Sulfur-nitrogen dual-doped graphene nano material and preparation method and application thereof

A nanomaterial, graphene technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of battery efficiency and capacity decay, poor sulfur conductivity, and limited improvement of host materials, etc. To achieve the effect of improving conductivity and enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

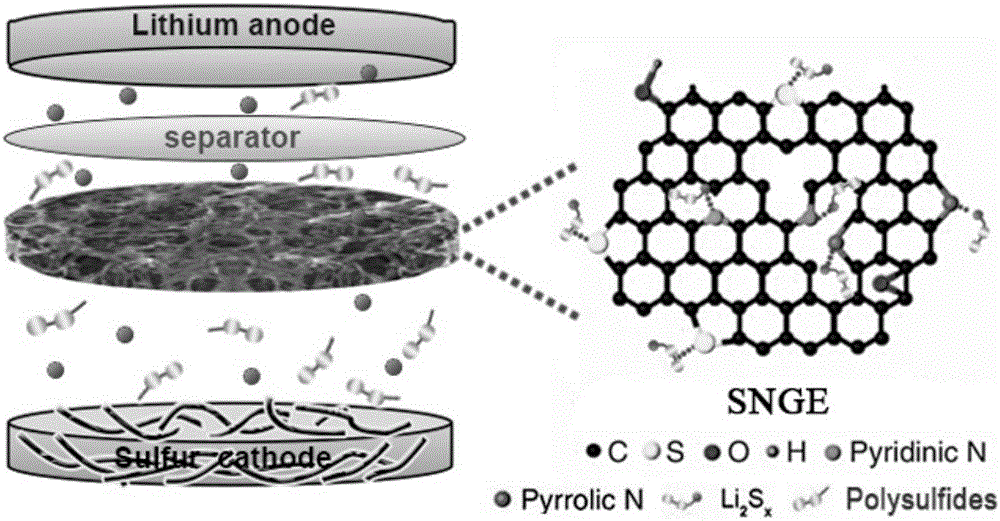

[0038] A. Preparation of sulfur and nitrogen double-doped graphene nanomaterials

[0039] (1) Weigh 600 mg of thiourea and 300 mg of graphene oxide, mix and dissolve in 50 mL of ethanol, stir vigorously and ultrasonically disperse evenly, then dry the mixed liquid in a water bath at 80 ° C to obtain a composite of graphene oxide and thiourea .

[0040] (2) Under the protection of an argon atmosphere, the composite of graphene oxide and thiourea obtained in step (1) was kept at 900° C. for 4 h, and then naturally cooled to room temperature to obtain a sulfur-nitrogen double-doped graphene nanomaterial.

[0041] B. Preparation of positive electrode sheets for lithium-sulfur secondary batteries

[0042] Fully grind and mix 250 mg of carbon nanotubes (Nanjing Xianfeng Nano Material Technology Co., Ltd., 5 g with a purity of 95%, a length of 0.5 to 2 microns, a carboxylation content of 3.86 wt %, XFM06) and 585 mg of elemental sulfur in 8 mL of carbon disulfide, and stir vigorousl...

Embodiment 2

[0050] A. Preparation of sulfur and nitrogen double-doped graphene nanomaterials

[0051] (1) Weigh 700 mg of thioamidourea and 330 mg of graphene oxide, mix and dissolve in 70 mL of ethanol, stir vigorously and disperse evenly by ultrasonic waves, and then dry the mixed liquid in a water bath at 80 ° C to obtain graphene oxide and thioamido Urea complexes.

[0052] (2) Under the protection of an argon atmosphere, place the composite of graphene oxide and thioaminourea obtained in step (1) at 850°C for 4 hours, and then cool naturally to room temperature to obtain a sulfur-nitrogen double-doped graphene nanomaterial .

[0053] B. Battery assembly and testing

[0054] Grind and mix 150mg of commercial carbon black (Nanjing Xianfeng Nano Material Technology Co., Ltd., 100g, particle size: 30-45nm, XFI15) and 350mg of elemental sulfur thoroughly, dissolve in 13mL of carbon disulfide, stir vigorously and ultrasonically, wait until the carbon disulfide is completely volatilized, ...

Embodiment 3

[0057] A. Preparation of sulfur and nitrogen double-doped graphene nanomaterials

[0058] (1) Weigh 650 mg of methionine and 320 mg of graphene oxide, mix and dissolve in 65 mL of ethanol, stir vigorously and disperse evenly by ultrasonic, then dry the mixed liquid in a water bath at 80°C to obtain graphene oxide and methionine acid complex.

[0059] (2) Under the protection of an argon atmosphere, place the composite of graphene oxide and methionine obtained in step (1) at 850°C for 4 hours, and then cool naturally to room temperature to obtain a sulfur-nitrogen double-doped graphene nanomaterial .

[0060] B. Battery assembly and testing

[0061] Grind and mix 150mg of commercial carbon fiber (Shanghai Tuoyang Biotechnology Co., Ltd., 1g, TAYC139875-1g) and 350mg of elemental sulfur thoroughly, dissolve in 12mL of carbon disulfide, stir vigorously and ultrasonically, until the carbon disulfide is completely volatilized, transfer the mixture to an oven, and heat up to 155°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com