Anti-biological fouling reverse osmosis membrane and preparation method thereof

A technology of anti-biological pollution and reverse osmosis membrane, which is applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of toxicity, unfriendly human body and environment, anti-biological pollution, etc., and achieve the purpose of inhibiting growth and raw materials Convenient source and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

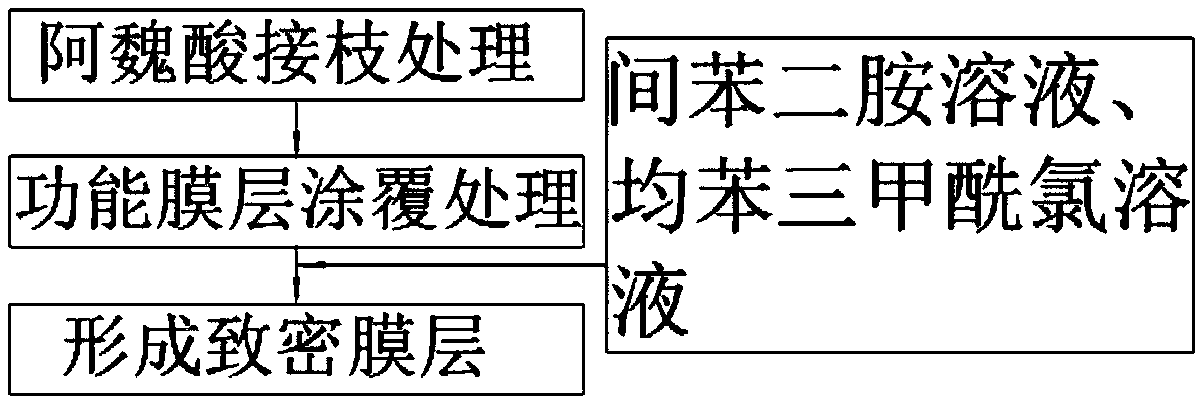

[0031] Such as figure 1 As shown, in a specific embodiment, the preparation method of the anti-biological pollution reverse osmosis membrane includes at least the following steps:

