S/Ti<3+> dual-doped TiO2 nanotube array preparation method

A nanotube array, double-doping technology, applied in nanotechnology, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of weak response to visible light, easy recombination of photogenerated electrons and holes, and achieve high response to visible light. The effect of improving capacity, low comprehensive cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

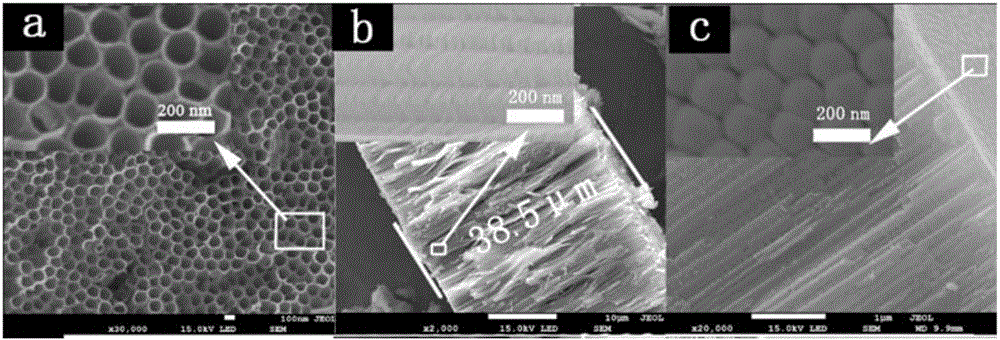

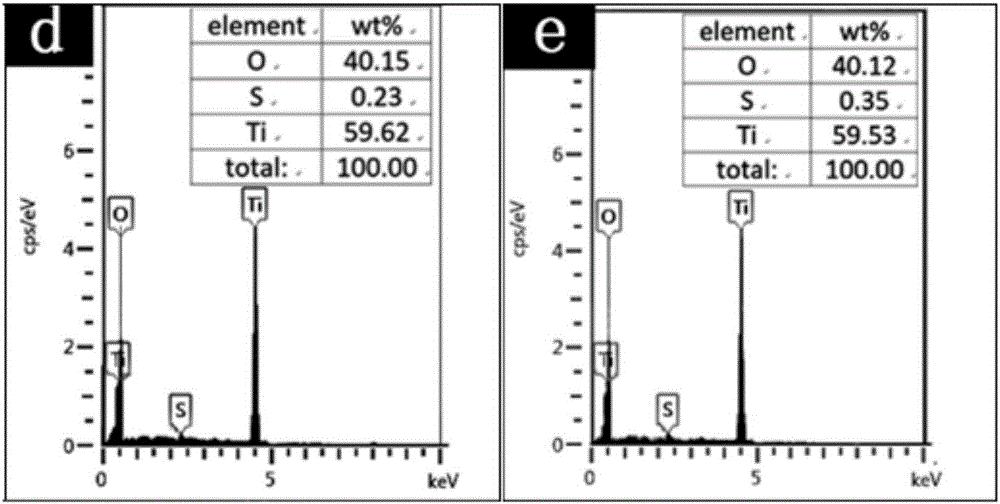

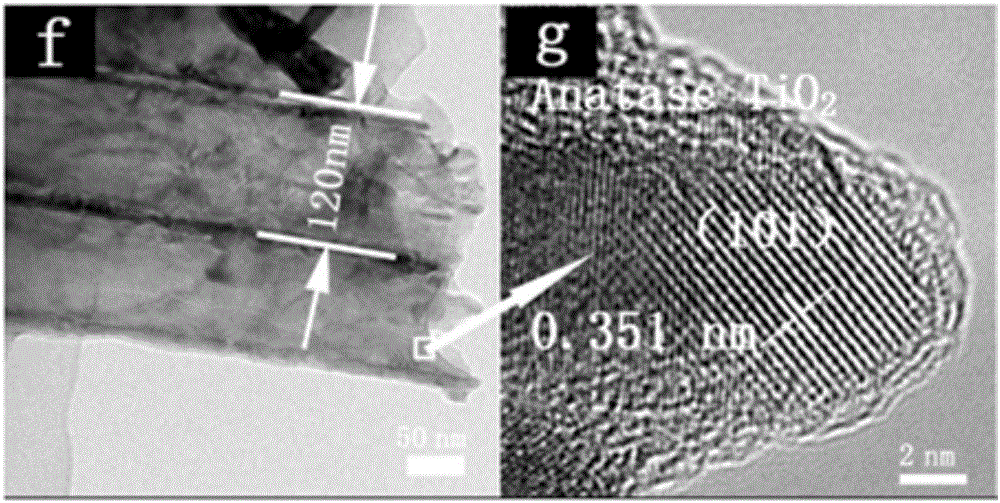

[0031] (1) Preparation of TiO 2 nanotube array

[0032] Use 600#, 800#, 1000# metallographic sandpaper of different specifications to polish the surface of the titanium sheet in turn. The size of the titanium sheet is 1x2cm 2 , using HF:HNO with a volume ratio of 1:4:5 3 :H 2 The mixed solution of O carries out chemical polishing to described titanium sheet, and after chemical polishing is finished, titanium sheet is carried out ultrasonic cleaning with deionized water, acetone, dehydrated alcohol successively, and drying standby, finishes the pretreatment to titanium sheet; Put into the NH of 0.5:0.5:99 in the mass fraction ratio (wt%) of the titanium sheet that passes 4 F, H 2 In the electrolyte composed of O and ethylene glycol, the titanium sheet was anodized at a voltage of 50V for 6h.

[0033] (2) soaking treatment

[0034] Pure TiO after anodic oxidation 2 The nanotube arrays were soaked in 30g / L thiourea solution for different periods of time. During the soaking...

Embodiment 2

[0038] (1) Preparation of TiO 2 nanotube array

