A Method of Fabricating Spherical Concave Mirrors on Optical Waveguides Based on Laser Ring Etching

A spherical concave, laser etching technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of difficult to control droplet shape, high material requirements, complex process, etc., to reduce the possibility of additional drawbacks, improve vertical coupling Efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

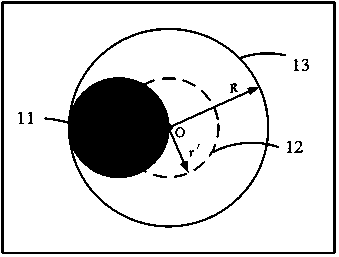

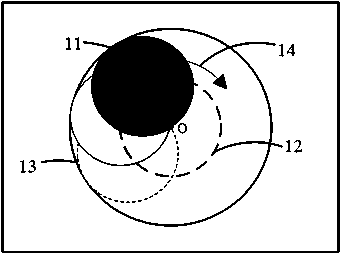

[0033] This embodiment specifically provides a processing flow for processing a spherical reflective concave surface on an optical waveguide based on an ArF excimer laser produced by OPTEC. The laser wavelength is 193 nm, and processing parameters such as laser power, moving step length, and mask pattern are optional. This embodiment uses a circular mask 11 ( Figure 2A Shown) for laser etching, the preparation process is as follows.

[0034] First, determine the processing area on the cladding surface of the optical waveguide. The diameter of the spherical concave surface to be processed must be larger than the cross-sectional width of the optical waveguide core layer so as to be able to receive all the transmitted light from the core layer. The spherical center O is symmetrically longitudinally cut on the optical waveguide core layer. On a flat surface, to ensure that the reflected beam from the spherical reflective concave surface converges directly above the concave surface to...

Embodiment 2

[0042] This embodiment uses an elliptical mask pattern 18 (such as Figure 3A Shown) The spherical reflective concave surface is processed on the optical waveguide.

[0043] The processing idea and etching process of this embodiment are basically the same as those of the first embodiment, but the shape of the processed spherical reflective concave surface is different. Let the elliptic equation be The ellipse mask is rotated and etched along a circular path at a certain angular velocity, the center of the ellipse always moves along the circular etching path 153, and one end of the minor axis of the ellipse always coincides with the center O of the reflective spherical concave surface. Take O as the center and radius as r i The etching depth of each point of the circle is the same. Select the two points A and B of the etched area as the analysis. For point A, take the center O and the radius r A The circle made passes through point A, the total depth of point A is the laser arc l...

Embodiment 3

[0047] In this embodiment, a free-curve surface mask pattern is used to etch the spherical reflective concave surface on the optical waveguide, and a strict spherical reflective concave surface can be obtained. The etching process is similar to the first embodiment. The free-form surface mask 19 pattern is obtained by inversely deducing the strict spherical reflection concave function to be obtained, such as Figure 4A Shown.

[0048] Can be combined Figure 4A Jinhe Figure 4B Determine the function expression of the free curve surface. Since the processed transverse cross-sectional figure is a semicircle with a radius of R, mark the etching depth of point A as H A , The length of the laser arc line that needs to sweep point A is l A , Under the determination of the laser power P, the etching depth of a fixed-point etching is h 0 , The distance from each point in the mask pattern to point O on the spherical reflective concave surface is r. The function expression of free curve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com