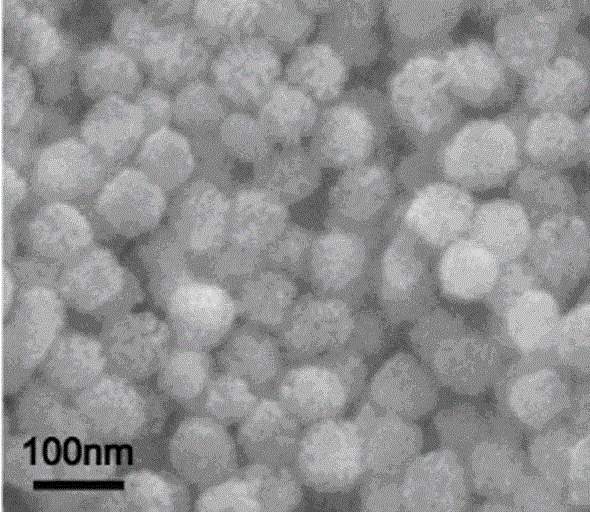

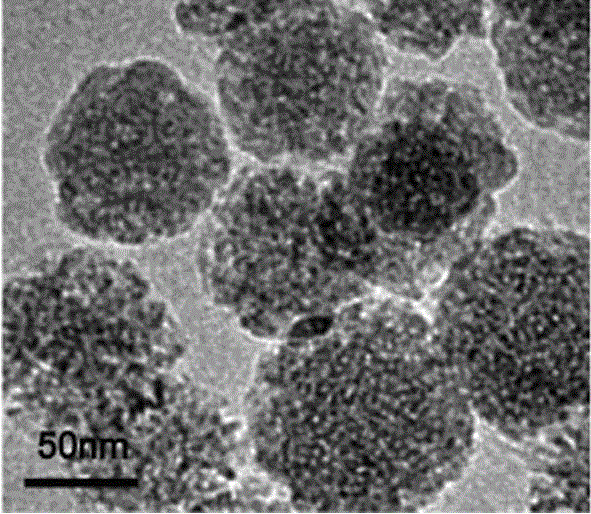

[0044] The nano-mesoporous particle drug carrier provided in this embodiment includes nano-mesoporous silicon oxide particles and graphene oxide quantum dots adsorbed on the surface of the nano-mesoporous silicon oxide particles. The preparation method of the nano-mesoporous particle drug carrier comprises the following steps:

[0045] Step 1, dissolve 0.6836 g of cetyltrimethylammonium p-toluenesulfonate and 0.4 g of triethanolamine in 60 ml of deionized water; then slowly add 4 ml of ethyl orthosilicate at a reaction temperature of 80°C; continue After rapid stirring for 2 hours, centrifuge to obtain white colloidal particles, wash with ethanol several times and then vacuum-dry at 60°C. The dried white colloidal particles are calcined at 650°C for 6 hours to remove surfactants and obtain nanometer mesoporous silica particles ;

[0046] Step 2: Disperse 0.5 g of the nanometer mesoporous silica particles obtained in Step 1 in 80 ml of toluene and stir at 120° C. for 1 hour, t...

Embodiment 2

[0058] The preparation method of the nano-mesoporous particle drug carrier provided in this embodiment includes the following steps:

[0059] Step 1, 0.5466 gram cetyltrimethylammonium bromide and 0.4 gram triethanolamine are dissolved in 60 milliliters of deionized water; Then in 80 oC Slowly add 5 milliliters of tetraethyl orthosilicate at the reaction temperature; after continuing to stir rapidly for 2 hours, centrifuge to obtain white colloidal particles, wash with ethanol several times and then at 60 o C under vacuum drying, the white colloidal particles after drying at 650 o Calcining at C for 6h to remove the surfactant to obtain nanometer mesoporous silicon oxide particles;

[0060] Step 2, 0.5 gram of nano-mesoporous silica particles obtained in Step 1 are dispersed in 80 milliliters of toluene and heated at 120 o C stirred for 1 hour, then 0.75 ml of γ-aminopropyltriethoxysilane was added rapidly and continued at 120 oC stirred for 24 hours; adopt high-speed centr...

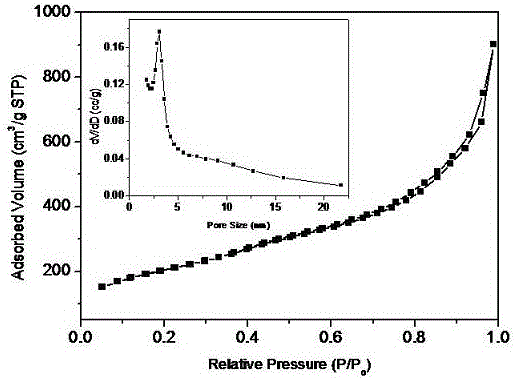

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com