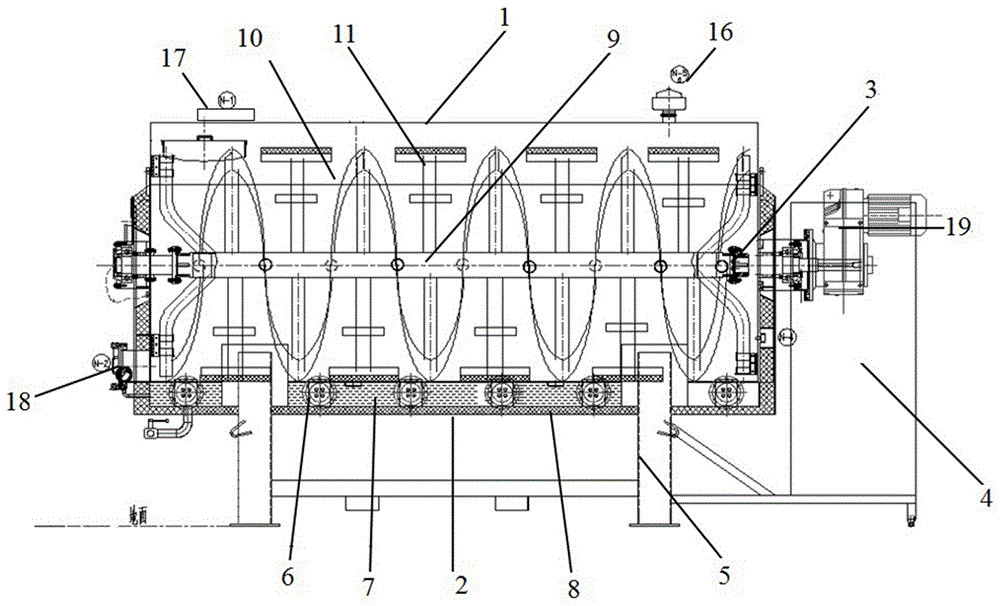

Substrate fast sterilization and disinfection device and application thereof

A sterilizing device and substrate technology, applied in the direction of disinfection, application, water supply devices, etc., can solve the problems of small amount of single disinfection, incomplete disinfection, cumbersome operation, etc., to promote the process of mineralization and humification, compact structure , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

