Production method of cam plate

A production method and cam piece technology, which is applied in the field of alloy processing, can solve the problems of heavy weight of the camshaft and waste of materials, etc., and achieve the effects of small change in forging size, improved forgeability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

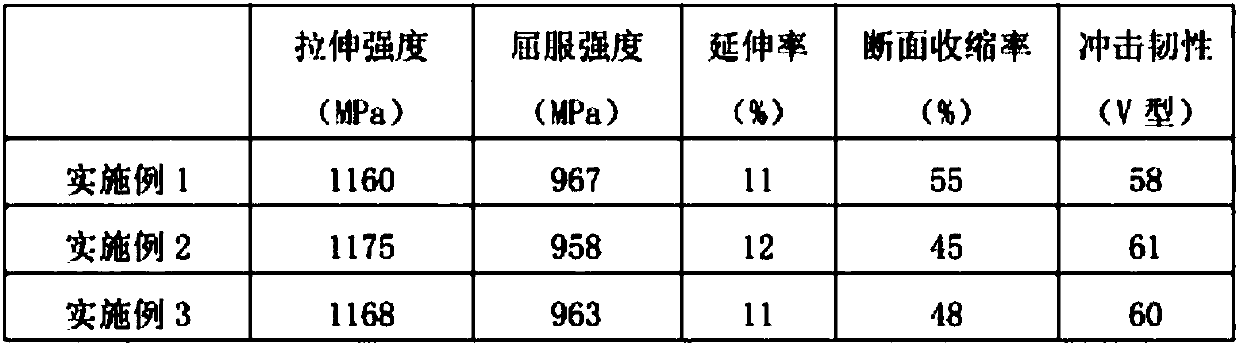

Examples

Embodiment 1

[0028] The production process of the cam sheet in this embodiment is: alloy smelting → casting steel ingot → hot rolling → diffusion annealing → blanking → blank forging → heating and punching → annealing → extrusion → machining → shot blasting treatment → quenching and tempering treatment → polishing Pill cleaning → inspection → finished product storage.

[0029] The method for producing alloy forged steel in this embodiment includes the following specific steps:

[0030] The first step is to cut the material. The steel is cut according to the size of the cam piece to obtain a blank. The steel is made by alloy smelting, casting steel ingots, hot rolling, and diffusion annealing processes in sequence. The composition of the steel alloy and its mass percentage are: carbon 0.5%, silicon 0.2%, manganese 0.85%, chromium 0.78%, aluminum 0.04%, phosphorus 0.01%, sulfur 0.006%, and the balance is iron and inevitable impurities. The existing conventional alloy melting technology is adop...

Embodiment 2

[0041] The production process of the cam sheet in this embodiment is: alloy smelting → casting steel ingot → hot rolling → diffusion annealing → blanking → blank forging → heating and punching → annealing → extrusion → machining → shot blasting treatment → quenching and tempering treatment → polishing Pill cleaning → inspection → finished product storage.

[0042] The method for producing alloy forged steel in this embodiment includes the following specific steps:

[0043] The first step is to cut the material. The steel is cut according to the size of the cam piece to obtain a blank. The steel is made by alloy smelting, casting steel ingots, hot rolling, and diffusion annealing processes in sequence. . The composition of the steel alloy and its mass percentage are: carbon 0.49%, silicon 0.18%, manganese 0.87%, chromium 0.76%, aluminum 0.05%, phosphorus 0.008%, sulfur 0.005%, and the balance is iron and inevitable impurities. The existing conventional alloy melting technology i...

Embodiment 3

[0054] The production process of the cam sheet in this embodiment is: alloy smelting → casting steel ingot → hot rolling → diffusion annealing → blanking → blank forging → heating and punching → annealing → extrusion → machining → shot blasting treatment → quenching and tempering treatment → polishing Pill cleaning → inspection → finished product storage.

[0055] The method for producing alloy forged steel in this embodiment includes the following specific steps:

[0056] The first step is to cut the material. The steel is cut according to the size of the cam piece to obtain a blank. The steel is made by alloy smelting, casting steel ingots, hot rolling, and diffusion annealing processes in sequence. The composition of the steel alloy and its mass percentage are: carbon 0.49%, silicon 0.18%, manganese 0.87%, chromium 0.76%, aluminum 0.05%, phosphorus 0.008%, sulfur 0.005%, and the balance is iron and inevitable impurities. The existing conventional alloy melting technology is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com