High skin retention ceramide nano composition, and preparation method and applications thereof

A nano-composite, ceramide technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of slowing the absorption of active ingredients, hindering the transdermal absorption of ceramides, poor ceramide penetration, and the like, Achieve the effects of improving solubility and water dispersibility, increasing skin penetration, and improving skin permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

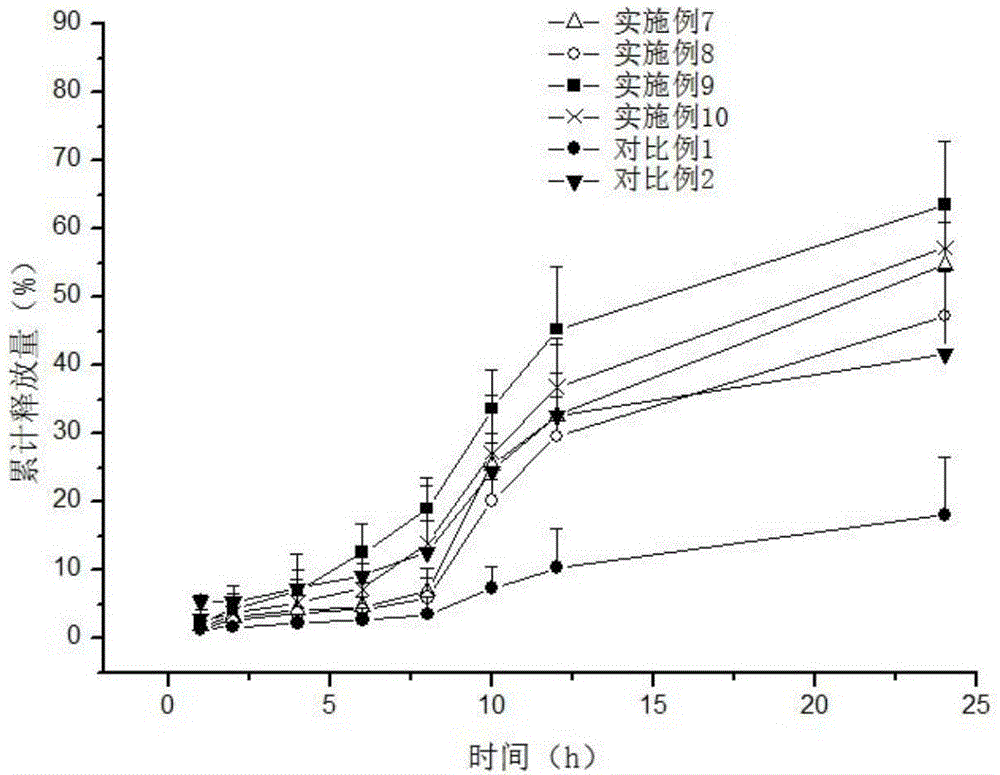

Examples

Embodiment 1

[0042] (1) Prepare the oil phase: melt 3.0% egg yolk phospholipid, 2.0% cholesterol, and 0.5% octyldodecanol in a 65°C water bath, add 0.5% ceramide I after melting, mix well, and set aside;

[0043] (2) Prepare the water phase: add 5.0% vitamin E polyethylene glycol succinate and 15.0% 1,3-butanediol to 74.0% water, stir and dissolve in a water bath at 65°C;

[0044] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2) and keep stirring, then emulsify at a high speed of 4000rpm for 10min to prepare a micron-scale dispersion;

