Mass production technique of graphene

A production process and graphene technology, applied in the field of graphene, can solve the problems of reduced electrical conductivity and specific surface area of graphene, defects in carbon growth and connection, complicated graphene transfer process, etc. Structural defects, the effect of non-agglomeration of properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

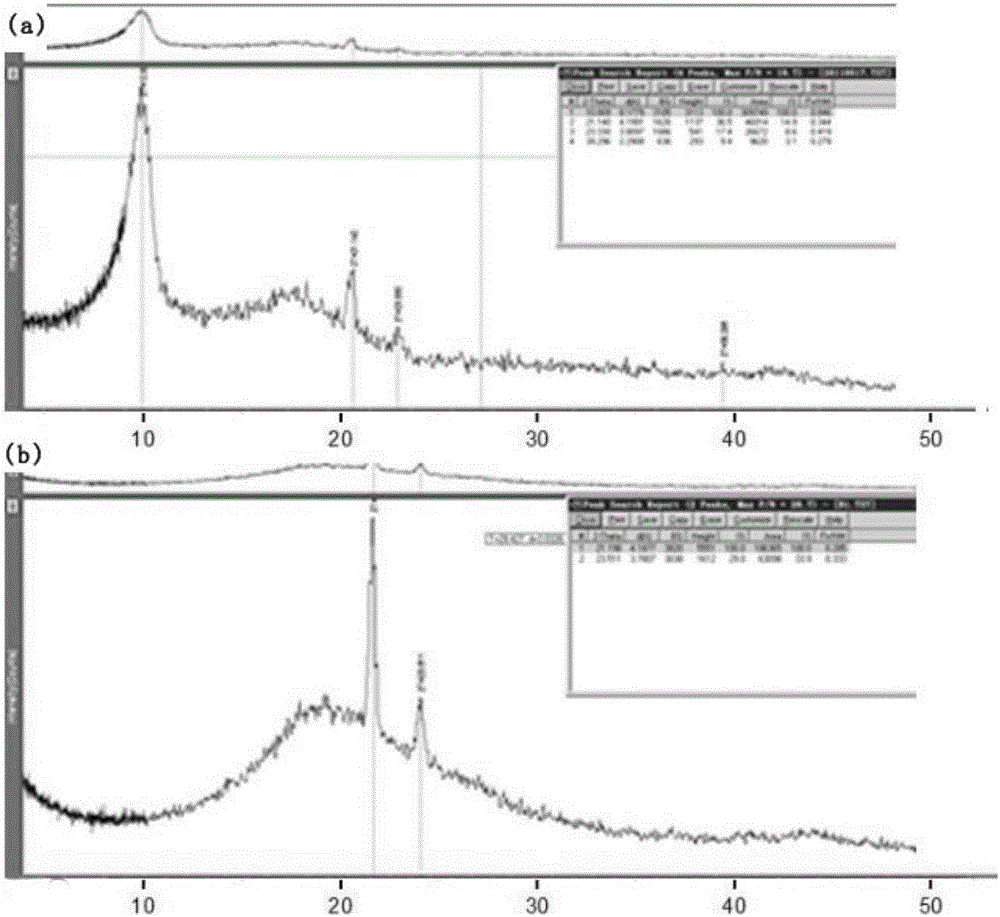

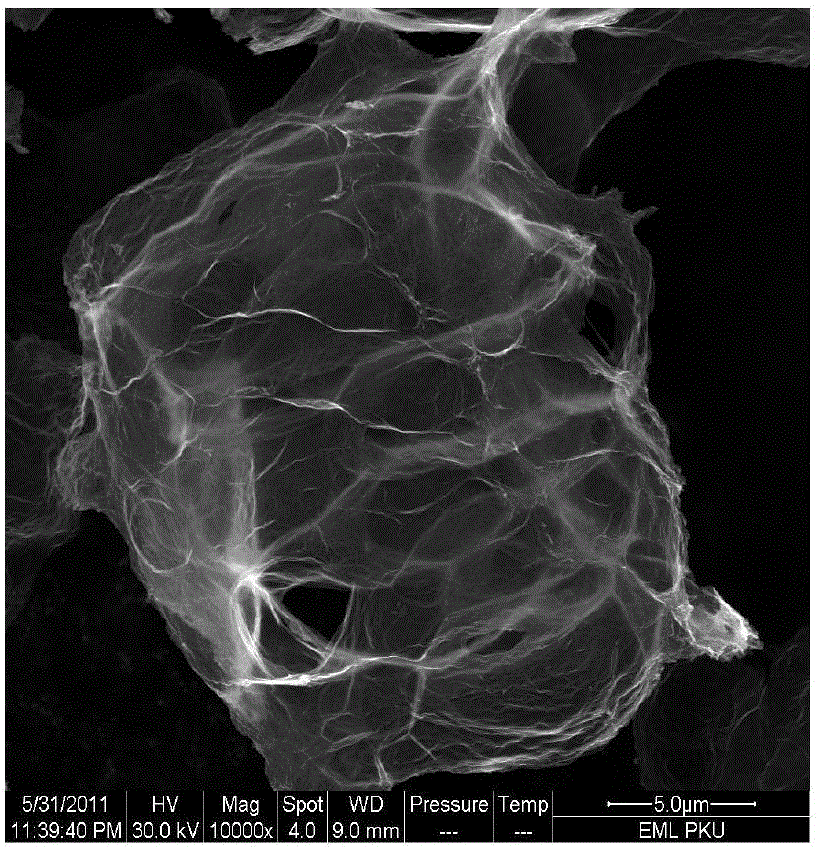

Image

Examples

Embodiment 1

[0054] The concentrated sulfuric acid with a mass concentration of 98% in the sulfuric acid storage tank is sent to the mixing tank through the No. 1 centrifugal pump and the high-level tank; graphite powder is added to the concentrated sulfuric acid in the mixing tank under stirring conditions, and after stirring evenly, the No. 2 centrifugal pump is sent into two oxidation kettles;

[0055] Add the concentrated sulfuric acid that weight concentration is 98% in 2 oxidation kettles, and add potassium permanganate in several times, carry out reaction, the material after the reaction finishes is sent into 2 via No. 3 centrifugal pump, cache kettle, No. 4 centrifugal pump. a quenching tank;

[0056] Add hydrogen peroxide to the two quenching kettles to carry out the quenching reaction. After the reaction, the material is sent into the osmosis kettle by the No. 12 centrifugal pump, and deionized water is injected into the osmosis kettle. Washing, the washed material is sent to th...

Embodiment 2

[0064] The concentrated sulfuric acid with a mass concentration of 98% in the sulfuric acid storage tank is sent to the mixing tank through the No. 1 centrifugal pump and the high-level tank; graphite powder is added to the concentrated sulfuric acid in the mixing tank under stirring conditions, and after stirring evenly, the No. 2 centrifugal pump is sent into two oxidation kettles;

[0065] Add the concentrated sulfuric acid that weight concentration is 98% in 2 oxidation kettles, and add potassium permanganate in several times, carry out reaction, the material after the reaction finishes is sent into 2 via No. 3 centrifugal pump, cache kettle, No. 4 centrifugal pump. a quenching tank;

[0066] Add hydrogen peroxide to the 2 quenching kettles to carry out the quenching reaction. The material after the reaction is sent to 5 sedimentation kettles by the No. 13 centrifugal pump, and deionized water is added to the 5 sedimentation kettles for sedimentation. The material enters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com