Sewage treating system and process based on carbon-nitrogen separation

A carbon nitrogen and process technology, applied in the field of sewage treatment system and process based on carbon and nitrogen separation, can solve the problems of unstable anaerobic reactor, destroy the advantages of anaerobic reactor, and high investment cost, and achieve remarkable adsorption and removal effect. The effect of shortening the hydraulic retention time and avoiding the denitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

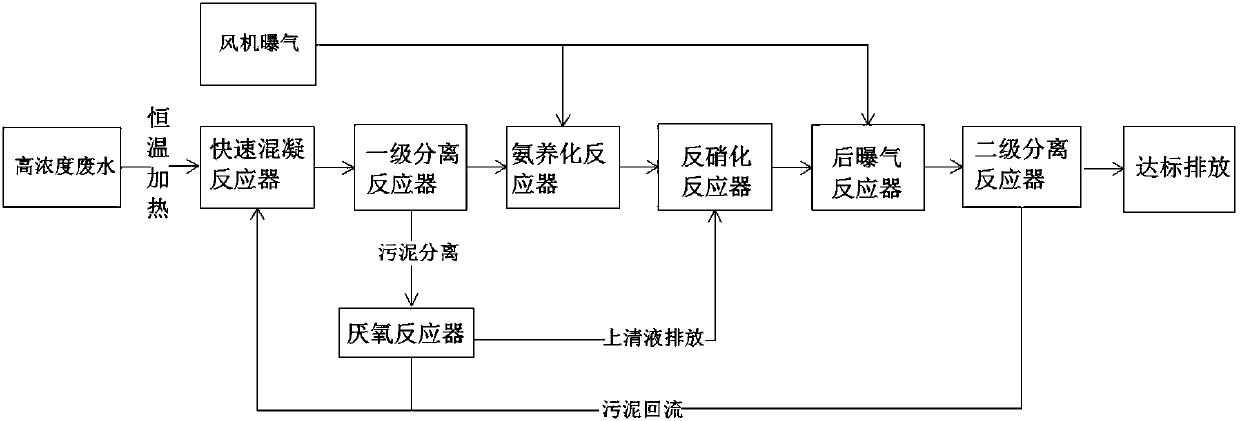

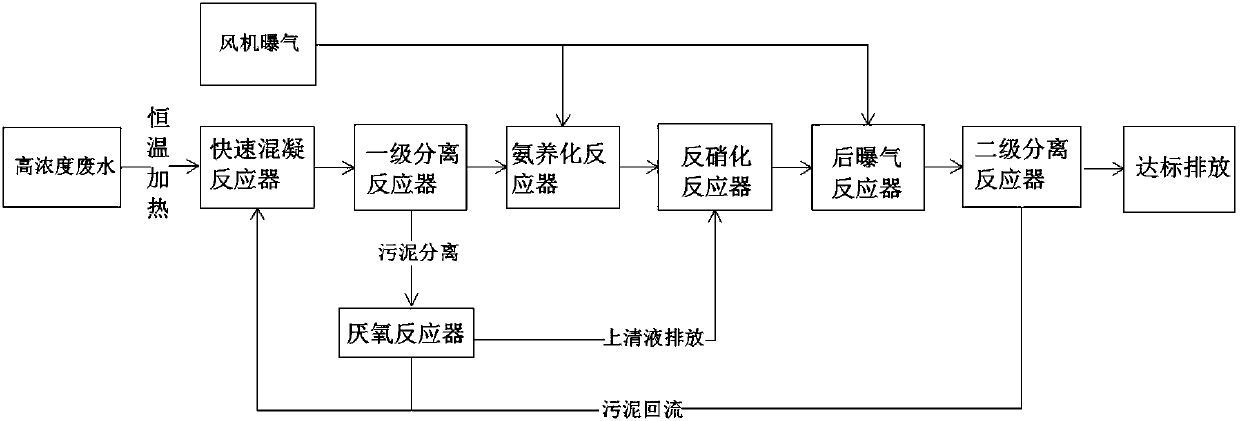

[0038] A low-consumption and high-efficiency sewage treatment system based on carbon and nitrogen separation, including constant temperature heating system, rapid coagulation reactor, primary separation reactor, anaerobic reactor, ammonia oxidation reactor, denitrification reactor, post-aeration reaction device, secondary separation reactor; the constant temperature heating system is connected to the rapid coagulation reactor, the outlet end of the rapid coagulation reactor is connected to the primary separation reactor, and the outlet section of the primary separation reactor is respectively connected to the anaerobic reaction The ammonia oxidation reactor and the ammonia oxidation reactor, the ammonia oxidation reactor, the denitrification reactor, the post-aeration reactor and the secondary separation reactor are connected in sequence, the bottom of the anaerobic reactor is provided with a sludge return system, and the sludge The sludge return system is connected to the rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com