A kind of preparation method of n-doped carbon quantum dots and its products and applications

A technology of carbon quantum dots, which is applied in the field of preparation of N-doped carbon quantum dots, can solve the problems that carbon dots are in the preliminary stage, and achieve the effects of good water solubility, improved efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

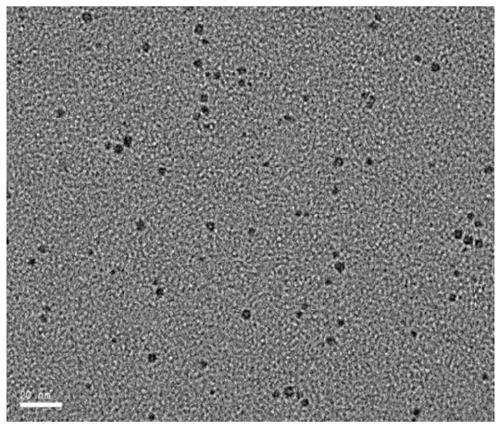

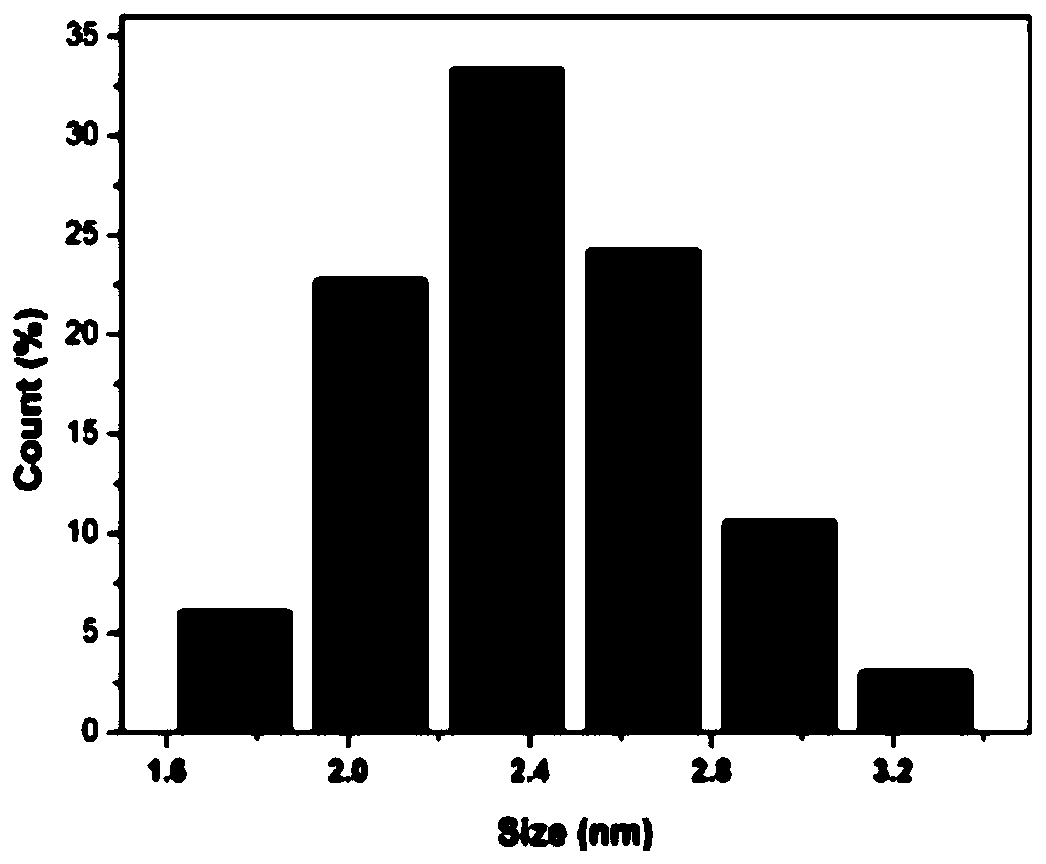

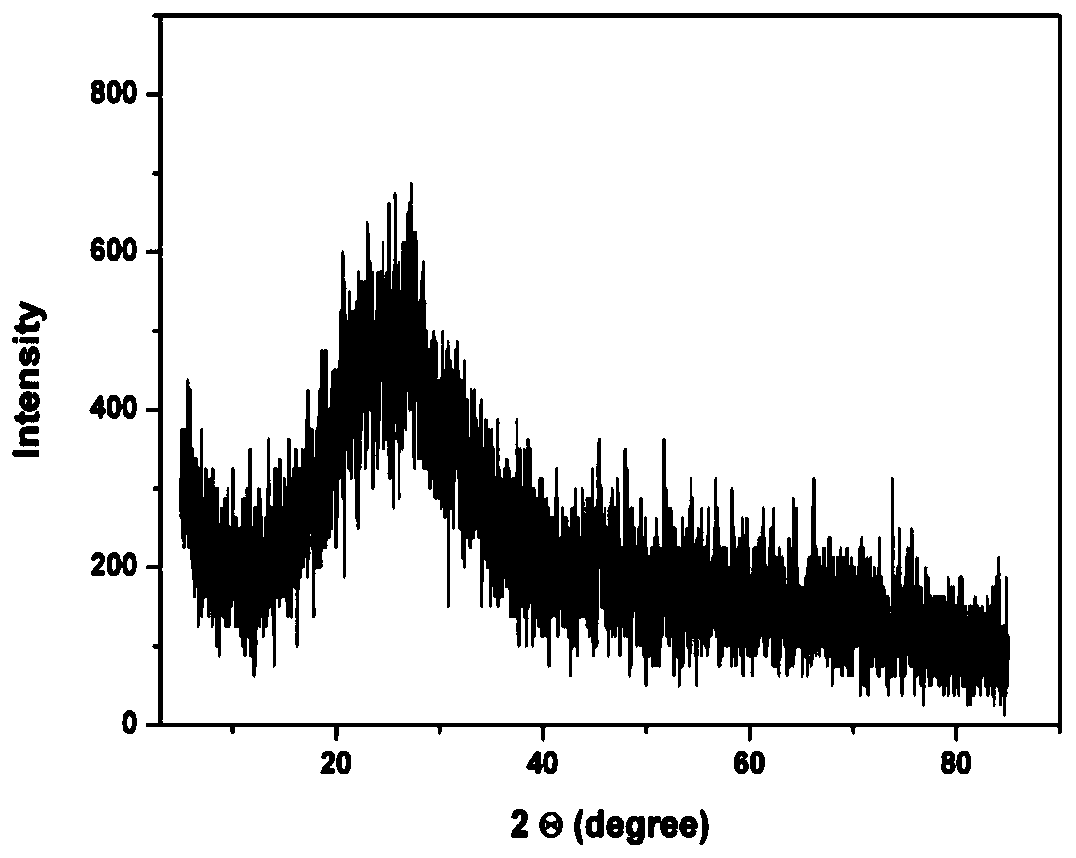

[0039] Preparation of N-doped carbon quantum dots:

[0040] Step 1, weigh 0.5g of chitosan (degree of deacetylation is 90%, viscosity is 400mPa s) powder and place it in a clean 50mL beaker, add 25mL of deionized water, and stir at 600rpm at 20°C 20min.

[0041] Step 2, transfer the colorless solution to a polytetrafluoroethylene hydrothermal reaction kettle, place it in a vacuum drying oven, and heat at a constant temperature of 200° C. for 10 h.

[0042] Step 3, after the reaction is completed, the product to be synthesized is naturally cooled to 20°C.

[0043] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0044] Step 5, vacuum freeze-dry the obtained clear carbon quantum dot solution at a temperature of -50° C. for 24 hours and a vacuum of 9.6 Pa to obtain N-doped fluorescent carbon quantum dot po...

Embodiment 2

[0052] Preparation of N-doped carbon quantum dots:

