Method for preparing nano layered g-C3N4/Ag@AgCl composite photocatalytic material

A composite photocatalysis, nano-layered technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low reusability, low catalytic performance, etc. The effect of large specific surface area and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

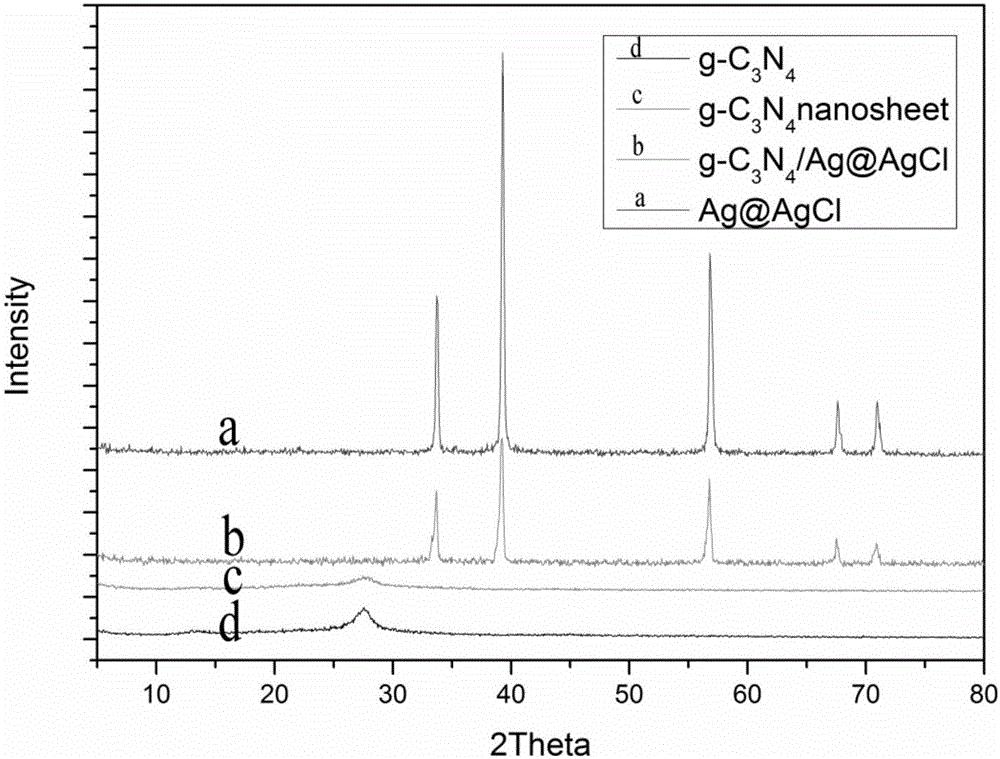

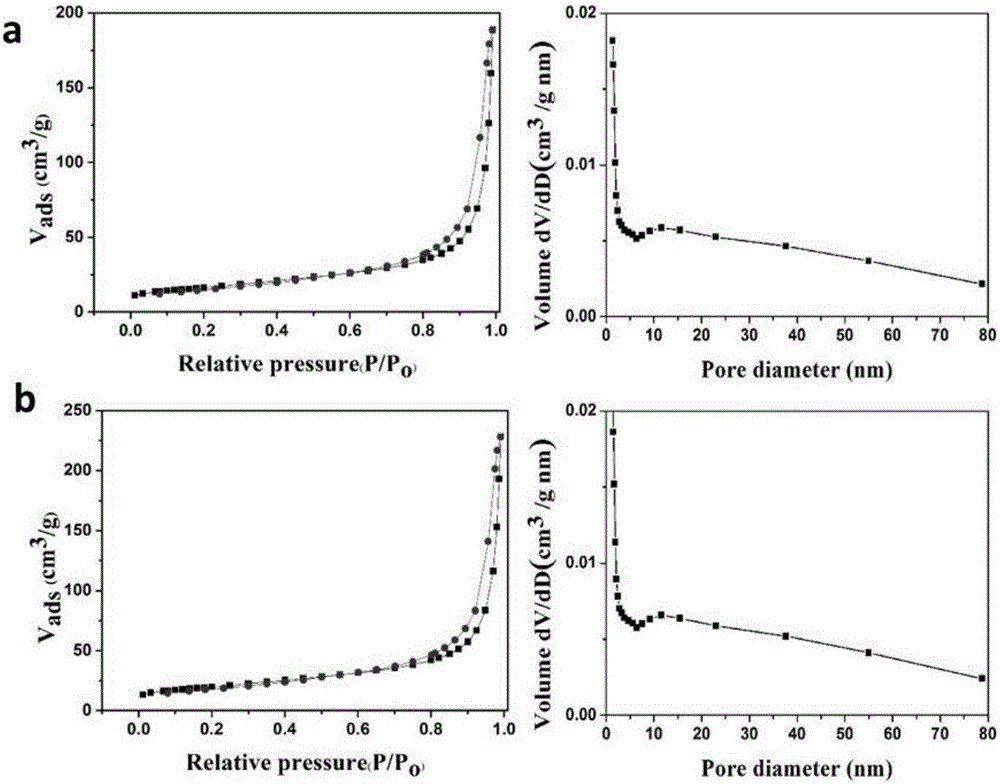

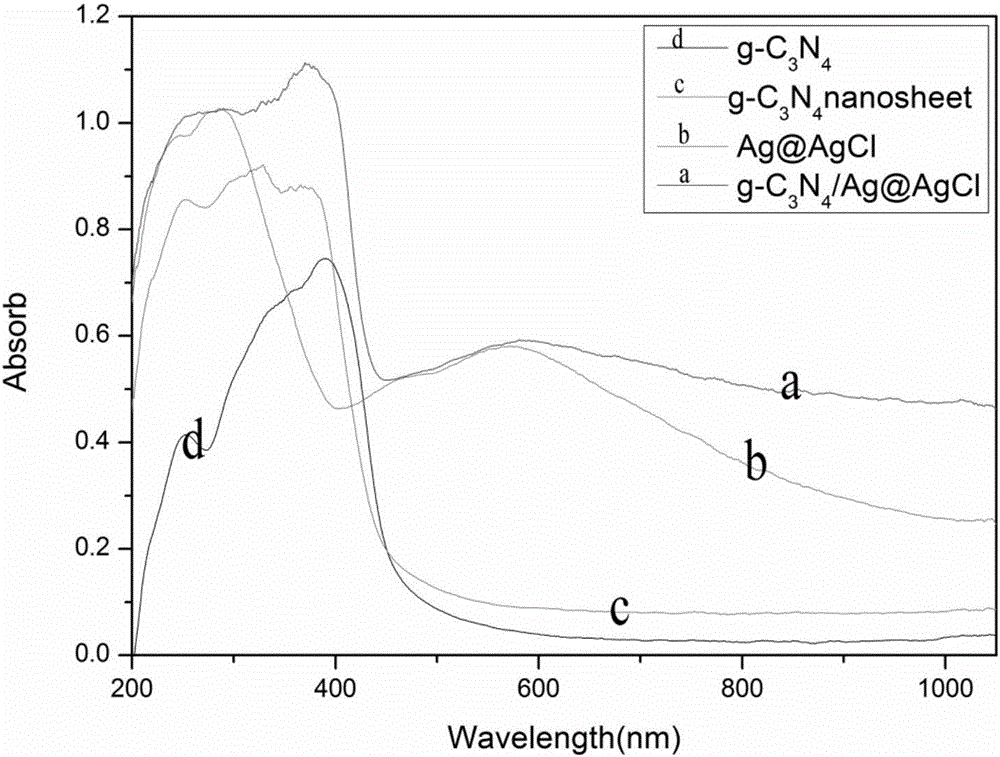

[0029] First prepare porous graphite phase carbon nitride powder, weigh 30g of urea in a crucible, place it in a muffle furnace, raise the temperature to 160°C, keep it for 60min, the heating rate is 5°C / min, continue to heat up to 550°C, the heating rate 20°C / min, keep warm for 2h, take it out after cooling and grind it for later use; weigh 400mg of porous graphite phase carbon nitride powder and place it in a polytetrafluoroethylene liner, add 80mL of isopropanol, stir for 30min, and keep warm at 180°C After cooling for 12 hours, centrifuge to obtain a solid; add the above solid to 100mL water, and ultrasonically peel for 60min; centrifuge the liquid after ultrasonic peeling for 10min, and the centrifuge speed is 3000rpm, take the upper liquid and dry it to obtain nano-layered g-C 3 N 4 . Dissolve 0.1g of silver nitrate and 0.4g of PVP (K30) in 50mL of absolute ethanol to obtain a yellow solution; slowly drop 300μL of saturated sodium chloride solution into the above yellow...

Embodiment 2

[0031] First prepare porous graphite phase carbon nitride powder, weigh 30g of urea in a crucible, put it in a muffle furnace, raise the temperature to 170°C, keep it for 50min, the heating rate is 8°C / min, continue to heat up to 560°C, the heating rate at 25°C / min, keep warm for 2.5h, take