Carbon material with catalytic performance for oxygen reduction reaction and its preparation method and application

A technology of catalytic performance and carbon materials, applied in the field of carbon nanomaterials preparation and fuel cells, can solve the problems of slow fuel cells, insufficient large-scale production technology, expensive catalytic materials, etc., and achieve easy operation and excellent resistance to CO poisoning. , the effect of reducing renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

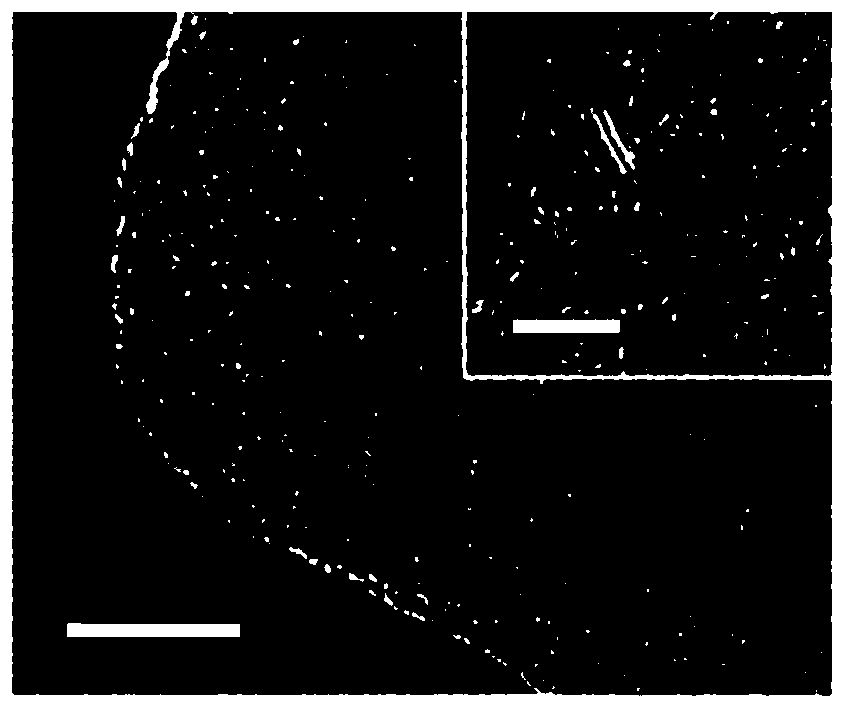

[0018] Preparation of carbon quantum dot solutions with fluorescent properties and carbon materials with excellent catalytic properties for oxygen reduction reaction: After washing and drying chrysanthemums, weigh 1 g of chrysanthemums and 30 mL of distilled water into 50 mL of polytetrafluoroethylene In the reaction kettle of gallbladder, react at 170°C for 24 h, cool to room temperature after the reaction, centrifuge the obtained brown-black product, and collect the solution part to be carbon quantum dots with fluorescent properties, and use the collected black solid to Washed repeatedly with ethanol and deionized water, mixed with 3g zinc chloride at room temperature for activation treatment, then placed in a tube furnace, reacted at 700°C for 4h, then washed repeatedly with hydrochloric acid and deionized water, and then placed Dry it in a vacuum oven at 90° C. to obtain a nitrogen-doped carbon material with catalytic activity.

