Manufacture method for twin pole device resisting low dosage rate irradiation

A bipolar device, low dose rate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. With radiation resistance and other issues, to achieve the effect of reducing the total number of defects, small stress and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

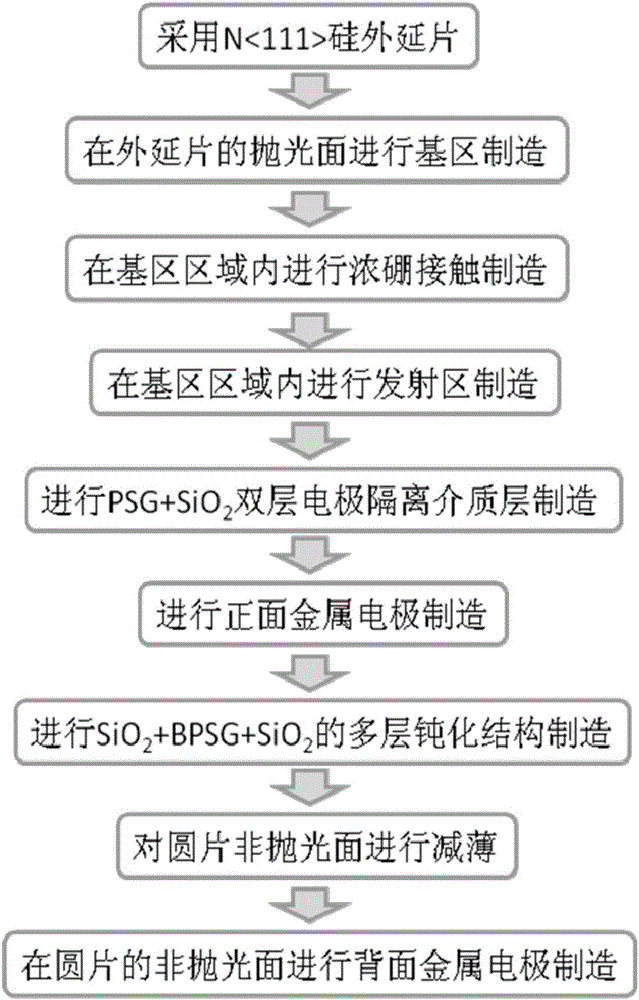

Method used

Image

Examples

Embodiment

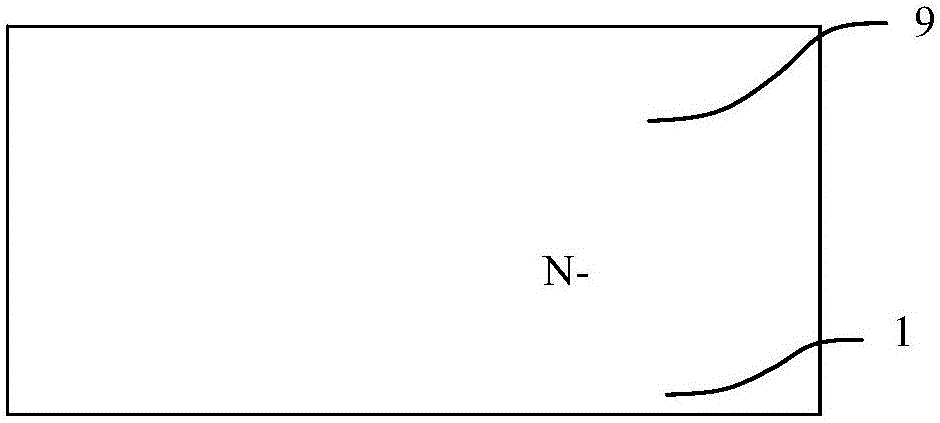

[0057] (1) Material selection: such as figure 2 , select the N-type silicon epitaxial wafer 1 with crystal orientation as the substrate material, the total thickness of the silicon wafer is 525μm, the N-type epitaxial thickness is 50um, and the doping concentration is 2e14cm -3 .

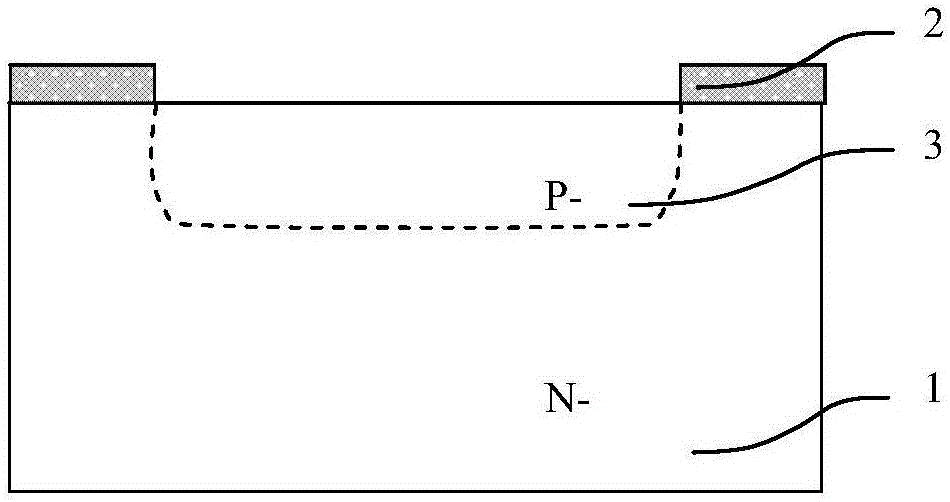

[0058] (2) Base manufacturing: such as image 3 , using silicon N-type epitaxial wafer 1 as the base material, depositing Oxide layer 2. Then perform photolithography on the base of the triode, and then use a wet etching process to expose the injection window in the base area, with a dose of 1e14cm -2 Boron implantation in the base area, and then oxidize the boron-injected N-type epitaxial wafer at a temperature of 1200°C for 100 minutes. forming a P-type transistor base region 3 on the polished surface of the N-type epitaxial wafer;

[0059] (3) Concentrated boron contact: such as Figure 4 , in the area of the base region 3 of the triode, photolithography concentrated boron pattern, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com