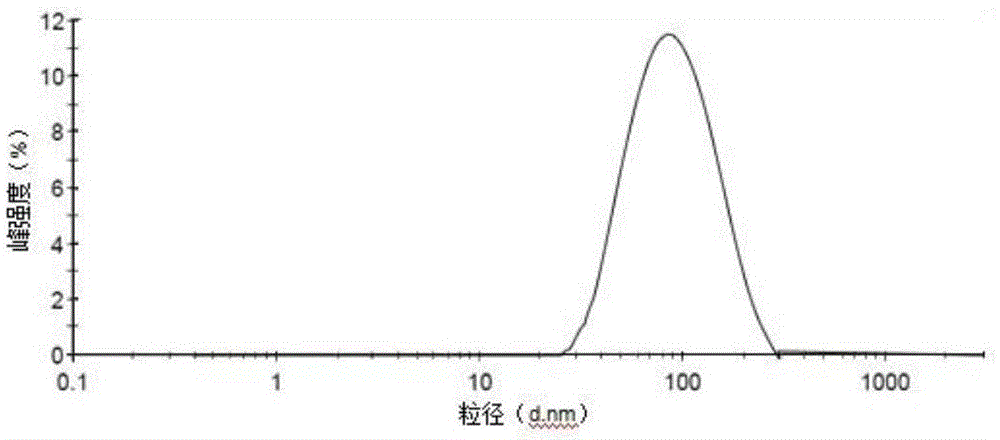

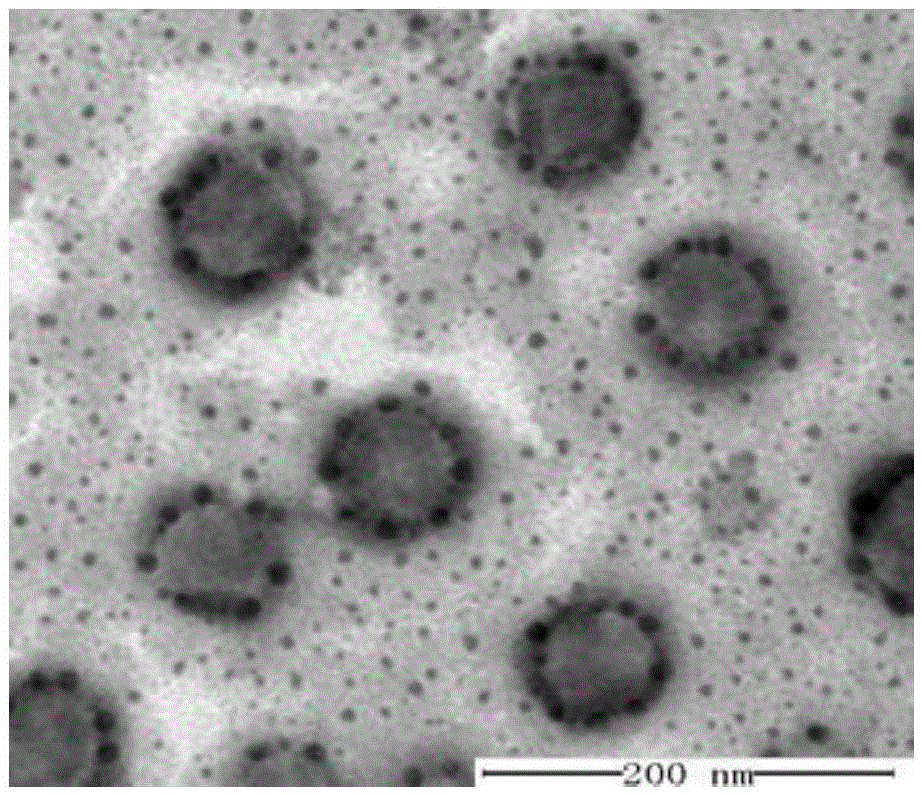

[0045] (4) Preparation of nano-composition: heat the nano-dispersion prepared in step (3) at 45° C., and then circulate through high-pressure homogenization at 500 bar for 10 times to obtain a ceramide nano-composition. The particle diameter of the ceramide nano composition is 59.3nm, and the encapsulation efficiency is 84.7%.

Embodiment 2

[0047] (1) Prepare the oil phase: melt 5.0% soybean lecithin, 3.0% cholesterol, and 1.0% octyldodecanol in a water bath at 90°C, then add 0.5% ceramide I and 0.5% ceramide II after melting, and mix well ,spare;

[0048] (2) Prepare the water phase: add 3.0% vitamin E polyethylene glycol succinate, 10.0% polyethylene glycol 400, and 20.0% propylene glycol into 57.0% water, stir and dissolve in a water bath at 90°C;

[0049] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2) and keep stirring, then emulsify at 6000rpm high-speed shear for 5min to make a micron-scale dispersion;

[0050] (4) Preparation of nano-composition: heat the nano-dispersion prepared in step (3) at 70° C., and then cycle through high-pressure homogenization at 1800 bar twice to obtain a ceramide nano-composition. The particle diameter of the ceramide nano composition is 72.8nm, and the encapsulation efficiency is 90.5%.

Embodiment 3

[0052] (1) Prepare the oil phase: put 2.0% egg yolk phospholipids, 5.0% dipalmitoylphosphatidylcholine, 1.0% distearoylphosphatidylcholine, 5.0% octyldodecanol, 5.0% cholesterol in a water bath at 70°C Make it melt; add 1.0% ceramide III A after melting, mix well, set aside;

[0053] (2) Prepare the water phase: add 0.5% vitamin E polyethylene glycol succinate and 10% propylene glycol to 70.5% water, stir and dissolve in a 70°C water bath;

[0054] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2) and keep stirring, then emulsify at 8000rpm high-speed shear for 3min to make a micron-scale dispersion;

[0055] (4) Preparation of nano-composition: heat the nano-dispersion prepared in step (3) at 50° C., and then cycle 7 times through high-pressure homogenization at 500 bar to obtain a ceramide nano-composition. The particle diameter of the ceramide nano composition is 79.3nm, and the encapsulation effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com