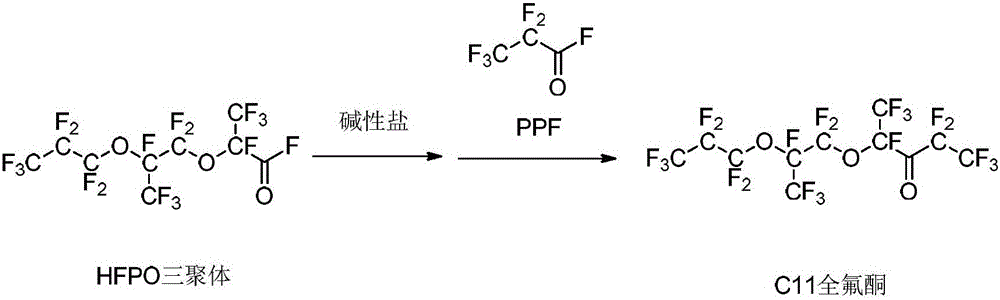

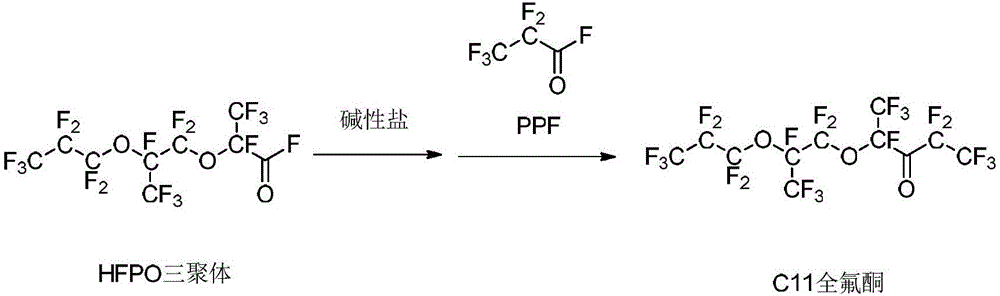

Method for preparing C11 perfluoroketone

A technology of perfluoroketone and perfluoropropionyl fluoride, which is applied in the field of preparing C11 perfluoroketone, can solve problems such as difficulties and increased production costs, and achieve the effects of short reaction time, fast reaction speed and convenient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, a method for preparing C11 perfluoroketone, the specific steps of the preparation method are as follows: 144g of hexafluoropropylene oxide trimer, potassium carbonate (44g) and diglyme (260mL) were added to 1L In the reaction kettle, stirred and reacted at 0°C for 2 hours, then introduced PPF (62g), raised the temperature to 95°C, stirred and reacted for 2 hours, observed that the reaction pressure did not change, lowered the temperature, opened the reaction kettle, separated the lower layer liquid and distilled to obtain The yield of product C11 perfluoroketone (149g) was 86%.

Embodiment 2

[0014] Embodiment 2, a kind of method for preparing C11 perfluoroketone, the concrete steps of preparation method are as follows: Hexafluoropropylene oxide trimer (1000g), cesium carbonate (687g) and acetonitrile (2.6L) are added in 10L reactor , stirred and reacted at 0°C for 2 hours, then introduced PPF (417g), raised the temperature to 115°C, stirred and reacted for 3 hours, observed that the reaction pressure did not change, lowered the temperature, opened the reaction kettle, separated the lower layer and distilled to obtain the product C11 Fluoroketone (1069g), yield 89%.

[0015] The invention simplifies the environmental protection treatment process, the raw materials are easy to obtain, the reaction yield is improved, the operation is simple, the purification is easy, and the scale-up production can be carried out. Hexafluoropropylene oxide trimer, perfluoropropionyl fluoride (PPF) As the starting reactant, the final product is obtained through one-step reaction, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com