Diacerein solid dispersion preparation and preparation method thereof

A technology of solid dispersion and diacerein, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pill delivery, which can solve problems affecting intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Diacerein solid dispersion tablet

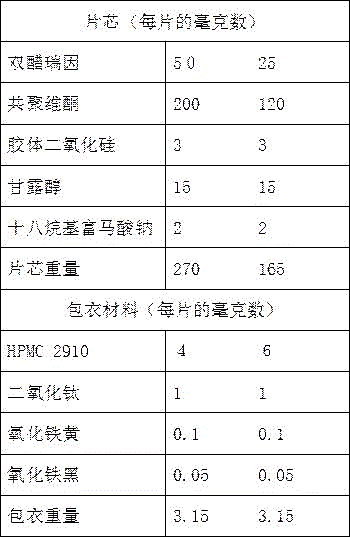

[0047] prescription:

[0048] components parts by weight Diacerein 50 Povidone K30 100 Microcrystalline Cellulose 102 50 Croscarmellose Sodium 20 Sodium dodecyl sulfate 10 silica 2 Sheet weight 232

[0049] Preparation process: solvent evaporation method

[0050]Dissolve the prescribed amount of diacerein and povidone K30 in a solvent of acetone:methanol (1:3), volatilize under reduced pressure in a water bath at 60°C, vacuum degree 0.07-0.08MPa, and recover organic matter under reduced pressure. After the solvent becomes viscous, continue vacuum drying under reduced pressure for 1 hour, transfer to a vacuum drying oven, dry at 40°C for 48 hours, and pass through an 80-mesh sieve to pulverize to obtain a solid dispersion.

[0051] The prepared solid dispersion was added into the prescribed amount of microcrystalline cellulose pH102, croscarmellose sodium, sodium ...

Embodiment 2

[0052] Embodiment 2: Diacerein solid dispersion tablet

[0053] prescription:

[0054] components parts by weight Diacerein 100 Povidone K30 200 Microcrystalline Cellulose 102 50 Croscarmellose Sodium 20 Sodium dodecyl sulfate 10 talcum powder 2 Sheet weight 387

[0055] Preparation process: solvent evaporation method

[0056] Take the prescribed amount of diacerein and povidone K30, dissolve in the solvent of methanol:dichloromethane (4:1), put in a water bath at 60°C, vacuum degree 0.07-0.08MPa, recover the organic solvent under reduced pressure, wait for After becoming viscous, continue vacuum drying under reduced pressure for 1 hour, transfer to a vacuum drying oven, dry at 40°C for 48 hours, and pass through an 80-mesh sieve to pulverize to obtain a solid dispersion.

[0057] The prepared solid dispersion is added into the prescribed amount of microcrystalline cellulose pH102, crospovidone, sodium lauryl sulfate, ...

Embodiment 3

[0058] Embodiment 3: Diacerein solid dispersion tablet

[0059] prescription:

[0060] components parts by weight Diacerein 25 Povidone K30 100 Microcrystalline Cellulose 102 50 Croscarmellose Sodium 20 Sodium dodecyl sulfate 10 silica 2 Sheet weight 207

[0061] Preparation process: solvent evaporation method

[0062] Dissolve the prescribed amount of diacerein and povidone K30 in a solvent of acetone:dichloromethane (3:1), in a water bath at 55°C, with a vacuum of 0.07-0.08MPa, and recover the organic solvent under reduced pressure. After becoming viscous, continue vacuum drying under reduced pressure for 3 hours, transfer to a vacuum drying oven, dry at 60°C for 48 hours, and pass through an 80-mesh sieve to pulverize to obtain a solid dispersion.

[0063] The prepared solid dispersion is added to the prescribed amount of pregelatinized starch, low-substituted hydroxypropyl cellulose, sodium lauryl sulfate, and sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com