Terminal-equipped electrical wire

A wire and terminal technology, used in circuits, conductive materials, conductive materials, etc., can solve the problems of low work efficiency, high yield strength, and can not withstand, and achieve the effect of improving work efficiency, high yield strength, and not easy to enter water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

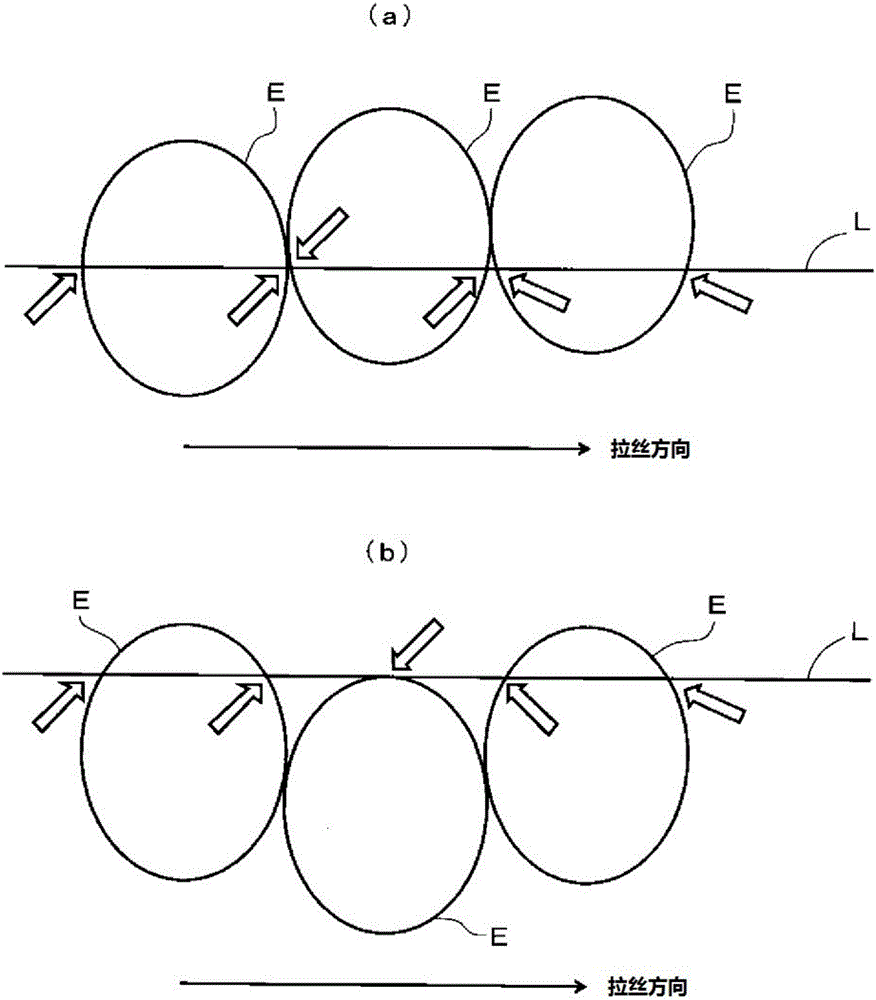

[0117] Make Mg, Si, Fe, and Al and selectively added Cu, Zr, Ti, and B the contents (mass %) shown in Table 1, using the Propez type continuous casting and rolling machine, the casting mold after water cooling Continuously cast and rolled to make approx. of bars. The casting cooling rate at this time is 1°C / sec to 20°C / sec. Next, the first wire drawing was performed so that the processing ratio shown in Table 2 could be obtained. Next, intermediate heat treatment is performed on the workpiece subjected to the first wire drawing, and then the second wire drawing is performed at the same processing rate as the first wire drawing until the wire diameter reaches Next, solution heat treatment (first heat treatment) was implemented under the conditions shown in Table 3. In addition, in the solution heat treatment, a batch type heat treatment was adopted, and a thermocouple was wound around the wire rod to measure the temperature of the wire rod. In the continuous energization ...

Embodiment 2

[0119] Except that Mg, Si, Fe and Al and selectively added Cu, Mn, Cr, Zr, Au, Ag, Hf, V, Ni, Sc, Co, Ti and B are formulated into the contents (mass %) shown in Table 4 Except, casting and rolling were carried out in the same manner as in Example 1, and approximately of bars. Next, the first wire drawing was performed so that the processing ratio shown in Table 5 could be obtained. Next, intermediate heat treatment is performed on the workpiece subjected to the first wire drawing, and then the second wire drawing is performed at the same processing rate as the first wire drawing until the wire diameter reaches Next, solution heat treatment (first heat treatment) was implemented under the conditions shown in Table 6. Then, after the solution heat treatment, aging heat treatment (second heat treatment) was performed under the conditions shown in Table 6 to manufacture aluminum alloy wires.

[0120] Each characteristic was measured by the method shown below about the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com