Heat-insulating anti-freezing electric vehicle battery shell material and preparation method thereof

A technology for electric vehicle batteries and shell materials, applied in the field of electric vehicle manufacturing, can solve the problems of only focusing on mechanical strength, limited heat insulation and antifreeze effect, etc., and achieves good processability, excellent heat insulation and antifreeze effect, impact resistance and resistance. Good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 10 parts of polyethylene terephthalate and 5 parts of powdered nitrile rubber to 15 parts of bismaleimide resin, and heat up to 125-130°C at a heating rate of 5°C / min Mix for 30 minutes, then add 3 parts of polyethylene oxide, 2 parts of weathering aids and 0.5 parts of diphenylmethane bismaleimide, continue to heat and mix at 125-130°C for 15 minutes, and then naturally cool to room temperature to obtain material I;

[0027] (2) Add 10 parts of plastic beverage bottle cap regenerated particles and 3 parts of terpene resin to 10 parts of polyvinyl chloride paste resin, and heat up to 80-85°C at a temperature increase rate of 5°C / min for 30 minutes, then add 3 parts of modified asbestos wool and 1 part of ethoxylated trimethylolpropane triacrylate, continue to heat up to 120-125°C and keep mixing for 15 minutes, and then naturally cool to room temperature to obtain material II;

[0028] (3) Add material II, 2 parts of sepiolite fiber and 0.5 part of barium metaborate ...

Embodiment 2

[0033] (1) Add 10 parts of polyethylene terephthalate and 5 parts of powdered nitrile rubber to 15 parts of bismaleimide resin, and heat up to 125-130°C at a heating rate of 5°C / min Mix for 30 minutes, then add 3 parts of polyethylene oxide, 2 parts of weathering aids and 0.5 parts of diphenylmethane bismaleimide, continue to heat and mix at 125-130°C for 15 minutes, and then naturally cool to room temperature to obtain material I;

[0034] (2) Add 10 parts of plastic beverage bottle cap regenerated particles and 3 parts of terpene resin to 10 parts of polyvinyl chloride paste resin, and heat up to 80-85°C at a temperature increase rate of 5°C / min for 30 minutes, then add 4 parts of modified asbestos wool and 1 part of ethoxylated trimethylolpropane triacrylate, continue to heat up to 120-125°C and keep mixing for 15 minutes, and then naturally cool to room temperature to obtain material II;

[0035] (3) Add material II, 2 parts of sepiolite fiber and 0.5 part of barium metaborate ...

Embodiment 3

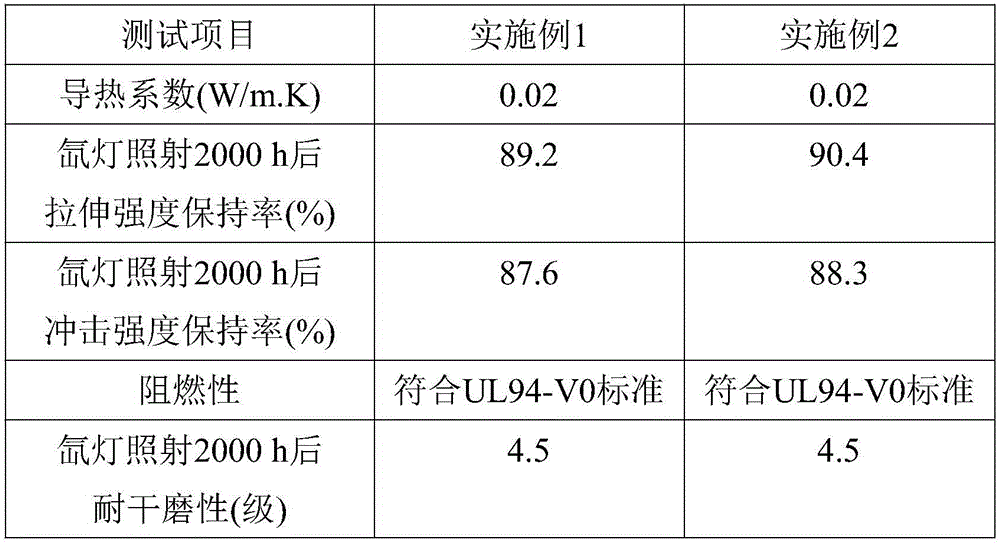

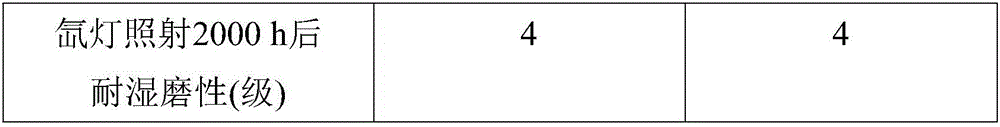

[0040] Performance tests were performed on the battery casing materials prepared in Example 1 and Example 2, and the test results are shown in Table 1.

[0041] Table 1 Performance test results of the battery casing materials prepared in the embodiment

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com