Method for preparing open pore foamed aluminum through investment casting

A technology of through-hole aluminum foam and investment mold, which is used in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of poor pore penetration rate, easy corrosion, and unsatisfactory fluid distribution effect, etc. Excellent and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

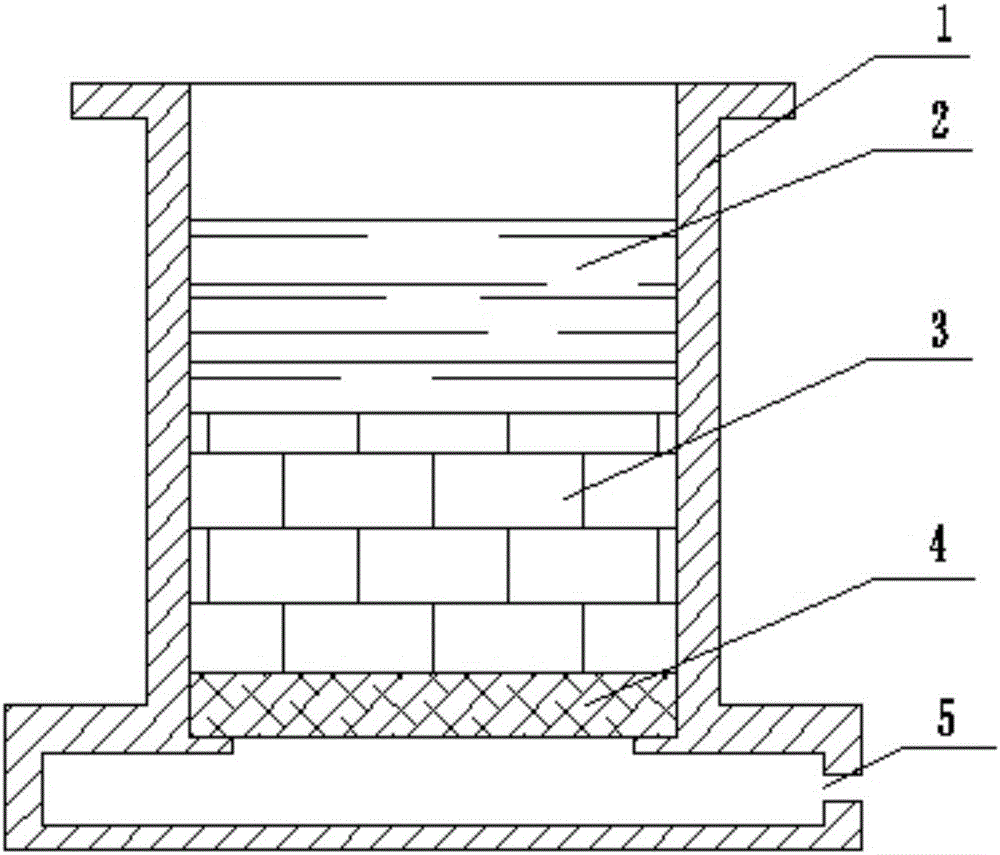

Image

Examples

Embodiment 1

[0047] A step, polyurethane sponge investment mold preparation

[0048] Select a three-dimensional polyurethane mesh sponge with a porosity of 97-98% and a pore diameter of 1.45-1.5mm with uniform pores and good connectivity. Put the prepared polyurethane sponge into the automatic spraying machine and adjust the machine to spray the polyurethane paint evenly to the surface of the polyurethane sponge; preheat the heating furnace to 55°C, then put the sprayed polyurethane sponge into the preheated heating furnace, raise the temperature to 110°C at a uniform speed, and keep it warm for 0.5h. Polyurethane sponge knots are not roughened.

[0049] Step B, preparation of plaster model

[0050] Put the polyurethane sponge prepared in step A into the mold, then proportion α-type hemihydrate gypsum according to the mass percentage, gypsum powder: retarder: inorganic binder: water=40:30:10:20, and Stir the gypsum slurry raw materials evenly until there are no air bubbles in the gypsum ...

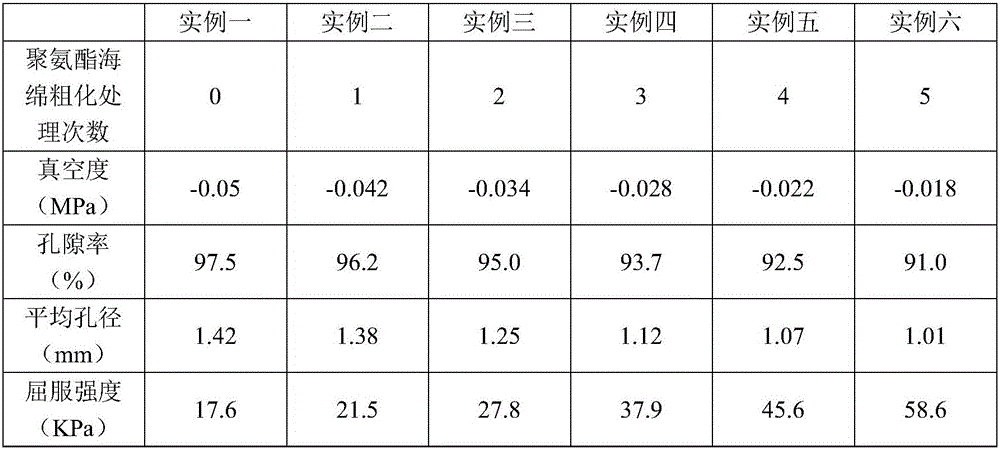

Embodiment 2

[0060] The polyurethane sponge knot was roughened once, and the rest of the steps and parameters were the same as in Example 1.

[0061] The parameters of the prepared through-hole foamed aluminum are as follows:

[0062] Porosity: 96.2%;

[0063] Average pore diameter: 1.38mm;

[0064] Yield strength: 21.5KPa.

Embodiment 3

[0066] A step, polyurethane sponge investment mold preparation

[0067] Select a three-dimensional polyurethane mesh sponge with a porosity of 97-98% and a pore diameter of 1.45-1.5mm with uniform pores and good connectivity. Put the prepared polyurethane sponge into the automatic spraying machine and adjust the machine to spray the polyurethane paint evenly to the surface of the polyurethane sponge; preheat the heating furnace to 57°C, then put the sprayed polyurethane sponge into the preheated heating furnace, raise the temperature to 115°C at a uniform speed, and keep it warm for 0.7h. The size and strength of the polyurethane structure that meets the requirements can be obtained by roughening the polyurethane sponge twice.

[0068] Step B, preparation of plaster model

[0069] Put the polyurethane sponge prepared in step A into the mold, and then proportion α-type hemihydrate gypsum according to the mass percentage, gypsum powder: retarder: inorganic binder: water=43:30:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com