Preparation method of compound enzyme preparation for efficiently degrading aflatoxin B1

A compound enzyme preparation, aflatoxin technology, applied in the fields of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of little research, achieve significant material saving, high efficiency, and improve the effect of degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Fermentation and culture of Neurospora palpus and Penicillium raceae, and centrifugation of the respective culture solutions in centrifuge tubes at 5500rpm for 10 minutes, separating the supernatant from the lower layer of bacteria, concentrating the supernatant by ultrafiltration 10 times, using 50 % saturated ammonium sulfate precipitation, centrifuged at 10,000 rpm for 5 minutes, discarded the supernatant, redissolved the precipitated protein in phosphate buffer, dialyzed overnight and then freeze-dried, and then used the obtained protein as the crude enzyme preparation of N. Penicillium penicillium crude enzyme preparation, save for future use.

[0029]Mix the crude enzyme preparation of Neurospora aerugaus, the crude enzyme preparation of Penicillium raceae, and the fungal laccase respectively in component percentages (20%, 20%, 60%), and weigh 0.2g of the compound enzyme preparation (which contains 0.04g Crude enzyme preparation from Neurospora californica, 0.04g ...

Embodiment 2

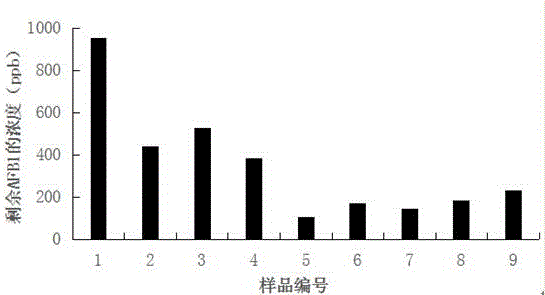

[0032] On the basis of the preparation of the crude enzyme preparations of Neuromonas aeruginosa and the crude enzyme preparations of Penicillium raceae in Example 1, the crude enzyme preparations of Neuromonas arborescens, the crude enzyme preparations of Penicillium raceus and fungal laccase were respectively divided into components Percentages (40%, 40%, 20%) were mixed to make a compound enzyme preparation, and weighed 0.4g compound enzyme preparation (including 0.16g of N. fungal laccase), fully shaken and dissolved in 1L sterile distilled water to make an enzyme solution, so that the concentration in the system is 0.4g / L, adding aflatoxin B1 standard product to make the initial concentration of aflatoxin B1 in the enzyme solution is 1ppm. At this time, the ratio of the compound enzyme preparation to the aflatoxin B1 in the degradation system was 0.4 g / L·ppm. Control the culture temperature at 36°C, pH at 6.5, and detect the degradation time required when the remaining c...

Embodiment 3

[0035] On the basis of the preparation of the crude enzyme preparations of Neuromonas aeruginosa and the crude enzyme preparations of Penicillium raceae in Example 1, the crude enzyme preparations of Neuromonas arborescens, the crude enzyme preparations of Penicillium raceus and fungal laccase were respectively divided into components Percentage (40%, 40%, 20%), weigh 0.4g compound enzyme preparation (including 0.16g crude enzyme preparation of Neuromonas aerulus, 0.16g crude enzyme preparation of Penicillium laceii, 0.08g fungal laccase), Dissolve in 1L sterile distilled water with sufficient shaking to make an enzyme solution, so that the concentration in the system is 0.4g / L, and add aflatoxin B1 standard substance to make the initial concentration of aflatoxin B1 in the enzyme solution 1ppm. The content of the initial aflatoxin B1 was detected as a control. At this time, the ratio of the compound enzyme preparation to the aflatoxin B1 in the degradation system was 0.4 g / L·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com