Preparation method of quadrangular bismuth vanadate/graphene composite photocatalyst

A graphene composite and photocatalyst technology, which is applied in the synthesis of composite photocatalytic materials, can solve the problems of easy aggregation of nanoparticles, restrictions on the industrial application of nanophotocatalytic technology, narrow absorption spectrum range, etc., and achieve good crystal form and light absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

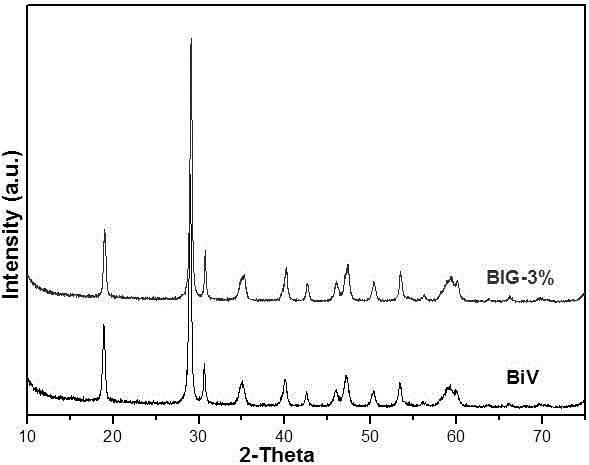

Embodiment 1

[0010] 5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL of HNO with a molar concentration of 1 mol / L 3 Solution A was prepared in the solution; 5mmol NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue stirring for 30min, and adjust the pH of the mixed solution to 3 with NaOH solution with a molar concentration of 2mol / L. Continue to stir for 30 minutes, then transfer the mixture into a polytetrafluoroethylene reactor, react at 180°C for 18 hours, naturally cool to room temperature after the reaction is completed, filter and separate, wash with water and ethanol three times, then dry, and finally calcined at 500°C After 4h, a tetragonal monoclinic bismuth vanadate catalyst with visible light was prepared, marked as BIV. After 3h 500W Xe lamp visible light irradiation, the tetragonal monoclinic bismuth vanadate photocatalyst has a decolorization rate of 73.2% for RhB.

Embodiment 2

[0012] Disperse 0.0162g of graphene oxide in 15mL of HNO with a molar concentration of 1mol / L 3 solution, ultrasonic 2h, then magnetic stirring, and then 2.425g Bi(NO 3 ) 3 ·5H 2 O was added to the above solution, magnetically stirred until completely dissolved to obtain solution A; 0.585g NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue stirring for 30min, and adjust the pH of the mixed solution to 3 with NaOH solution with a molar concentration of 2mol / L. Continue to stir for 30 minutes, then transfer the mixture into a polytetrafluoroethylene reactor, react at 180°C for 18 hours, naturally cool to room temperature after the reaction is completed, filter and separate, wash with water and ethanol three times, then dry, and finally calcined at 500°C After 4h, the tetragonal bismuth vanadate / graphene composite photocatalyst was prepared, labeled as BIG-1%. After 3h 5...

Embodiment 3

[0014] Disperse 0.0486g of graphene oxide in 15mL of HNO with a molar concentration of 1mol / L 3 solution, ultrasonic 2h, then magnetic stirring, and then 2.425g Bi(NO 3 ) 3 ·5H 2 O was added to the above solution, magnetically stirred until completely dissolved to obtain solution A; 0.585g NH 4 VO 3 Solution B was prepared by dissolving in 40mL water under ultrasonic conditions; under stirring conditions, add solution B to solution A, continue stirring for 30min, and adjust the pH of the mixed solution to 3 with NaOH solution with a molar concentration of 2mol / L. Continue to stir for 30 minutes, then transfer the mixture into a polytetrafluoroethylene reactor, react at 180°C for 18 hours, naturally cool to room temperature after the reaction is completed, filter and separate, wash with water and ethanol three times, then dry, and finally calcined at 500°C After 4h, the tetragonal bismuth vanadate / graphene composite photocatalyst was prepared, labeled as BIG-3%. After 3h 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com