[0039] Use 600#, 800#, 1000# metallographic sandpaper of different specifications to polish the surface of the titanium sheet in turn. The size of the titanium sheet is 1.5x3cm 2 , using HF:HNO with a volume ratio of 1:4:5 3 :H 2The mixed solution of O chemically polishes the titanium sheet, and then ultrasonically cleans the titanium sheet with deionized water, acetone, and absolute ethanol in sequence, and then dries for use to complete the pretreatment of the titanium sheet; put the pretreated titanium sheet into a mass NH with a part ratio (wt%) of 0.5:0.5:99 4 F, H 2 In the electrolyte composed of O and ethylene glycol, the titanium sheet was anodized at a voltage of 50V for 6h.

[0040] (2) soaking treatment

[0041] Pure TiO after anodic oxidation 2 The nanotube arrays were soaked in 60g / L thiourea solution for different periods of time. During the soaking process, ultrasonic treatment was performed for 60s every 1...

Embodiment 3

[0045] (1) Preparation of TiO 2 nanotube array

[0046] Use 600#, 800#, 1000# metallographic sandpaper of different specifications to polish the surface of the titanium sheet in turn. The size of the titanium sheet is 2x4cm 2 Use HF:HNO with a volume ratio of 1:4:5 3 :H 2 The titanium sheet is chemically polished with a mixed solution of O, and then ultrasonically cleaned with deionized water, acetone, and absolute ethanol in sequence, and dried for later use. Put the pretreated titanium sheet into NH 4 F, H 2 Composed of O and ethylene glycol, the mass fraction ratio (wt %) is 0.5:0.5:99 in an electrolyte solution with a voltage of 50V for 6h.

[0047] (2) soaking treatment

[0048] Pure TiO after anodic oxidation 2 The nanotube arrays were soaked in 90g / L thiourea solution for different periods of time. During the soaking process, they were ultrasonically treated for 30s at intervals of 1h, and cycled sequentially for a total of 12h.

[0049] (3) heat treatment

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com