A kind of waterless taphole clay of large and medium-sized blast furnace and its preparation method

A waterless blasting mud, large and medium-sized technology, applied in the field of metallurgical refractory materials, can solve the problems of poor erosion resistance, affecting normal production, poor blasting mud quality, etc., to improve the anti-erosion and anti-scouring capabilities, and reduce the porosity of the blasting mud , The effect of no cracks in the iron mouth hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

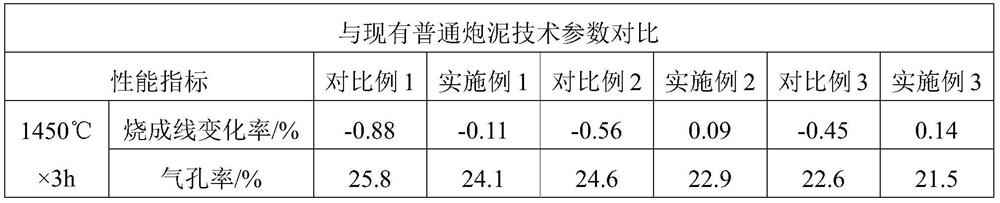

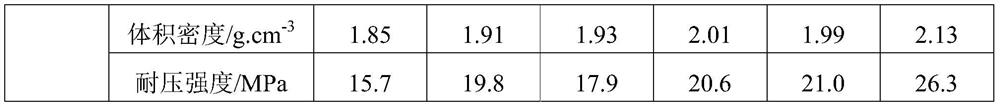

Examples

Embodiment 1

[0036] Weigh the powder according to parts by weight, including 1 part of metal silicon powder, 0.3 parts of metal aluminum powder, 2 parts of high-carbon resin powder, 5 parts of alumina micropowder, 1 part of silica fume, 0.1 part of sodium carboxymethyl cellulose, 0.2 parts of sodium phosphate, stirred at room temperature for 5 to 10 minutes and mixed evenly, to obtain the described micropowder additive for gun clay;

[0037]The preparation of gun mud is according to its components and parts by weight: 36.7 parts of high alumina bauxite aggregate, 9 parts of brown corundum fine powder, 10 parts of silicon carbide aggregate and fine powder, 15 parts of coke, 16 parts of plastic clay powder, 4 parts of asphalt powder; 9.3 parts of blast furnace taphole mud powder additive prepared in Example 1; 13 parts of tar.

[0038] In the preparation of gun mud, according to the ratio of the gun mud plan, the raw materials such as high alumina bauxite aggregate and fine powder, 90 silico...

Embodiment 2

[0041] Weigh the powder in parts by weight, including 2 parts of metal silicon powder, 0.5 parts of metal aluminum powder, 4 parts of high-carbon resin powder, 6 parts of alumina micropowder and 1.5 parts of silica fume. Stir at room temperature for 5 to 10 minutes after mixing evenly , to obtain the described micropowder additive for gun clay.

[0042] The preparation of gun mud is according to its components and parts by weight: 15 parts of high alumina bauxite aggregate, 20 parts of homogenized bauxite aggregate, 12 parts of corundum fine powder, 12 parts of silicon carbide, 12 parts of coke, and 12 parts of plastic clay powder 14 parts, 3 parts of asphalt powder; 14 parts of micropowder additives for blast furnace taphole mud made in Example 2; 12 parts of tar.

[0043] In the preparation of gun mud, according to the ratio of gun mud plan, raw materials such as high alumina bauxite aggregate, homogenized bauxite aggregate, corundum fine powder, silicon carbide aggregate an...

Embodiment 3

[0046] Weigh the powder according to parts by weight, stir at room temperature for 5 to 10 minutes and mix evenly to obtain the micropowder additive for gun clay; including 2.5 parts of metal silicon powder, 1.5 parts of metal aluminum powder, and 5 parts of high-carbon resin powder , 7 parts of alumina micropowder and 2 parts of silica fume.

[0047] The preparation of the mud is according to its components and parts by weight: 32.5 parts of brown corundum aggregate, 12 parts of corundum powder, 15 parts of silicon carbide, 12 parts of coke, 9 parts of plastic clay powder, and 2 parts of asphalt powder; prepared in Example 2 17.5 parts of micro-powder additives for blast furnace taphole clay; 12 parts of extra tar.

[0048] In the preparation of gun mud, according to the ratio of the gun mud plan, raw materials such as brown corundum aggregate, corundum fine powder, silicon carbide aggregate and fine powder, coke, plastic clay powder, asphalt powder, etc. are firstly mixed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com