Carbon quantum dot enhanced photoelectric detector and preparation method thereof

A technology of photodetectors and carbon quantum dots, applied in the field of photodetectors, can solve problems that have not been found and reported, and achieve the effects of simple preparation process, easy promotion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

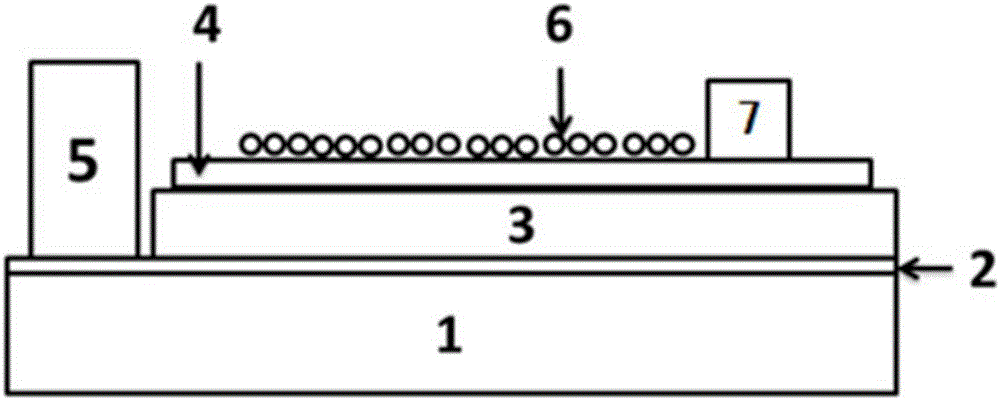

Embodiment 1

[0022] 1) Clean the polyimide flexible substrate in deionized water and dry it;

[0023] 2) Using magnetron sputtering to deposit 40 nanometers of indium-doped germanium on a polyimide flexible substrate;

[0024] 3) Depositing a 6-micron-thick germanium tin layer on the indium-doped germanium tin layer by physical vapor deposition technology, and reserving an area for growing the first electrode on the ITO layer;

[0025] 4) Depositing germanium silicide on the germanium tin layer;

[0026] 5) spin coating the carbon quantum dot solution on the germanium silicide, and reserve an area for growing the second electrode on the germanium silicide; the diameter of the carbon quantum dot is 1nm-1μm;

[0027] 6) Coating silver paste on the reserved area of germanium silicide and the reserved area on the ITO layer and drying; obtaining a germanium silicide / germanium tin oxide photodetector enhanced by carbon quantum dots.

Embodiment 2

[0029] 1) Clean the glass substrate in deionized water and dry it;

[0030] 2) Deposit 200 nanometer thick fluorine-doped germanium tin oxide on the glass substrate by magnetron sputtering;

[0031] 3) Depositing an 8 micron-thick germanium tin layer on the fluorine-doped germanium tin layer by physical vapor deposition technology, and reserving an area for growing the first electrode on the FTO layer;

[0032] 4) Depositing germanium silicide on the germanium tin layer;

[0033] 5) Spraying a carbon quantum dot solution on the germanium silicide, and reserving an area for growing the second electrode on the germanium silicide layer; the diameter of the carbon quantum dot is 1nm-1μm;

[0034] 6) thermally evaporating gold electrodes at the reserved area of the germanium silicide layer and the reserved area on the fluorine-doped germanium tin oxide layer; obtaining a germanium silicon oxide / germanium tin oxide photodetector enhanced by carbon quantum dots.

Embodiment 3

[0036] 1) Clean the ceramic substrate in deionized water and dry it;

[0037] 2) Electron beam evaporation is used to deposit nickel metal with a thickness of 60 nanometers on the ceramic substrate;

[0038] 3) Depositing a germanium tin oxide layer with a thickness of 5 microns on the nickel metal layer by chemical water bath method, and reserving an area for growing the first electrode on the nickel metal layer;

[0039] 4) Depositing germanium silicide on the germanium tin layer;

[0040] 5) preparing a carbon quantum dot film on the germanium silicide layer, and reserving an area for growing the second electrode on the germanium silicide layer;

[0041] 6) screen-print silver electrodes on the reserved area of the germanium silicide layer and the reserved area on the nickel metal layer; obtain a germanium silicide / germanium tin oxide photodetector enhanced by carbon quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com