Mycotoxin adsorbent and preparation method thereof

A technology of mycotoxin adsorption and additives, which is applied in the direction of additional food elements, food science, animal feed, etc., can solve the problems of large deviations in production conditions and the safety of bacterial strains to be verified, and achieve low cost, improved resistance, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

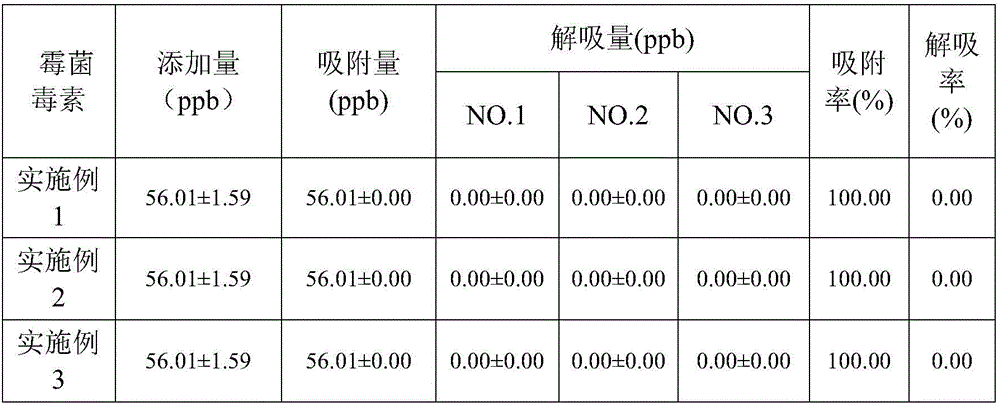

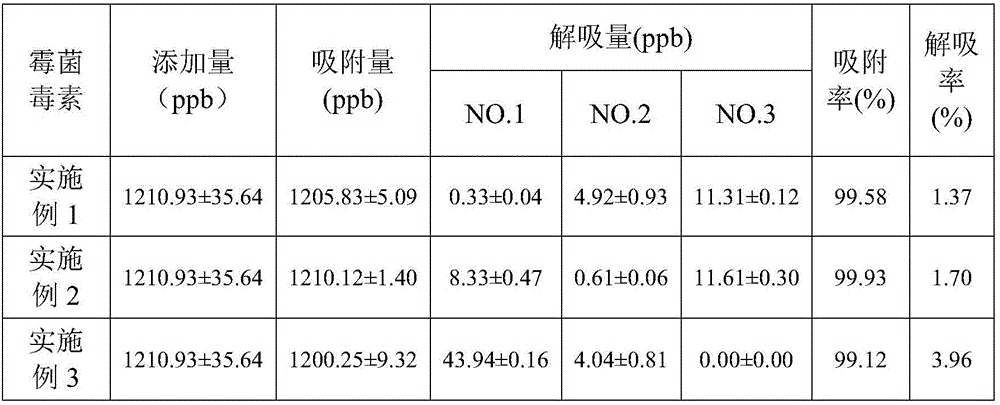

Examples

Embodiment 1

[0027] A mycotoxin adsorbent comprises the following components in parts by weight: 30 parts of sodium montmorillonite, 5 parts of medicinal activated carbon, 40 parts of cell wall of Saccharomyces cerevisiae and 37 parts of licorice.

[0028] The mycotoxin adsorbent is prepared by the following preparation method:

[0029] 1) Glycyrrhizae is pulverized into fine powder through an ultrafine pulverizer, and sieved through a 200-mesh sieve to obtain licorice powder;

[0030] 2) Weigh sodium-based montmorillonite, medicinal activated carbon, Saccharomyces cerevisiae cell wall, and licorice powder in proportion, and add them to a single-shaft paddle mixer at an ambient temperature of 20-25°C and a humidity of 60%-70% Mix for 5 minutes under certain conditions to obtain the mycotoxin adsorbent.

Embodiment 2

[0032] A mycotoxin adsorbent comprises the following components in parts by weight: 40 parts of sodium montmorillonite, 3 parts of medicinal activated carbon, 20 parts of cell wall of Saccharomyces cerevisiae and 37 parts of licorice.

[0033] The mycotoxin adsorbent is prepared by the following preparation method:

[0034] 1) Glycyrrhizae is pulverized into fine powder through an ultrafine pulverizer, and sieved through a 200-mesh sieve to obtain licorice powder;

[0035] 2) Weigh sodium-based montmorillonite, medicinal activated carbon, Saccharomyces cerevisiae cell wall, and licorice powder in proportion, and add them to a single-shaft paddle mixer at an ambient temperature of 20-25°C and a humidity of 60%-70% Mix for 5 minutes under certain conditions to obtain the mycotoxin adsorbent.

Embodiment 3

[0037] A mycotoxin adsorbent comprises the following components in parts by weight: 50 parts of sodium montmorillonite, 1 part of medicinal activated carbon, 30 parts of cell wall of Saccharomyces cerevisiae, and 19 parts of licorice.

[0038] The mycotoxin adsorbent is prepared by the following preparation method:

[0039] 1) Glycyrrhizae is pulverized into fine powder through an ultrafine pulverizer, and sieved through a 200-mesh sieve to obtain licorice powder;

[0040] 2) Weigh sodium-based montmorillonite, medicinal activated carbon, Saccharomyces cerevisiae cell wall, and licorice powder in proportion, and add them to a single-shaft paddle mixer at an ambient temperature of 20-25°C and a humidity of 60%-70% Mix for 5 minutes under certain conditions to obtain the mycotoxin adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com