High temperature resistant wall material produced by using waste glass particles and preparation method thereof

A technology of wall materials and waste glass, which is applied in the field of high-temperature-resistant wall materials, can solve the problems of low high-temperature resistance, high price of wall materials, and poor high-temperature resistance, and achieve low production costs, excellent thermal insulation performance, and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of slag, calcium carbide slag and ceramsite high-strength wall insulation material, its preparation method has the following steps:

[0044] (1) Pretreatment of waste glass particles

[0045] According to the requirements of GB / T 14681-2011, 4.75mm, 2.36mm, 1.18mm, 600μm, 300μm, and 150μm square hole sieves are used for sieve analysis, and the fineness modulus (M x ) in the range of 2.3 to 3.0, the cumulative sieve percentage (A 1 ~A 6 ) are in Zone II, with good gradation.

[0046] (2) Raw material weighing

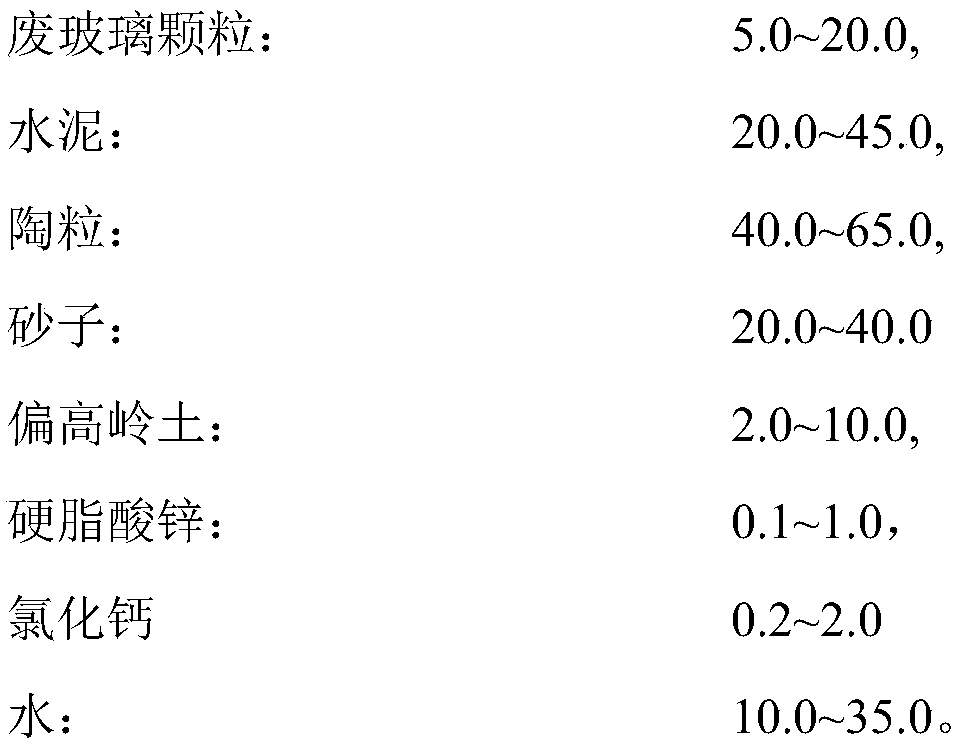

[0047] In parts by mass, prepared pretreated waste glass particles 5.0-20.0, cement 20.0-45.0, ceramsite 40.0-65.0, sand 20.0-40.0, metakaolin 2.0-10.0, zinc stearate 0.1-1.0, calcium chloride 0.2~2.0.

[0048] (3) dry mix

[0049] Put the above-mentioned weighed raw materials into a vertical mixer at a speed of 40r / min, and mechanically stir for 1-2min.

[0050] (4) Add water and stir

[0051] Add 10.0-35.0% of water to the above-mentioned stirred ...

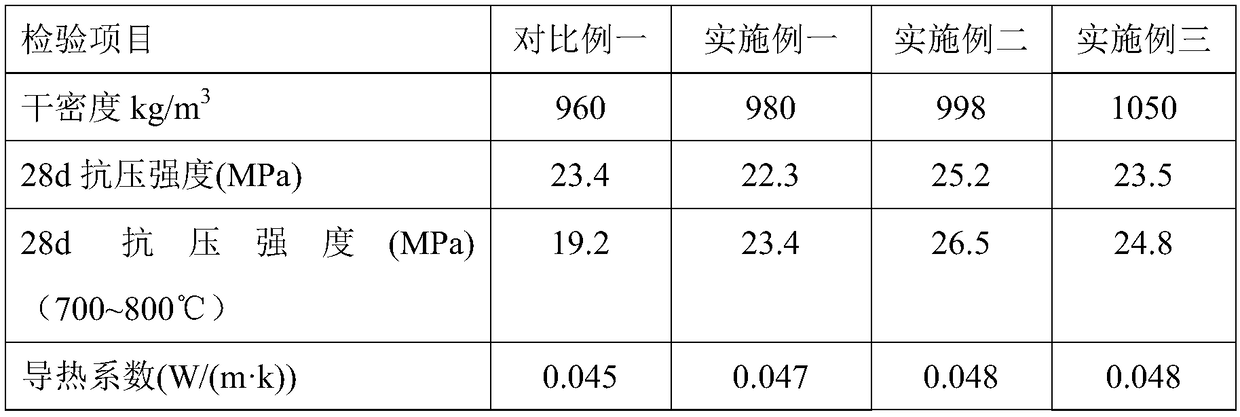

Embodiment 1

[0059] A research and preparation method of using waste glass to produce high-temperature-resistant wall materials, the preparation method has the following steps:

[0060] (1) Pretreatment of waste glass particles

[0061] According to the requirements of GB / T 14681-2011, 4.75mm, 2.36mm, 1.18mm, 600μm, 300μm, and 150μm square hole sieves are used for sieve analysis, and the fineness modulus (M x ) in the range of 2.3 to 3.0, the cumulative sieve percentage (A 1 ~A 6 ) are in Zone II, with good gradation.

[0062] (2) Raw material weighing

[0063] In parts by mass, the prepared pretreated waste glass particles are 15, cement 25, ceramsite 45, sand 35, metakaolin 4.0, zinc stearate 0.5, and calcium chloride 1.2.

[0064] (3) dry mix

[0065] Put the above-mentioned weighed raw materials into a vertical mixer at a speed of 40r / min, and mechanically stir for 1.5min.

[0066] (4) Add water and stir

[0067] Add water 16 to the above-mentioned stirred dry material (by mass ...

Embodiment 2

[0073] A research and preparation method of using waste glass to produce high-temperature-resistant wall materials, the preparation method has the following steps:

[0074] (1) Pretreatment of waste glass particles

[0075] According to the requirements of GB / T 14681-2011, 4.75mm, 2.36mm, 1.18mm, 600μm, 300μm, and 150μm square hole sieves are used for sieve analysis, and the fineness modulus (M x ) in the range of 2.3 to 3.0, the cumulative sieve percentage (A 1 ~A 6 ) are in Zone II, with good gradation.

[0076] (2) Raw material weighing

[0077] In parts by mass, 10 pretreated waste glass particles, 30 cement, 50 ceramsite, 25 sand, 3.5 metakaolin, 0.4 zinc stearate, and 1.0 calcium chloride are prepared.

[0078] (3) dry mix

[0079] Put the above-mentioned weighed raw materials into a vertical mixer at a speed of 40r / min, and mechanically stir for 1.5min.

[0080] (4) Add water and stir

[0081] Add water 18 to the above-mentioned stirred dry material (by mass part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com