Falling water oxygen-enriched micro-aerobic sludge bed process and its wastewater treatment method

A sludge bed, oxygen-enriched technology, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, biological water/sewage treatment, etc., can solve the problem of insufficient treatment technology, high treatment cost, and infrastructure investment Large problems, to achieve the effect of good physical and chemical structure and settlement performance, low treatment cost and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

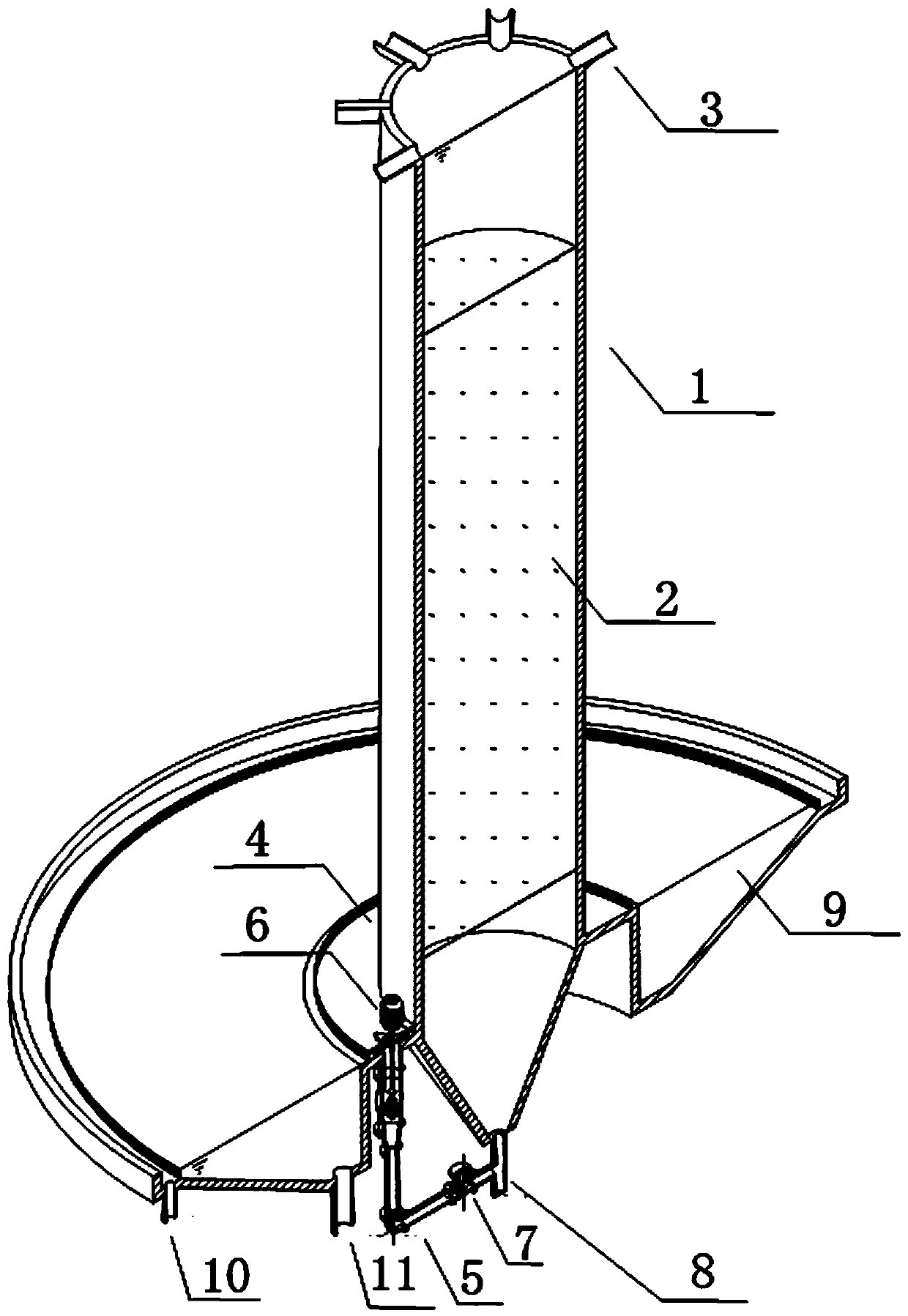

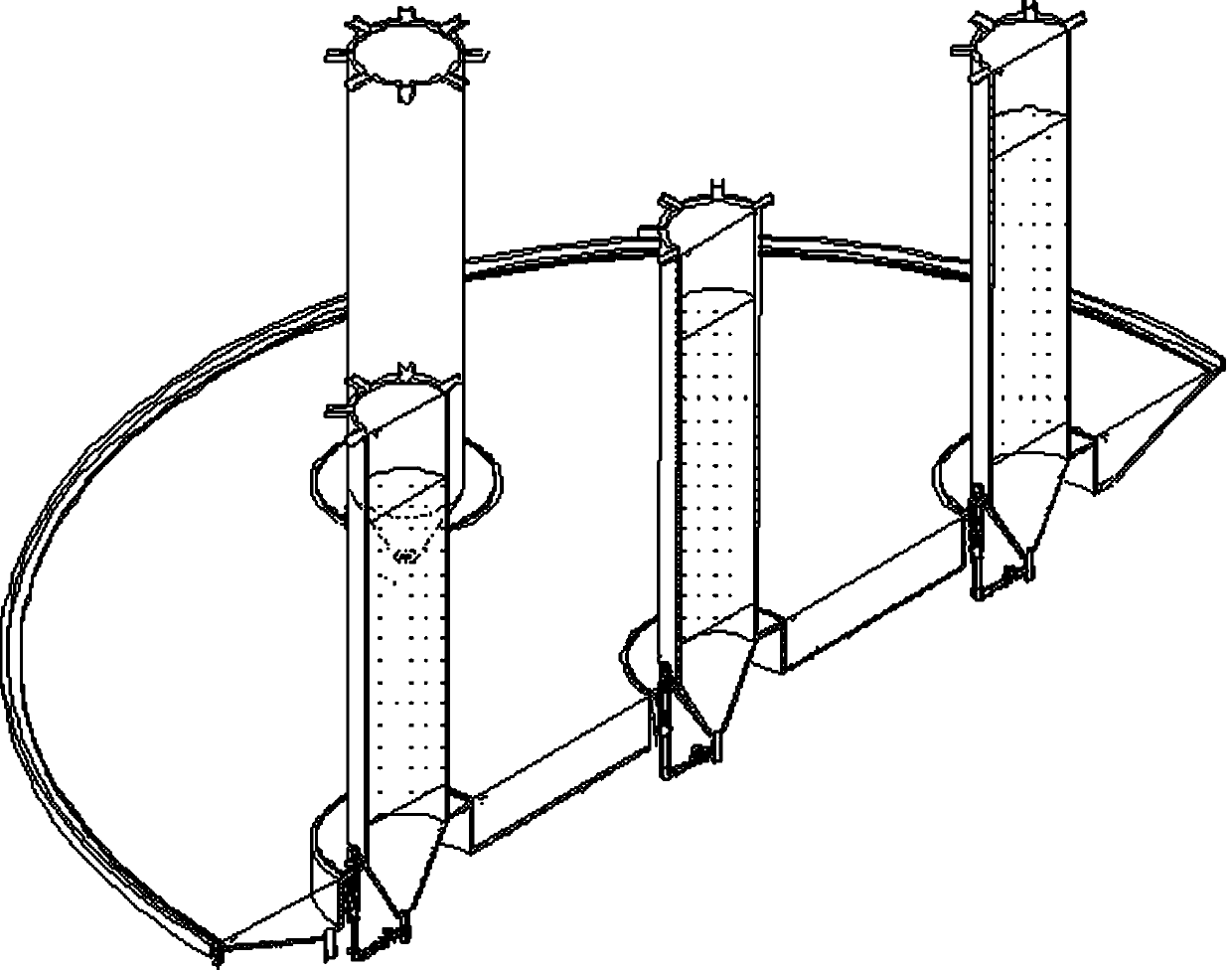

[0023] to combine figure 1 and 2 Description of this embodiment, the falling water oxygen-enriched micro-oxygen sludge bed process in this embodiment consists of a micro-oxygen sludge bed 1, a filler 2, a water drop drainage tank 3, an oxygen-enriched mud water return pool 4, an oxygen-enriched mud water return pipe 5, and a return Pump 6, check valve 7, micro-oxygen sludge bed inlet pipe 8, sedimentation tank 9, sedimentation tank outlet pipe 10 and excess sludge discharge pipe 11; the micro-oxygen sludge bed 1, filler 2, drop water drainage Groove 3, oxygen-enriched mud water return pool 4, oxygen-enriched mud water return pipe 5, return pump 6, check valve 7, micro-oxygen sludge bed water inlet pipe 8 constitute a treatment unit; the treatment unit is placed in the sedimentation tank 9, One or more treatment units can be set in the same settling tank 9; the micro-aerobic sludge bed 1 is arranged in a vertical columnar shape with an open top, and a filler 2 is provided insi...

Embodiment 1

[0029] Example 1: Combining figure 1 Illustrate present embodiment, the specific method that present embodiment utilizes the described device of specific embodiment to process low C / N ratio waste water is as follows:

