Method and device for utilizing scheelite concentrate smelting slag and application of scheelite concentrate smelting slag

A technology of scheelite and mixing device, which is applied in the petroleum industry, solid fuel, fuel, etc., to achieve the effect of reducing production cost, reducing difficulty, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

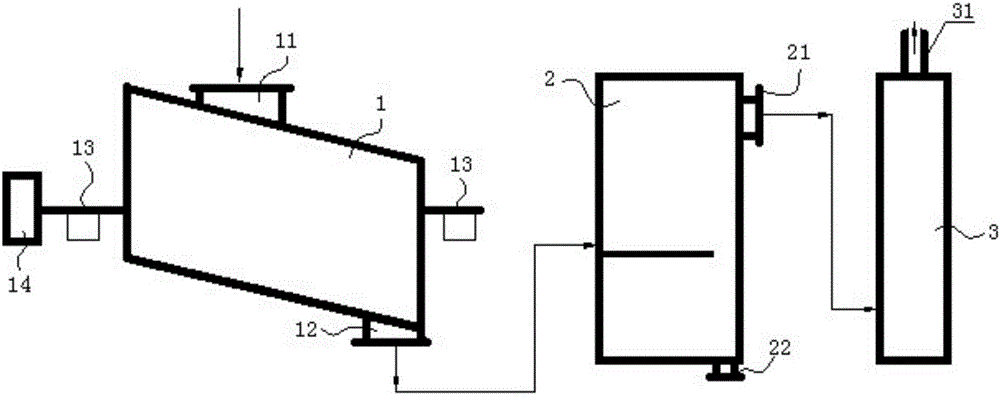

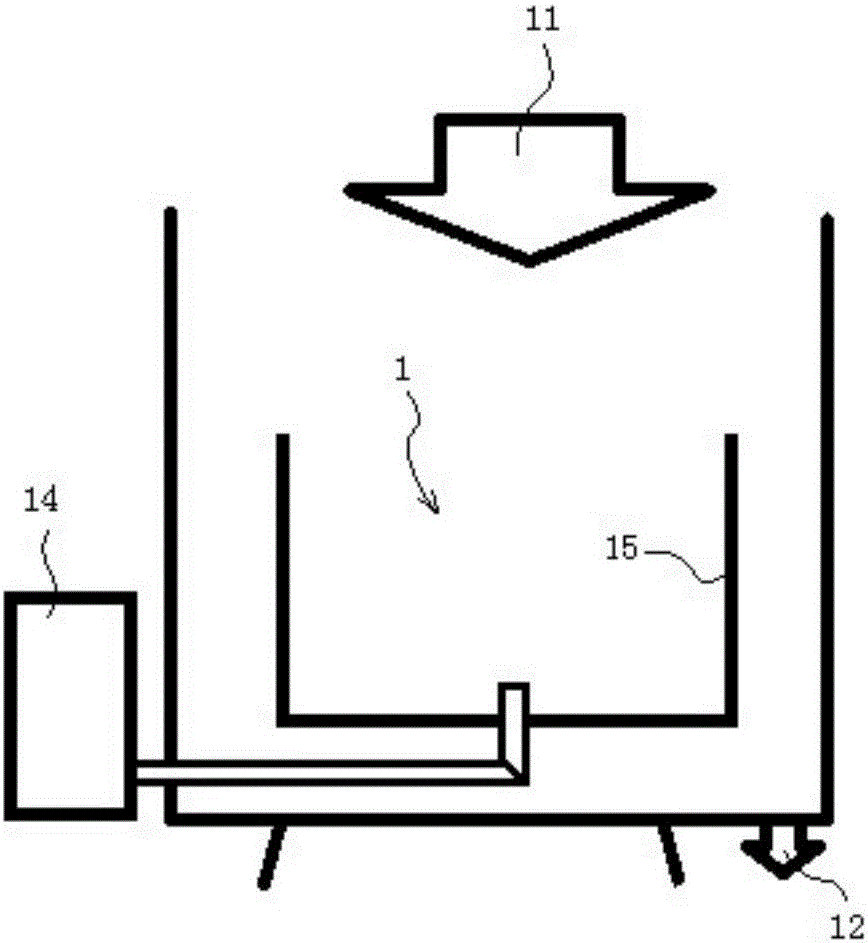

[0039] Scheelite slag and coal enter the mixing device 1 from the feeding device 11, close the feeding device 11, start the transmission device 14, the mixing material rotates with the transmission shaft 13, and after the materials in the mixing device 1 are mixed evenly, open the outlet The material device 12 sends the mixed materials into the combustion device 2 for combustion, the slag is discharged from the slag discharge device 22, and the tail gas is discharged from the tail gas discharge device 21 into the tail gas treatment device 3.

[0040] In another embodiment, scheelite slag and coal are added from the feeding device 11, the transmission device 14 is started, the anchor stirring device 15 rotates in the mixing device 1, and the materials in the mixing device 1 are driven to stir together, thereby achieve the purpose of mixing. After mixing evenly, the material is discharged from the discharge device 12 and enters the combustion device 2.

[0041] In the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com