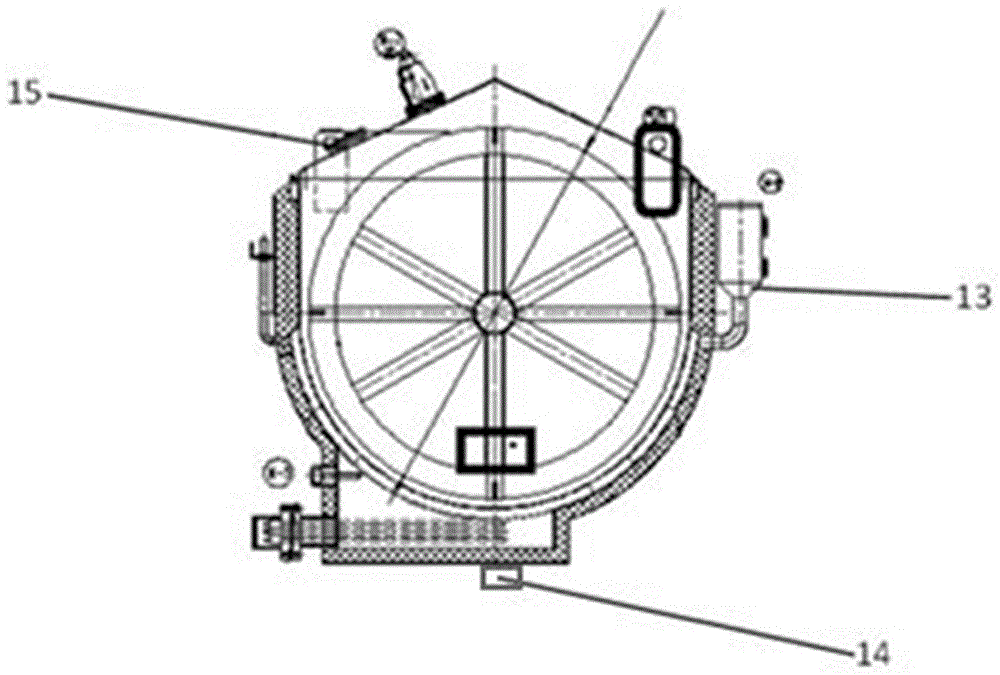

Method used

Image

Examples

Embodiment 1

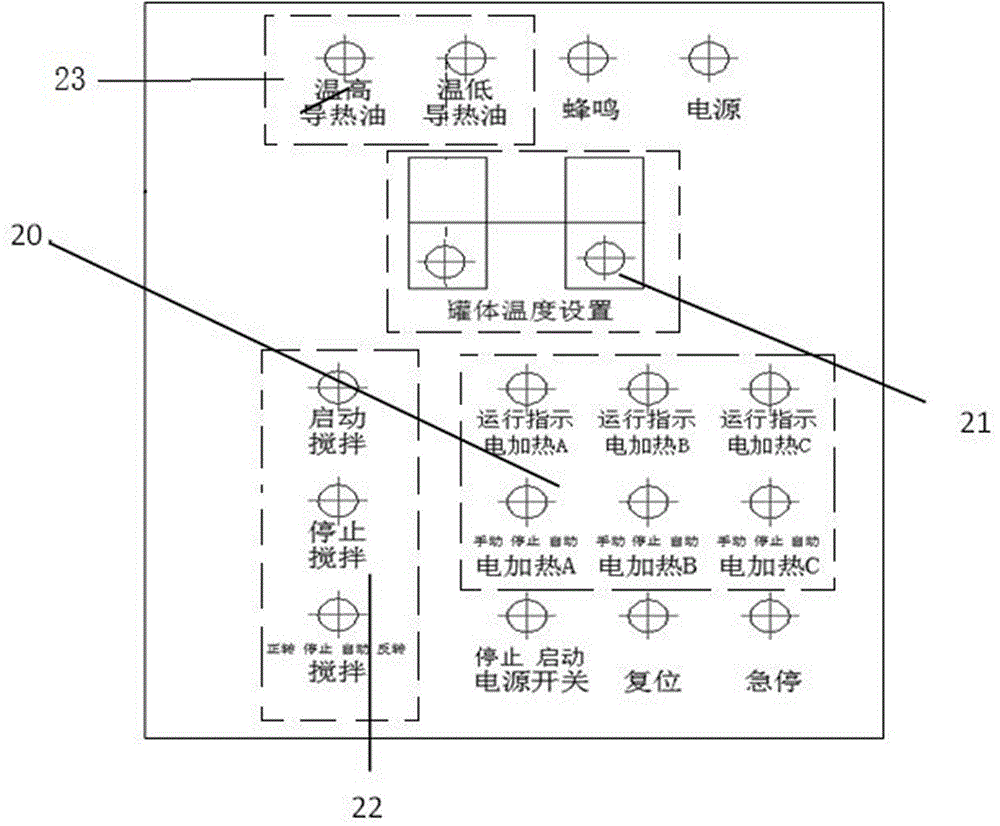

[0045] Under the condition of low temperature in winter (outdoor temperature is lower than 10°C), the substrate for planting a crop of watermelons should be disinfected.

[0046] (1) Set the automatic program: set the target temperature of the heat transfer oil to 120°C, the target temperature inside the tank to 75°C, and the switching time between modes for the driving direction of the drive motor 19 to be 20 seconds. The system automatically starts the electric heater switch circuit 20. Since the temperature inside the horizontal tank is low, three sets of electric heaters 6 are started at the same time. At this time, the maximum power is 100kw. After about 15 minutes, the temperature of the heat transfer oil reaches or approaches the target temperature in the tank. , the warm-up ends. Turn off both sets of heating elements.

[0047] (2) Feeding: Use the crawler conveyor mechanism 12 to put 2.5 cubic meters of watermelon-planted substrate into the horizontal tank 1, and the...

Embodiment 2

[0053] Under the condition of low temperature in winter (outdoor temperature below 10°C), disinfect tomato stalks

[0054] The technical solution of embodiment 2 is basically the same as that of embodiment 1, the only difference is that the feed amount of tomato stalks can reach 3 cubic meters, and the disinfection time in the horizontal tank 1 can be shortened to 1 hour.

[0055] The experimental results shown in Fig. Image 6 ,: The number of cultivable fungi (Red Bengal medium) in tomato stalks before feeding (A in the figure) was 9.06×10 3 CFU / g, the number of cultivable fungi after disinfection (B in the figure) was not found in Bengal red medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com