Method for performing surface treatment on material for boosting cell growth and resisting biological pollution

An anti-biological pollution and surface treatment technology, applied in the direction of coating, can solve the problems of low graft density and difficult to increase graft density, and achieve the effects of improving graft density, control of reaction conditions, and good anti-biological pollution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

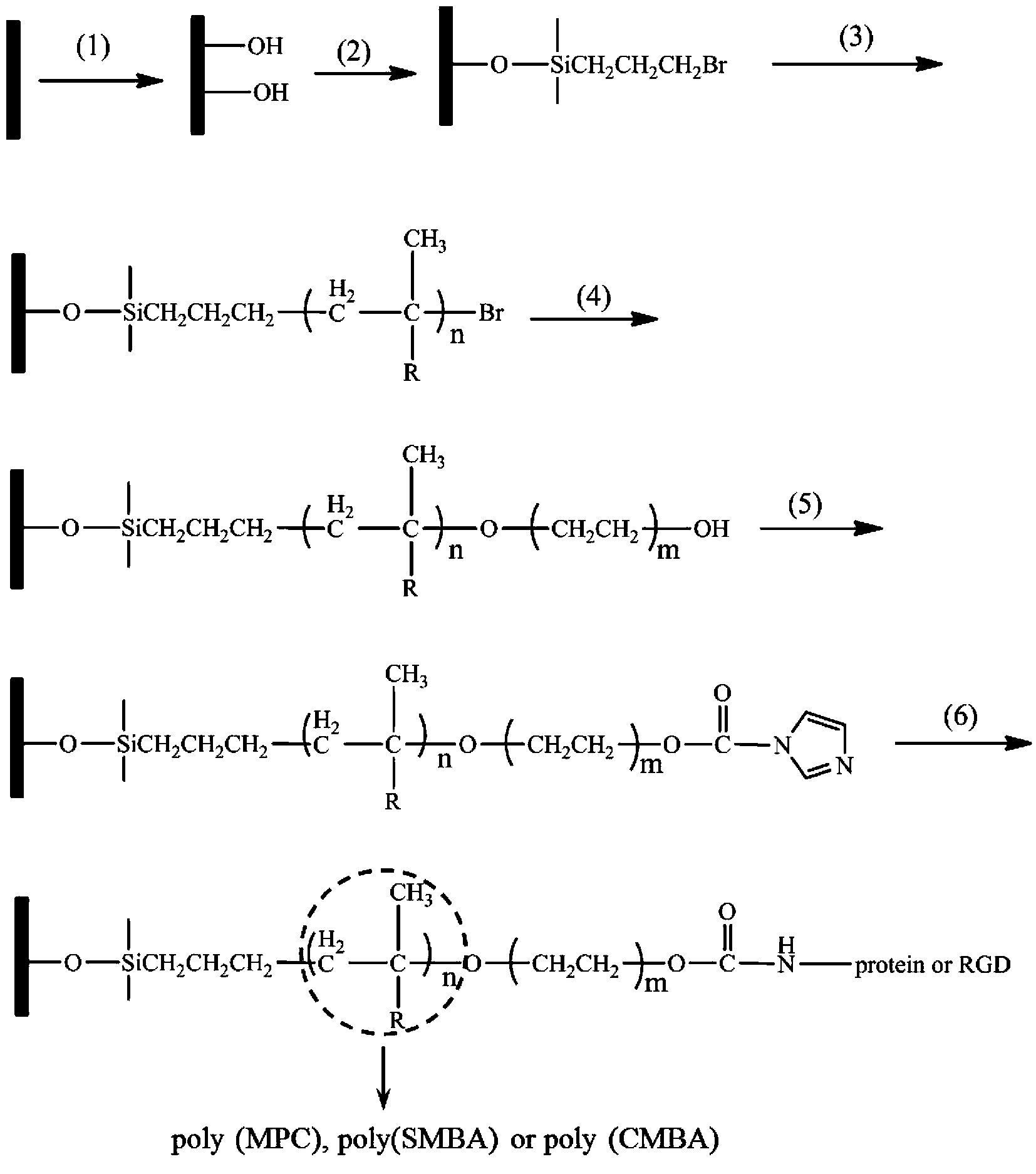

[0023] Embodiment 1: according to the following steps, the surface of the material is treated

[0024] (1) Material surface activation: Cut the Ti6Al4V material into discs with a diameter of 1.5 cm and a thickness of 1 mm. After the surface is polished to a mirror surface, it is ultrasonically cleaned with acetone, ethanol, and distilled water for 10 minutes, and immersed in a mixed solution of concentrated sulfuric acid and hydrogen peroxide. Medium (sulfuric acid: hydrogen peroxide = 70:30 (v / v)) was treated for 30 minutes, then taken out, then washed with a large amount of deionized water, dried for later use;

[0025] (2) Material surface bromination: firstly prepare a toluene solution of 3-bromopropyltrimethoxysilane with a concentration of 10mM, immerse the surface-activated Ti6Al4V disk into 20ml of the prepared silane solution, self-assemble for 12 hours, take out Afterwards, use toluene, acetone, and deionized water to ultrasonically clean for 10 minutes in sequence, ...

Embodiment 2

[0028] Embodiment 2: Treat the surface of the material according to the following steps (alkali treatment)

[0029] (1) Material surface activation: Cut the Ti6Al4V material into discs with a diameter of 1.5cm and a thickness of 1mm. After the surface is polished to a mirror surface, it is ultrasonically cleaned with acetone, ethanol, and distilled water for 10 minutes, and immersed in 80% sodium hydroxide solution. After 6 hours of medium treatment, take it out, then wash it with a large amount of deionized water, and dry it for later use;

[0030] (2) Material surface bromination: immerse the surface-activated Ti6Al4V in 20ml of 10mM 3-bromopropyltrimethoxysilane toluene solution for self-assembly reaction for 12 hours, take it out and ultrasonically clean it with toluene, acetone, and deionized water in sequence Dry after 10 minutes for later use;

[0031] (3) Grafted anti-biopyridine molecules: Weigh 0.054 g CuBr and 3.0 g MPC respectively, dissolve them in 20 ml methanol...

Embodiment 3

[0033] Embodiment 3: according to the following steps, the material surface is processed

[0034] (1) Material surface activation: Cut the Ti6Al4V material into discs with a diameter of 1.5cm and a thickness of 1mm, polish the surface to a mirror surface, and then ultrasonically clean it with acetone, ethanol, and distilled water for 10 minutes, and put it into the vacuum chamber of the plasma processor After vacuuming, treat with oxygen plasma for 10 minutes, wash the sample with a large amount of deionized water after taking it out, and dry it for later use;

[0035] (2) Material surface bromination: first prepare a toluene solution of 3-bromopropyltrimethoxysilane with a concentration of 10mM, immerse the surface-activated Ti6Al4V disk into 20ml of silane solution, stir and react for 24 hours, take it out with toluene, Acetone and deionized water were ultrasonically cleaned for 10 minutes in sequence, then dried for later use;

[0036] (3) Grafted anti-biopyridine molecule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com