Hydrogenation protection agent and preparation method thereof

A hydrogenation protective agent and hydrogenation activity technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve metal waste, shorten start-up time, and improve activity Problems such as poor metal dispersion can be achieved to facilitate storage and transportation, shorten the start-up time, and shorten the operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 catalyst carrier

[0051] (1) Preparation of carrier A-1

[0052] Alumina-silica honeycomb ceramics are taken, with a porosity of 5% and an average pore diameter of 2.5 μm. Immerse in boric acid solution, dry at 120°C for 4 hours, and bake at 600°C for 3 hours to obtain carrier A-1, which contains 2wt% boron oxide and 15wt% silicon oxide.

[0053] (2) Preparation of carrier A-2

[0054] Alumina-silica honeycomb ceramics are used, with a porosity of 30% and an average pore diameter of 1.5 μm. Immerse in boric acid solution, dry at 120°C for 4 hours, and bake at 600°C for 3 hours to obtain carrier A-2, which contains 3wt% boron oxide and 12wt% silicon oxide.

Embodiment 2

[0055] Example 2 Preparation of hydrogenation protecting agent B

[0056] Weigh 6.0 g of ammonium molybdate, 4.6 g of nickel nitrate, and 15 mL of ammonia water, and mix them with deionized water to 100 mL to obtain impregnating solution I. Measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray the impregnation carrier A-1. After spraying, the sample was put into a blast drying oven for the first low-temperature heat treatment. The conditions for the first low-temperature heat treatment were: the temperature was raised to 80°C at a rate of 3°C / min, and the temperature was kept constant for 3 hours. Dissolve 6.0 g of 2,4,6-trimercapto-s-triazine triammonium salt in 50 mL of water to obtain impregnating solution II, spray the first low-temperature heat-treated sample with impregnating solution II, and then perform the second heat treatment. Low-temperature heat treatment conditions are: at 80°C, water vapor is 50% of the total volume,...

Embodiment 3

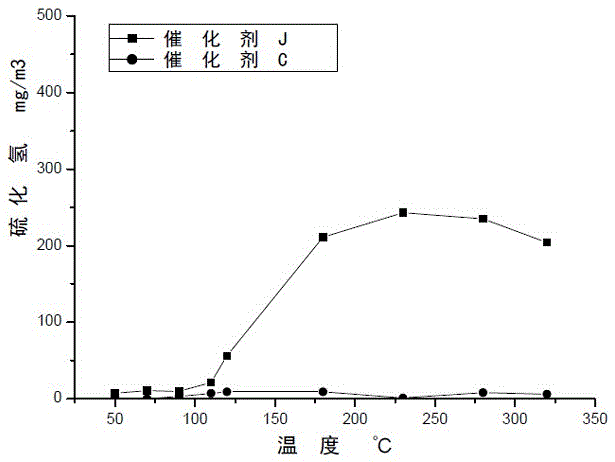

[0057] Example 3 Preparation of hydrogenation protecting agent C

[0058] Take 4.9g of molybdenum oxide, 2g of basic nickel carbonate, 0.5mL of phosphoric acid, and 50mL of deionized water and boil for 1 hour to obtain impregnation solution I. Measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray the carrier A-2. After the spraying is completed, put the sample into the blast drying oven for the first low-temperature heat treatment. The conditions for the first low-temperature heat treatment are: raise the temperature to 80°C at a rate of 3°C / min, and hold the temperature for 3 hours to obtain the first low-temperature heat treatment. For the sample, weigh 8.3g of 2,4-dimercapto-s-triazine diammonium salt and dissolve it in 50mL of water to obtain impregnation solution II. Spray and impregnate the first low-temperature heat treatment sample with impregnation solution II, and then perform the second low-temperature heat treatment , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com