Metal cutting fluid and preparation method thereof

A technology of metal cutting fluid and corrosion inhibitor, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of reduced service life of cutting fluids, and achieve the effect of excellent lubricating performance and good general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Synthetic corrosion inhibitors:

[0054] Add 10 parts of organic alcohol amine, 2 parts of petroleum sulfonate, 2 parts of vegetable oleic acid, 1 part of tall oil acid, and 8 parts of boric acid monoethanolamine into the stirring reaction kettle in turn, and then heat it to 100-160 degrees. Then keep it warm for 30-40 minutes, after cooling, add 5 parts of silane coupling agent and 1 part of fluozirconic acid or fluotitanic acid, and stir evenly to obtain the required corrosion inhibitor.

[0055] Preparation of metalworking fluids

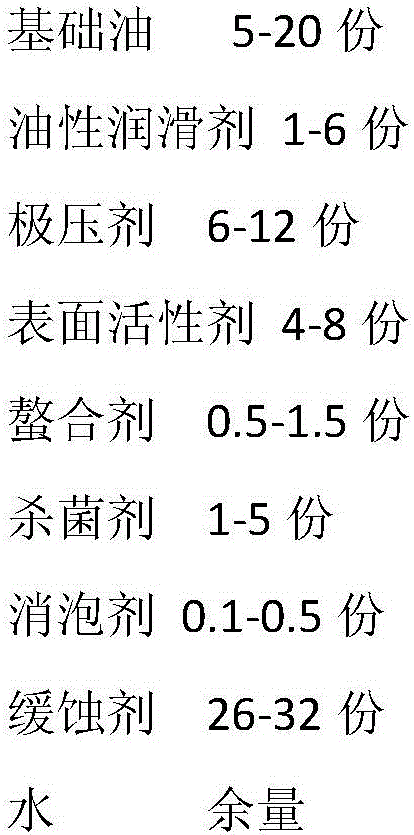

[0056] Add 10 parts of base oil, 2 parts of oily lubricant, 8 parts of extreme pressure agent, 4.5 parts of surfactant, 1 part of chelating agent, 3 parts of bactericide, 0.2 parts of defoamer, and 29 parts of corrosion inhibitor in the mixing tank and 42.3 parts of water, and finally obtain a metalworking fluid with a total mass of 100 parts.

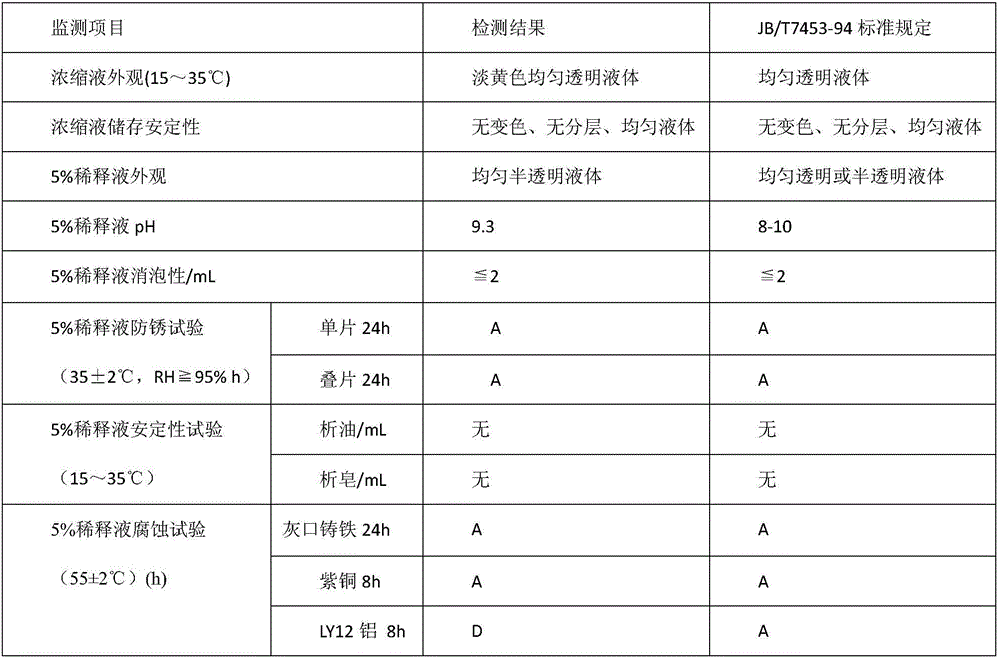

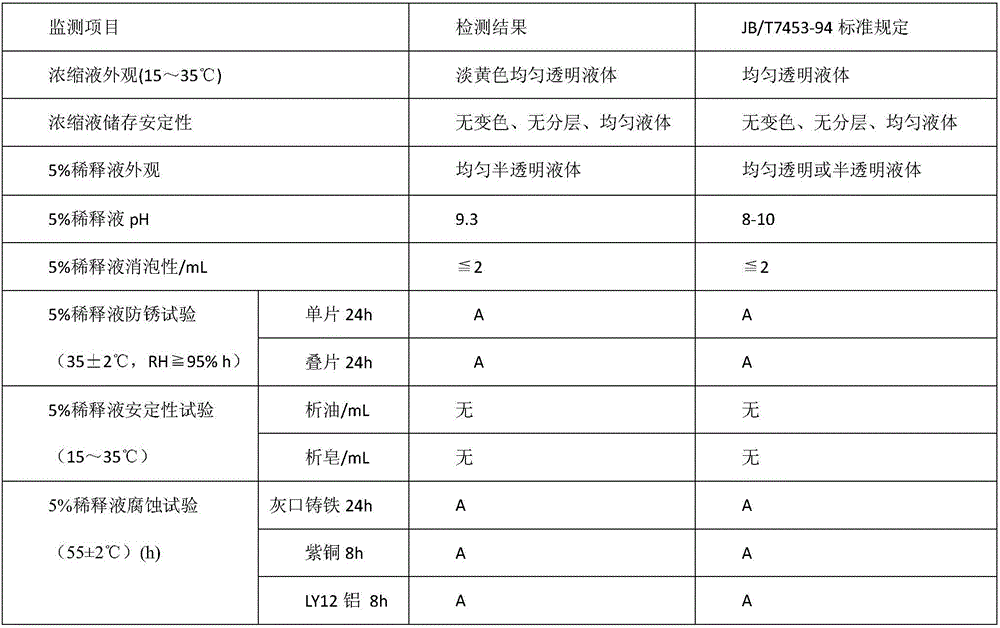

[0057] The performance of the cutting fluid is as follows:

[0058] Table 2

[0059]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com