Silane modified polyether sealant and preparation method thereof

A silane-modified polyether and sealant technology, applied in the direction of polyether adhesives, adhesives, adhesive types, etc. The effect of adhesion, broadening the scope of application, and quick follow-up repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

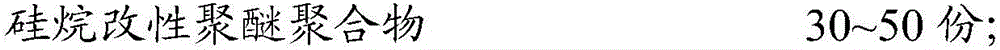

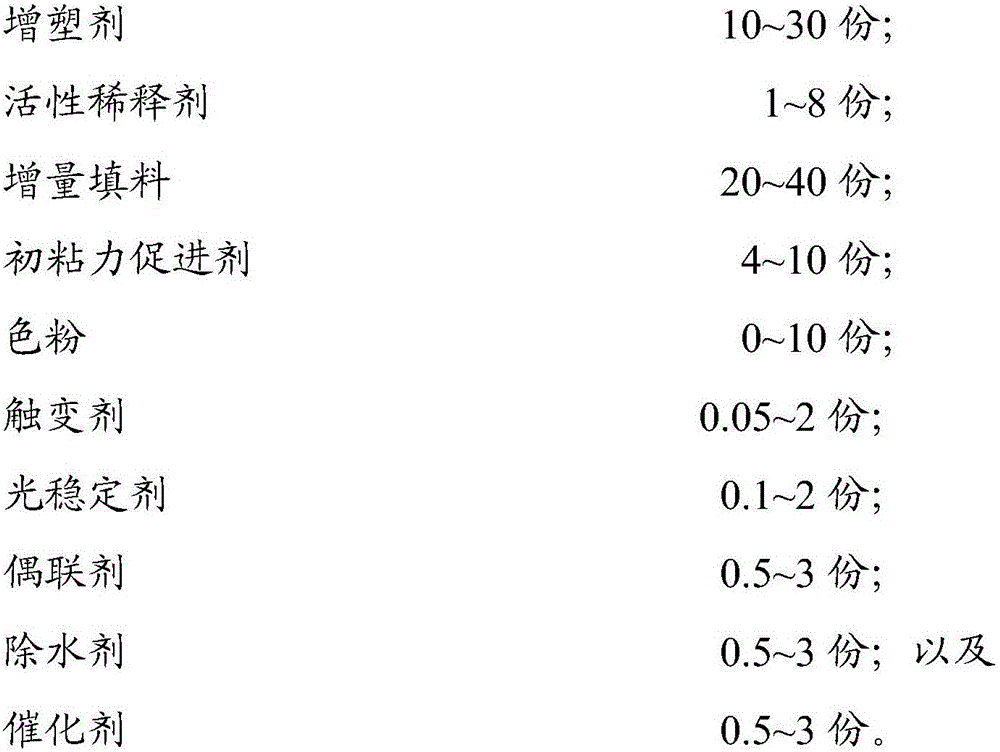

[0035] A silane-modified polyether sealant with high initial tack, its raw materials and parts by weight: 30 parts of silane-modified polyether polymer, 10 parts of plasticizer polyether polyol PPG3000, reactive diluent CH 3 (C 2 h 5 O) 2 -Si-(CH 2 O) 3 -C 2 h 5 8 parts, 40 parts of nano-active calcium carbonate for extender filler, 5 parts of liquid rosin resin, 10 parts of titanium dioxide, 0.05 part of polyamide wax, 0.5 part of light stabilizer BASF 326 and 0.5 part of BASF 770, coupling agent N-aminoethyl 1.5 parts of base-γ-aminopropyltrimethoxysilane, 2 parts of vinyltrimethoxysilane as a dehydrating agent, and 0.5 parts of dibutyltin diacetylacetonate as a catalyst.

[0036] Wherein, the silane-modified polyether polymer structure is as follows:

[0037]

[0038] And the viscosity is 60 Pa·s.

[0039] The preparation method of the silane-modified polyether sealant of above-mentioned high initial tack comprises the following steps:

[0040] Mix silane-modifi...

Embodiment 2

[0042] A kind of silane-modified polyether sealant of high initial tack, its raw material and parts by weight are composed of: 50 parts of silane-modified polyether polymer, 30 parts of plasticizer DIDP, reactive diluent (CH 3 O) 3 -Si-CH 2 O-CH 3 1 part, 20 parts of nano-active calcium carbonate for extender filler and 10 parts of heavy calcium carbonate, 10 parts of initial adhesion promoter terpene resin, 1 part of carbon black, 2 parts of thixotropic organic bentonite, light stabilizer BASF 245 0.1 0.25 parts of coupling agent γ-aminopropyl triethoxysilane and 0.25 parts of isocyanatopropyl triethoxysilane, 3 parts of water removing agent γ-mercaptopropyl trimethoxysilane, catalyst dilauric acid di 3 parts of butyl tin.

[0043] The structure of the silane-modified polyether polymer is as follows:

[0044]

[0045] And the viscosity is 1Pa·s.

[0046] The preparation method of the silane-modified polyether sealant of above-mentioned high initial tack comprises the...

Embodiment 3

[0049]A kind of silane-modified polyether sealant of high initial tack, its raw material and parts by weight are composed of: 40 parts of silane-modified polyether polymer, 25 parts of plasticizer DINP, reactive diluent (CH 3 O) 3 -Si-(CH 2 O) 2 -C 2 h 5 4 parts, 15 parts of filler silica powder and 10 parts of kaolin, 3 parts of liquid rosin resin and 2 parts of terpene resin, 6 parts of titanium dioxide, 1 part of carbon black, 0.5 part of thixotropic agent hydrogenated castor oil And 1 part of polyamide wax, 1 part of light stabilizer BASF UV-9 and 1 part of BASF 540, 3 parts of coupling agent γ-aminopropyl triethoxysilane, water remover 3-isocyanatopropyl trimethoxy 1 part of silane, 0.5 part of vinyltrimethoxysilane, 1 part of catalyst stannous octoate and 1 part of dibutyltin diacetylacetonate.

[0050] The structure of the silane-modified polyether polymer is as follows:

[0051]

[0052] And the viscosity is 10 Pa·s.

[0053] The preparation method of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com