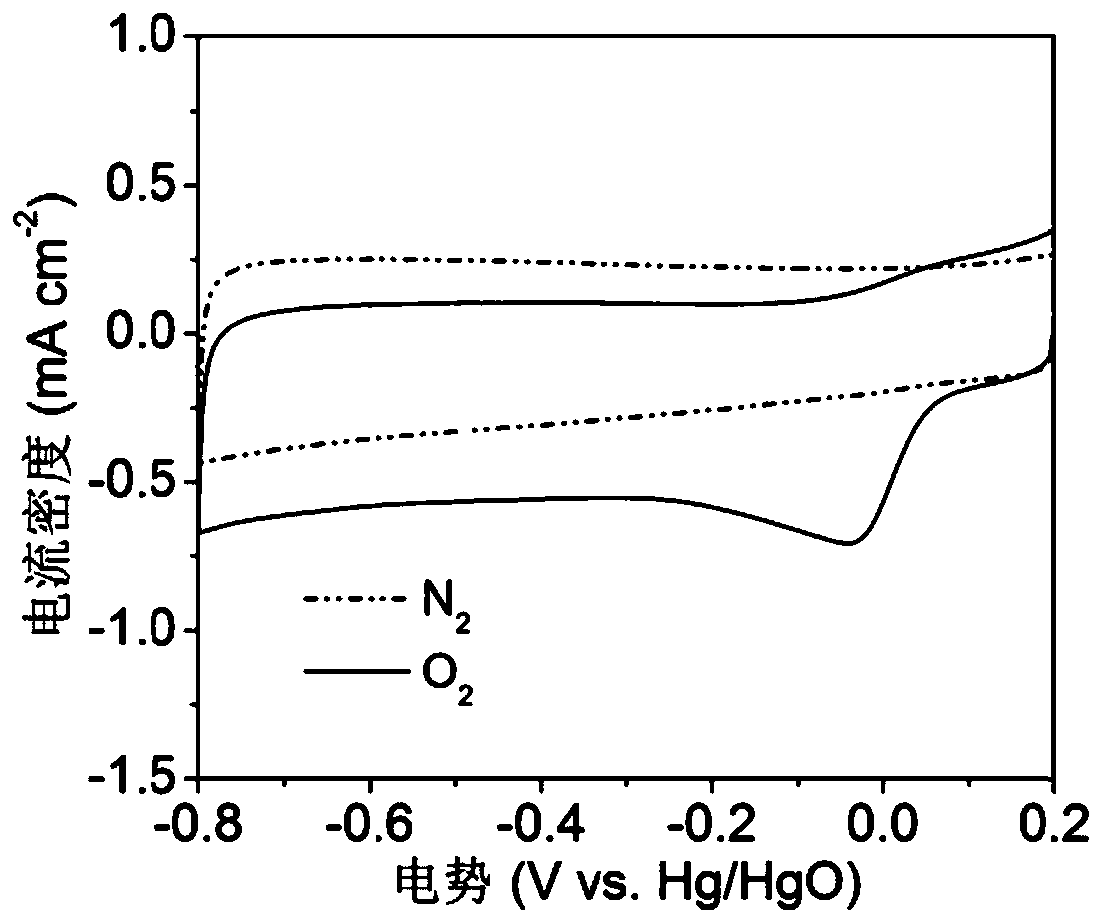

[0019] Test the application of N-doped carb...

Embodiment 2

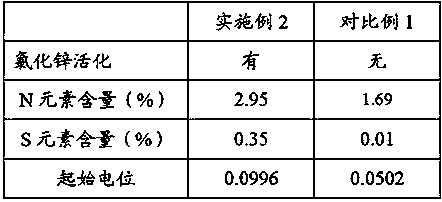

[0022] Preparation of carbon quantum dot solutions with fluorescent properties and carbon materials with excellent catalytic properties for oxygen reduction reaction: After washing and drying chrysanthemums, weigh 1 g of chrysanthemums and 30 mL of distilled water into 50 mL of polytetrafluoroethylene In the reaction kettle of the gallbladder, react at 180°C for 24 h, cool to room temperature after the reaction, centrifuge the obtained brown-black product, and collect the solution part to be carbon quantum dots with fluorescent properties. The collected black solid is used Repeated washing with ethanol and deionized water, mixed with 3g zinc chloride at room temperature for activation treatment, then placed in a tube furnace, reacted at 800°C for 4h, then repeatedly washed with hydrochloric acid and deionized water, and then placed Dry it in a vacuum oven at 90° C. to obtain a nitrogen-doped carbon material with catalytic activity.

[0023] Test the application of N-doped carb...

Embodiment 3

[0029] After washing and drying the chrysanthemum, weigh 1 g of chrysanthemum and 30 mL of distilled water into a 50 mL reaction kettle with a polytetrafluoroethylene liner, react at 180 °C for 24 h, cool to room temperature after the reaction, and prepare the obtained The brown-black product is centrifuged, and the collected solution part is carbon quantum dots with fluorescent properties. The collected black solid is washed repeatedly with ethanol and deionized water, and is mixed with 2g zinc chloride at room temperature for activation treatment, and then placed in In a tube furnace, it was reacted at 900 °C for 4 h, then washed repeatedly with hydrochloric acid and deionized water, and then dried in a vacuum oven at 90 °C to obtain a catalytically active nitrogen-doped carbon material.

[0030] Test the application of N-doped carbon materials as catalysts in oxygen reduction reaction: uniformly disperse the prepared nitrogen-doped carbon materials into the mixed solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com