Method for recycling uranium from acidic waste water containing ammonium nitrate and uranium

A recovery method and ammonium nitrate technology are applied in the field of uranium-containing wastewater treatment and can solve problems such as inability to meet demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

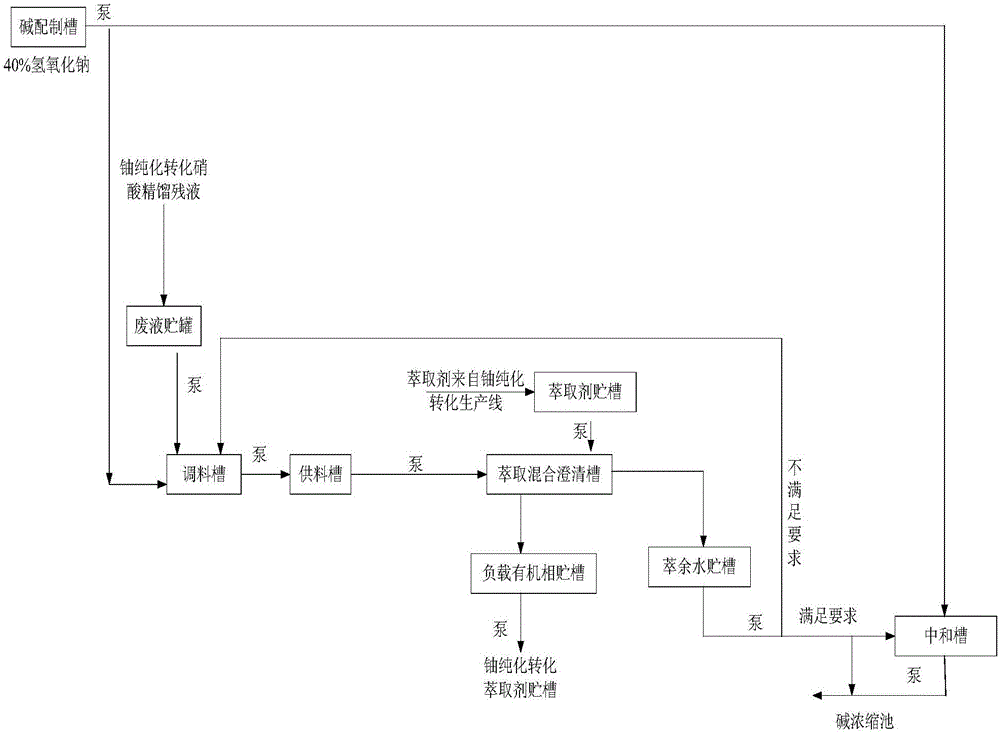

[0034] Such as figure 1 Described, a kind of method for recovering uranium in acidic ammonium nitrate-containing uranium-containing wastewater of the present invention, it comprises the steps:

[0035] (1) The acidic ammonium nitrate-containing uranium-containing wastewater from uranium purification and conversion is mixed with sodium hydroxide solution to form an extraction stock solution with an acidity of 0.5mol / L;

[0036] The components of the acidic ammonium nitrate-containing uranium-containing wastewater include: [U]=4g / L, [HNO 3 ]=3mol / L, [NH 4 NO 3 ]=500g / L;

[0037] The mass percentage of described sodium hydroxide solution is 40%;

[0038] (2) extract the stock solution of step (1) gained and the TBP-hydrogenated kerosene extractant (30% tributyl phosphate+70% hydrogenated kerosene) of 30% by volume percentage to extract; Phase flow ratio 1:4;

[0039] (3) After the extraction, the loaded organic phase can be sent to the uranium purification conversion extrac...

Embodiment 2

[0041] Such as figure 1 Shown, the recovery method of uranium in a kind of acidic ammonium nitrate-containing uranium-containing wastewater of the present invention, it comprises the steps:

[0042] (1) The acidic ammonium nitrate-containing uranium-containing wastewater from uranium purification and conversion is pumped to the waste liquid storage tank for temporary storage;

[0043] The components of the acidic ammonium nitrate-containing uranium-containing wastewater include: [U]=4g / L, [HNO 3 ]=3mol / L, [NH 4 NO 3 ]=500g / L;

[0044] (2) When the wastewater described in step (1) is treated, it is pumped into the seasoning tank;

[0045] (3) use solid sodium hydroxide and deionized water preparation mass percent in the alkali preparation tank to be 40% sodium hydroxide solution, this sodium hydroxide solution is also pumped in the seasoning tank, and step (2) described The waste water is prepared into an extraction stock solution with an acidity of 0.5mol / L;

[0046] (4)...

Embodiment 3

[0052] Such as figure 1 Described, a kind of method for recovering uranium in acidic ammonium nitrate-containing uranium-containing wastewater of the present invention, it comprises the steps:

[0053] (1) The acidic ammonium nitrate-containing uranium-containing wastewater from uranium purification and conversion is mixed with sodium hydroxide solution to form an extraction stock solution with an acidity of 0.5mol / L;

[0054] The components of the acidic ammonium nitrate-containing uranium-containing wastewater include: [U]=0.2g / L, [HNO 3 ]=0.5mol / L, [NH 4 NO 3 ]=100g / L;

[0055] The mass percentage of described sodium hydroxide solution is 30%;

[0056] (2) extracting the stock solution obtained in step (1) with a TBP-hydrogenated kerosene extractant with a volume percentage of 20%; the two-phase flow ratio of the extractant and the stock solution is 1:3;

[0057] (3) After the extraction, the loaded organic phase can be sent to the uranium purification conversion extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com