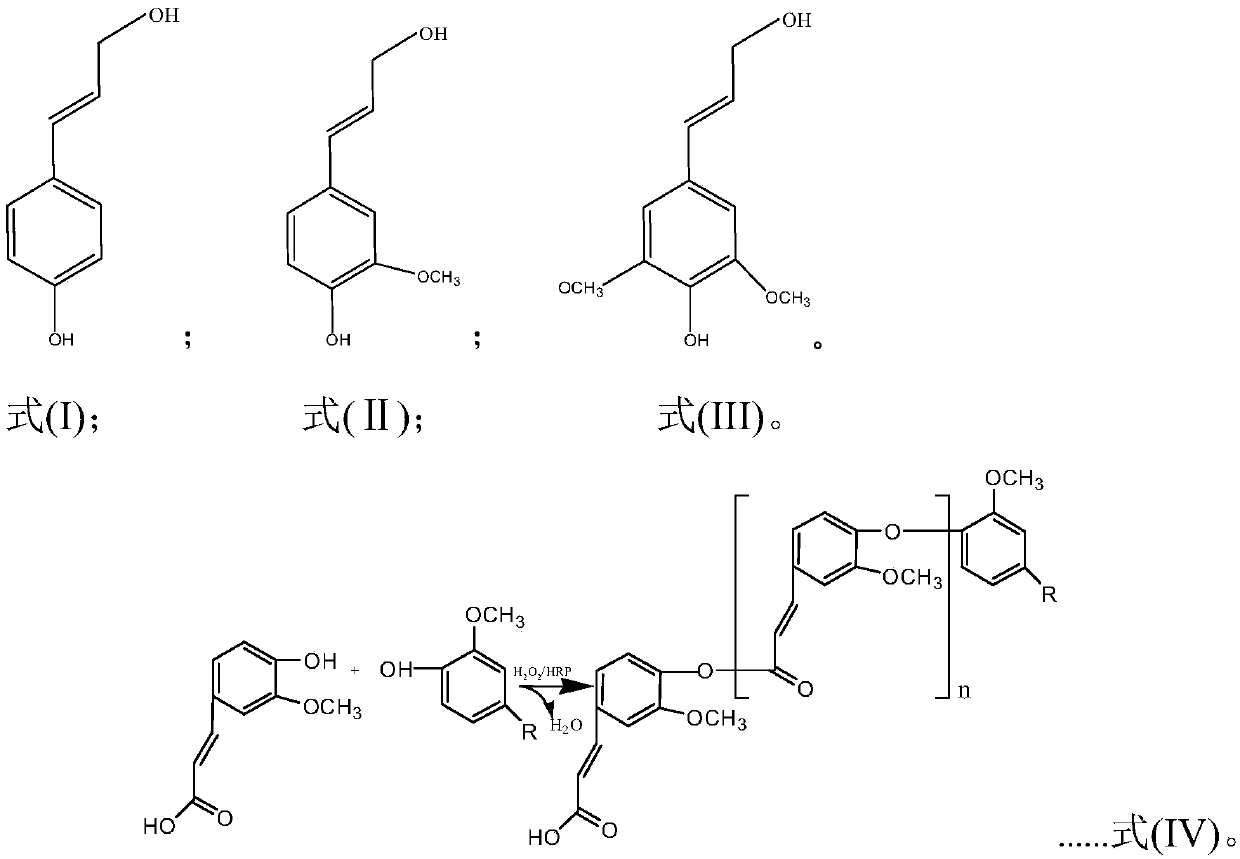

[0032] Step S01. Grafting natural lignin with ferulic acid;

[0033] Step S02. Prepare a solution of ferulic acid grafted lignin and a cross-linking agent, and coat it on one surface of the polysulfone membrane support membrane layer, and then dry it to form an anti-pollution membrane layer;

[0034] Step S03. The m-phenylenediamine solution and the trimesoyl chloride solution are successively coated on the surface of the anti-fouling film layer, reacted and dried to obtain a dense film layer, and then rinsed and dried to obtain a bio-fouling reaction Permeable membrane.

[0035] Wherein, before the step of grafting lignin with ferulic acid, an extraction step of lignin may also be included.

[0036] In a preferred embodiment, the extraction method of lignin is as follows:

[0037] 1) Mix the dried crop ste...

Embodiment 1

[0063] (1) Extraction of lignin:

[0064] After crushing the sorghum straw, dry it at 60°C for 24 hours;

[0065] The dried sorghum straw powder was mixed with 2M sodium hydroxide solution in a mass ratio of 1:10, and heated in an oven at 60°C for 12 hours; the heated mixture was separated by a centrifuge at a speed of 5000 rpm for 15 minutes, Take the supernatant;

[0066] Adjust the pH value of the supernatant to 4.0 with 5M sulfuric acid, place it in an environment of 4°C for 12 hours, separate it with a centrifuge at a speed of 5000 rpm for 15 minutes, and collect the precipitated lignin;

[0067] After the collected lignin is dried, it is dissolved in a 0.5M sodium hydroxide solution so that the mass fraction of the lignin in the solution is 1%.

[0068] (2) Grafting treatment of ferulic acid:

[0069] Use 2M hydrochloric acid to adjust the sodium hydroxide solution containing 1wt% lignin in step (1) to make the pH=6.0, and then mix with 105mM potassium phosphate buffer solution in...

Embodiment 2

[0078] (1) Extraction of lignin:

[0079] After crushing the sorghum straw, dry it at 60°C for 24 hours;

[0080] Take the dried sorghum straw powder and 2M sodium hydroxide solution in a mass ratio of 1:10 for mixing treatment, and place it in an oven at 60°C for 12 hours; the heated mixture is passed through a centrifuge at 5000 rpm Rotate for 15 minutes and take the supernatant;

[0081] Adjust the pH value of the supernatant to 4.0 with 5M sulfuric acid, place it in an environment of 4°C for 12 hours, separate it with a centrifuge at a speed of 5000 rpm for 15 minutes, and collect the precipitated lignin;

[0082] After the collected lignin is dried, it is dissolved in deionized water so that the mass fraction of the lignin in the solution is 1%, heated to 60°C, and stored in an environment of 60°C.

[0083] (2) Coating treatment of lignin:

[0084] Using glyoxal as the solute, the glyoxal was dissolved in deionized water to prepare a 10 wt% crosslinking agent solution. The lignin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com