it out after cooling and grind it for later use; weigh 400mg of porous graphite phase carbon nitride powder and place it in a polytetrafluoroethylene liner, add 80mL of isopropanol, stir for 30min, and heat at 165°C Insulate for 15 hours, cool and centrifuge to obtain a solid; add the above solid to 100mL of water, and ultrasonically peel for 50min; centrifuge the ultrasonically stripped liquid for 10min at a centrifuge speed of 3000rpm, take the upper liquid and dry to obtain nano-layered g-C 3 N 4 . Dissolve 0.1g of silver nitrate and 0.4g of PVP (K30) in 50mL of absolute ethanol to obtain a yellow solution; slowly drop 400μL of saturated sodium chloride solution into the above yellow so...

Embodiment 3

[0033] First prepare porous graphite phase carbon nitride powder, weigh 30g of urea in a crucible, put it in a muffle furnace, raise the temperature to 180°C, keep it for 40min, the heating rate is 10°C / min, continue to heat up to 580°C, the heating rate 30°C / min, keep warm for 2h, take it out after cooling and grind it for later use; weigh 400mg of porous graphite phase carbon nitride powder and place it in a polytetrafluoroethylene liner, add 80mL of isopropanol, stir for 30min, and keep warm at 150°C After cooling for 18 hours, centrifuge to obtain a solid; add the above solid to 100mL water, and ultrasonically strip it for 40min; centrifuge the liquid stripped by ultrasonic for 10min, the speed of the centrifuge is 3000rpm, take the upper liquid and dry it to obtain nano-layered g-C 3 N 4 . Dissolve 0.1g of silver nitrate and 0.4g of PVP (K30) in 50mL of absolute ethanol to obtain a yellow solution; slowly drop 500μL of saturated sodium chloride solution into the above ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com