Copper-based catalyst and preparation method thereof

A copper-based catalyst and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve poor stability, deactivation, methyl bromide conversion rate, low dimethyl ether selectivity, etc. problems, to achieve the effect of excellent performance, mild reaction conditions, simple and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

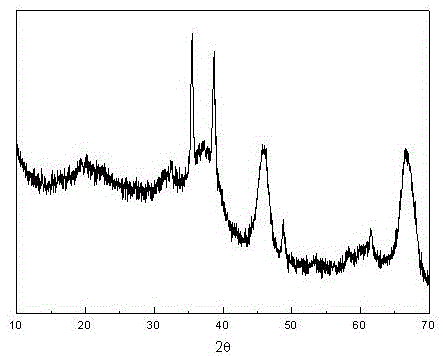

Image

Examples

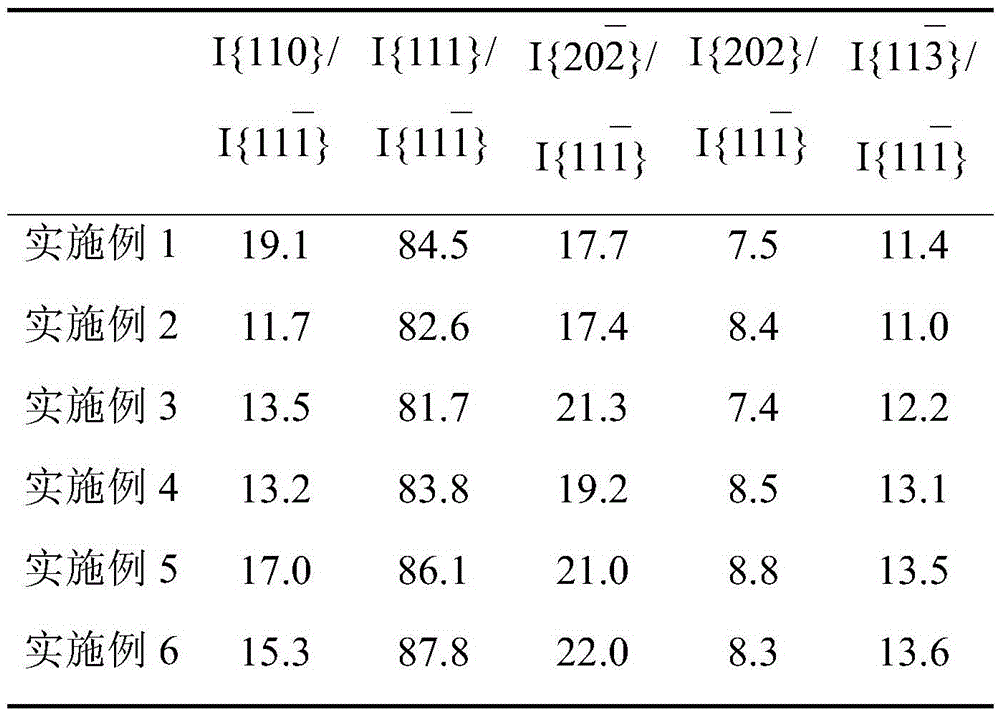

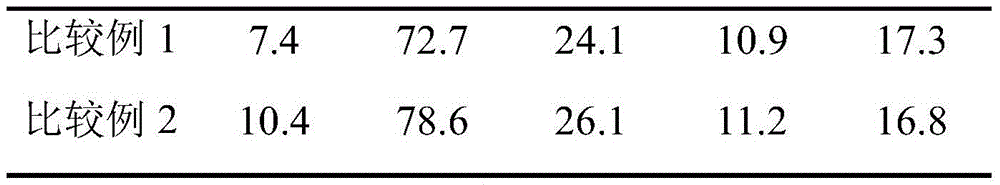

Embodiment 1

[0037] According to the ratio that isopropanol mass percentage is 4.1%, AEO-7 mass percentage is 0.8%, triethanolamine mass percentage is 1.5%, isopropanol, AEO-7, triethanolamine are added to deionized water, prepare solution; According to Cu The element accounts for 15.2% of the mass percentage of the catalyst, the Zr element accounts for 3.2% of the catalyst mass percentage, and the La element accounts for 1.5% of the catalyst mass percentage. Copper nitrate, zirconium oxychloride and lanthanum nitrate are added to the solution, stirred and dissolved to completely prepare The impregnation solution was obtained, and then impregnated with 10 g of alumina carrier in equal volume, aged at room temperature for 8 hours, and dried at 120° C. for 24 hours. The obtained material was placed in a tube furnace and heated to 130° C. under nitrogen, treated with 65% water vapor-35% nitrogen mixture for 2.5 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was...

Embodiment 2

[0039] According to the ratio that isopropanol mass percentage is 2.5%, AEO-7 mass percentage is 1.9%, triethanolamine mass percentage is 0.6%, isopropanol, AEO-7, triethanolamine are added to deionized water, prepare solution; According to Cu The element accounted for 20.2% by mass of the catalyst, the Zr element accounted for 1.1% by mass of the catalyst, and the La element accounted for 0.8% by mass of the catalyst. Add copper nitrate, zirconium oxychloride and lanthanum nitrate to the solution, stir and dissolve to completely prepare The impregnation solution was obtained, and then impregnated with 10 g of alumina carrier in equal volume, aged at room temperature for 10 h, and dried at 80° C. for 48 h. The obtained material was placed in a tube furnace and heated to 145°C under nitrogen, treated with 55% water vapor-45% nitrogen mixture for 3 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was calcined at 550° C. for 10 h; the catalyst was pr...

Embodiment 3

[0041] According to the ratio that isopropanol mass percentage is 4.8%, AEO-7 mass percentage is 1.7%, triethanolamine mass percentage is 1.1%, isopropanol, AEO-7, triethanolamine are added to deionized water, prepare solution; According to Cu The element accounts for 15.5% of the mass percentage of the catalyst, the Zr element accounts for 2.0% of the catalyst mass percentage, and the La element accounts for 2.5% of the catalyst mass percentage. Copper nitrate, zirconium oxychloride and lanthanum nitrate are added to the solution, stirred and dissolved to completely prepare The impregnation solution was obtained, and then impregnated with 10 g of alumina carrier in equal volume, aged at room temperature for 8 hours, and dried at 120° C. for 24 hours. The obtained material was placed in a tube furnace and heated to 130° C. under nitrogen, treated with 50% water vapor-50% nitrogen mixture for 4 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com