[0053] Step 1, weigh 0.5g of chitosan (degree of deacetylation is 95%, viscosity is 50mPa s) is placed in a clean 50mL beaker, add 25mL of deionized water, and stir at 400rpm for 30min at 25°C , a colorless and transparent aqueous solution was obtained.

[0054] Step 2: Transfer the colorless solution to a polytetrafluoroethylene hydrothermal reaction kettle, place in a vacuum drying oven, and heat at a constant temperature of 200° C. for 8 hours.

[0055] Step 3, after the reaction is completed, the product to be synthesized is naturally cooled to 10°C.

[0056] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0057] Step 5, the obtained clear carbon quantum dot solution is vacuum freeze-dried at -50°C for 24 hours and the vacuum degree is 9.6Pa to o...

Embodiment 3

[0060] Preparation of N-doped carbon quantum dots:

[0061] Step 1, weigh 0.5g of chitosan (degree of deacetylation is 90%, viscosity is 800mPa·s) is placed in a 50mL clean beaker, add 30mL of deionized water, and stir at 500rpm for 20min at 10°C , a colorless and transparent aqueous solution was obtained.

[0062] Step 2, transfer the colorless solution to a polytetrafluoroethylene hydrothermal reaction kettle, place in a vacuum drying oven, and heat at a constant temperature of 190°C for 12h.

[0063] Step 3, after the reaction is completed, the product to be synthesized is naturally cooled to 20°C.

[0064] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0065] Step 5, vacuum freeze-dry the obtained clear carbon quantum dot solution at a temperature of -54°C for 24 hours and a vacuum of 9.6 Pa to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com