[0030]Wastewater with low C / N ratio enters it from the bottom of microaerobic sludge bed 1 through the microaerobic sludge bed inlet pipe 8, and the pollutants in the wastewater are treated by the microaerobic bacteria in the filler layer 2, and the treated wastewater is discharged from the microaerobic sludge bed. The falling water drainage tank 3 on the top of the sludge bed 1 naturally falls to the oxygen-enriched mud water return pool 4 to realize the oxygen-enrichment process. The mud bed 1 provides oxygen for the microaerobic bacteria in it, the reflux ratio is 20:1, and the hydraulic retention time is 15h; the excess oxygen-enriched wastewater overflows into the sedimentation tank 9, and then overflows through the sedimentation tank 9, and is discharged f...

Embodiment 2

[0034] Embodiment 2: Combination figure 1 Illustrate present embodiment, the specific method that present embodiment utilizes the described device of specific embodiment to process general C / N ratio waste water is as follows:

[0035] Generally, the C / N ratio wastewater enters from the bottom of the microaerobic sludge bed 1 through the microaerobic sludge bed inlet pipe 8, and the pollutants in the wastewater are treated by the microaerobic bacteria group in the filler layer 2, and the treated wastewater is discharged from the microaerobic sludge bed. The falling water drainage tank 3 on the top of the sludge bed 1 naturally falls to the oxygen-enriched mud water return pool 4 to realize the oxygen-enrichment process. The mud bed 1 provides oxygen for the microaerobic bacteria in it, the reflux ratio is 30:1, and the hydraulic retention time is 12h; the excess oxygen-enriched wastewater overflows into the sedimentation tank 9, and then overflows through the sedimentation tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com