Reaction device for strengthened heat transfer and continuous production method with strong exothermic reaction

A reaction device, a technology for enhancing heat transfer, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical industry, etc., can solve problems such as poor heat transfer effect, reduce corrosion and improve Safety and productivity, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

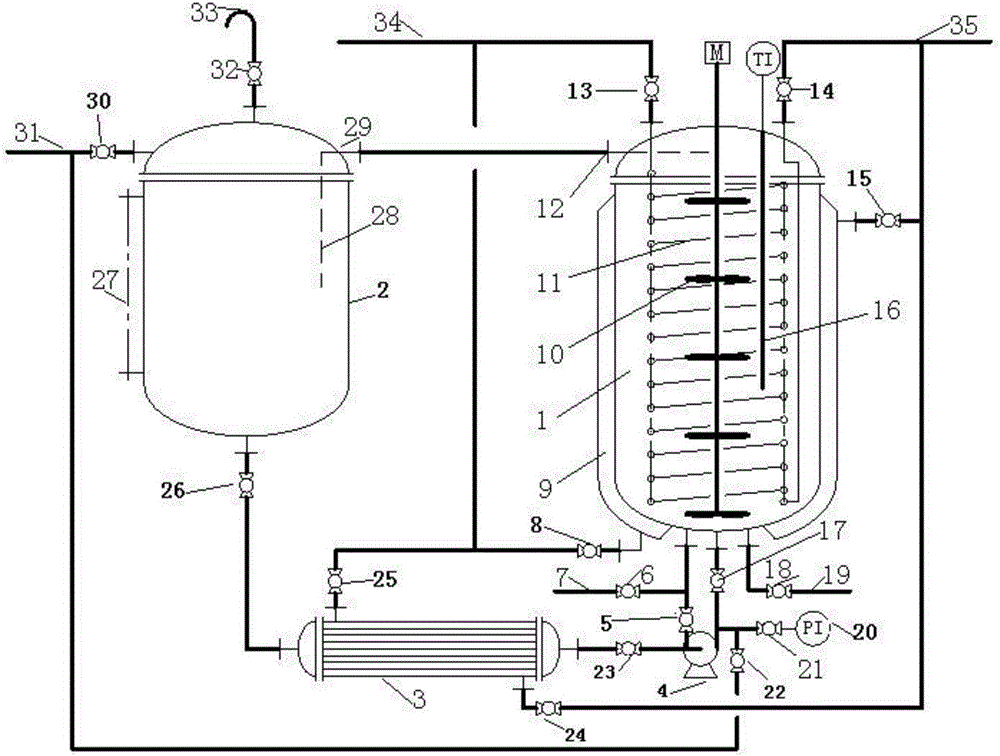

[0031] figure 1 A reaction device for enhancing heat transfer is provided, which includes a reaction kettle 1 , a crude product tank 2 , a cooler 3 and a circulation pump 4 .

[0032] Reactor 1 is a mechanical stirring container with an oval head and a detachable cover specified in HG / T 3109-2009, with a volume of 3000L. A material outlet 12 is provided at the top of the reactor 1, an inlet 36 for raw material A and an inlet 37 for raw material B are arranged at the bottom, and a circulation inlet 38 is provided between the two raw material inlets. The reactor 1 is provided with a jacket 9 on the outside, and a stirrer 10 , a coil 11 and a thermal resistance thermometer 16 inside. The stirrer 10 includes a stirring shaft, on which there are multiple layers of radial stirring blades. The heat exchange area of the jacket 9 is 10m2, the heat exchange area of the coil is 30m2, and the measuring range of the thermal resistance thermometer 16 is -20~100°C.

[0033] Reactor 1 ...

Embodiment 2

[0046] This embodiment provides a continuous production method of a strong exothermic reaction. Taking phosphorus trichloride and methanol to synthesize phosphite as an example, the specific operation of the method is described in detail. The device used is referred to in Example 1.

[0047] (1) Preparation: close the vent valve 32, purge valve 5 and exhaust valve 22, open the pressure gauge valve 21, the circulation valve 23 before the pump, the circulation outlet valve 26 and the crude product outlet valve 30, open the jacket inlet valve 8, clamp The sleeve outlet valve 15, the coil inlet valve 13, the coil outlet valve 14, the shell side inlet valve 25 and the shell side outlet valve 24 pass circulating water into the jacket 9, the coil tube 11 and the cooler 3;

[0048] (2) Operation: start the agitator 10, open the raw material A inlet valve 6 and the raw material B inlet valve 18, and continuously add phosphorus trichloride and methanol to the reaction kettle 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com