Shell-based air purifying material and preparation method thereof

A technology of air purification materials and shells, applied in the field of green ecological environment building materials, to achieve the effects of excellent self-humidity adjustment, broad decorative expressiveness, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: A shell-based air purification material-powder

[0054] The raw material formula is (substance measurement unit is weight part):

[0055] ① Shell powder 100 parts

[0056] ② 58 parts of calcium chloride dihydrate

[0057] ③ 30 parts of ammonia water with a mass concentration of 20%

[0058] ④ 180 parts of hydrogen peroxide with a mass concentration of 30%

[0059] ⑤ 60 parts of 120-220 mesh natural hemihydrate gypsum

[0060] ⑥165.33 parts of water

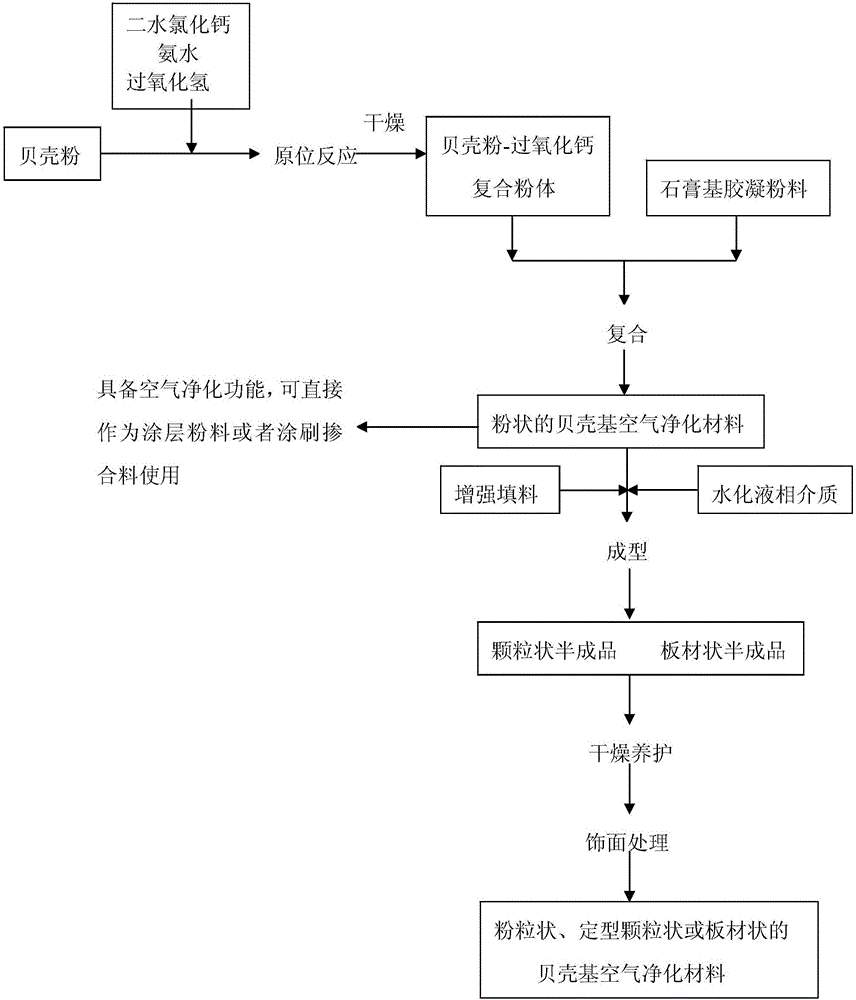

[0061] It is prepared by the following method, the flow chart is as follows figure 1 Shown:

[0062] (1) pretreatment: add 30 parts of water in 30 parts of ammonia water and be prepared into aqueous ammonia solution; Add 135.33 parts of water in 58 parts of calcium chloride dihydrates and be prepared into the calcium chloride dihydrate aqueous solution that mass concentration is 30%;

[0063] (2) In-situ reaction: add the obtained calcium chloride dihydrate aqueous solution to the stirred tank, then immers...

Embodiment 2

[0065] Example 2: A shell-based air purification material-particles

[0066] The raw material formula is (substance measurement unit is weight part):

[0067] ① Shell powder 100 parts

[0068] ② 60 parts of calcium chloride dihydrate

[0069] ③ 35 parts of ammonia water with a mass concentration of 20%

[0070] ④ 200 parts of hydrogen peroxide with a mass concentration of 30%

[0071] ⑤ 20 parts of 120-220 mesh natural hemihydrate gypsum

[0072] ⑥ 95 parts of water

[0073] ⑦Reinforcing filler 1.0 parts (mineral fiber with a length of 0.7mm, the mineral fiber is basalt fiber)

[0074] ⑧ 28 parts of hydration liquid phase medium (combined and stirred by water, polymer emulsion, waterproofing agent and defoamer according to the mass ratio of 100:0.8:0.1:0.5 to form a uniform compound solution, wherein the polymer emulsion has a solid content of 50% seaweed biogel, water repellent is potassium methyl siliconate, defoamer is tributyl phosphate)

[0075] It is prepared by t...

Embodiment 3

[0082] Example 3: A shell-based air purification material-plate shape

[0083] The raw material formula is (substance measurement unit is weight part):

[0084] ① Shell powder 100 parts

[0085] ② 80 parts of calcium chloride dihydrate

[0086] ③ 40 parts of ammonia water with a mass concentration of 20%

[0087] ④ 250 parts of hydrogen peroxide with a mass concentration of 30%

[0088] ⑤ 80 parts of 120-220 mesh gypsum-based gelling powder (76 parts of desulfurized hemihydrate gypsum, 4 parts of white cement)

[0089] ⑥105.45 parts of water

[0090] ⑦ 1.5 parts of reinforcing filler (glass fiber with a length of 18-22mm)

[0091] ⑧ 58 parts of hydration liquid phase medium (by water, polymer emulsion, waterproofing agent, antifoaming agent according to its mass ratio is 100: 1.5: 0.5: 2.0 composite stirring to form a uniform compound solution, wherein the polymer emulsion is a solid content of 50% silicone acrylic emulsion, water repellent is potassium methyl siliconate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com