Device and method for energy saving and consumption reduction of dimethyl carbonate device

A technology of dimethyl carbonate and methanol, applied in the purification/separation of carbonate/haloformate, preparation of carbonate/haloformate, separation method, etc., can solve the problem of high-consumption steam pressurized rectification Tower reaction temperature and pressure, waste of latent heat of condensation of methanol and dimethyl carbonate mixture, inability to achieve high-density quality monitoring, etc., to achieve the effect of increasing product monitoring frequency, obvious energy saving effect, and improving mass transfer and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

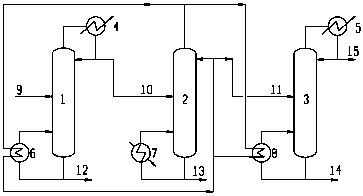

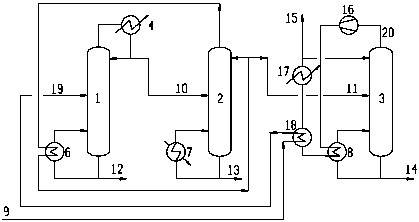

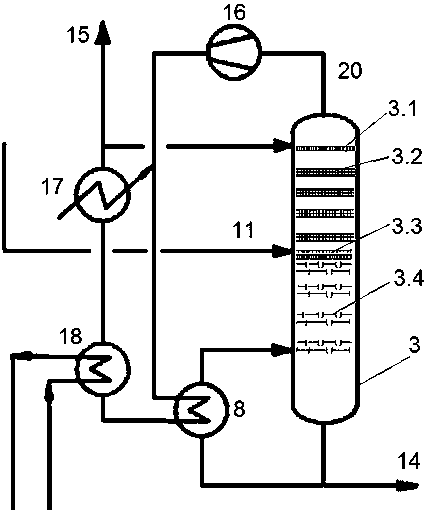

[0045] Embodiment 1: with reference to attached Figure 2-11 , a kind of method that the present invention mentions is used for the energy-saving and consumption-reducing method of dimethyl carbonate plant, comprises the following steps, following by mass percentage:

[0046] a) Propylene carbonate, methyl alcohol and methanol base catalyst mixture material 9 enter reaction rectification tower 1 after heat exchanger 18 and carry out preliminary reaction fractionation, and the propylene glycol 12 that reaction generates is discharged from the tower still bottom and goes to propylene glycol refining tower, and the dicarbonic acid that generates A part of the azeotrope of methyl ester and methanol is refluxed to the reactive distillation tower 1 after being condensed by the overhead condenser 4, and a part of the azeotrope 10 enters the pressurized rectification tower 2 for pressurized rectification;

[0047] b) after the separation of the pressurized rectification tower 2, the d...

Embodiment 2

[0082] Embodiment 2: a kind of method that the present invention mentions is used for the energy-saving and consumption-reducing method of dimethyl carbonate plant, differs from embodiment 1 in that: an online continuous detection and analysis device and method are added, and the specific devices include the following:

[0083] The dimethyl carbonate crude product discharged at pressurized rectification tower 2 is sent into dimethyl carbonate refining tower 21, and the bottom of dimethyl carbonate refining tower 21 discharges high-purity dimethyl carbonate, and the light components discharged from the top are sent again into the pressurized rectification tower 2 to continue circulation; in addition, the high-purity dimethyl carbonate produced is sent in the online synchronous detector 22, after the on-line quality detection of the online synchronous detector 22, it is sent into the dimethyl carbonate storage tank 23.

[0084] Among them, the online synchronous detector include...

Embodiment 3

[0091] Embodiment 3: with reference to attached Figure 12 , the only difference from Embodiment 2 is that the pressure relief device 28 used is also provided with an extension tube 28.5, and the extension tube 28.5 is a flat airtight tube, one end communicates with the main body 28.3 in the shape of a bell mouth, and the other end communicates with the The gas chromatograph has the advantage that the liquid after pressure relief passes through the flat closed tube and enters the gas chromatograph more smoothly, making the continuous measurement and analysis of the present invention more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com