Porous platinum/palladium alloy nanoparticle catalyst as well as preparation method and application thereof

A technology of nano-particles and palladium alloys, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that the performance of Pt/C catalysts cannot meet the requirements, etc. , to achieve the effect of simple preparation method, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

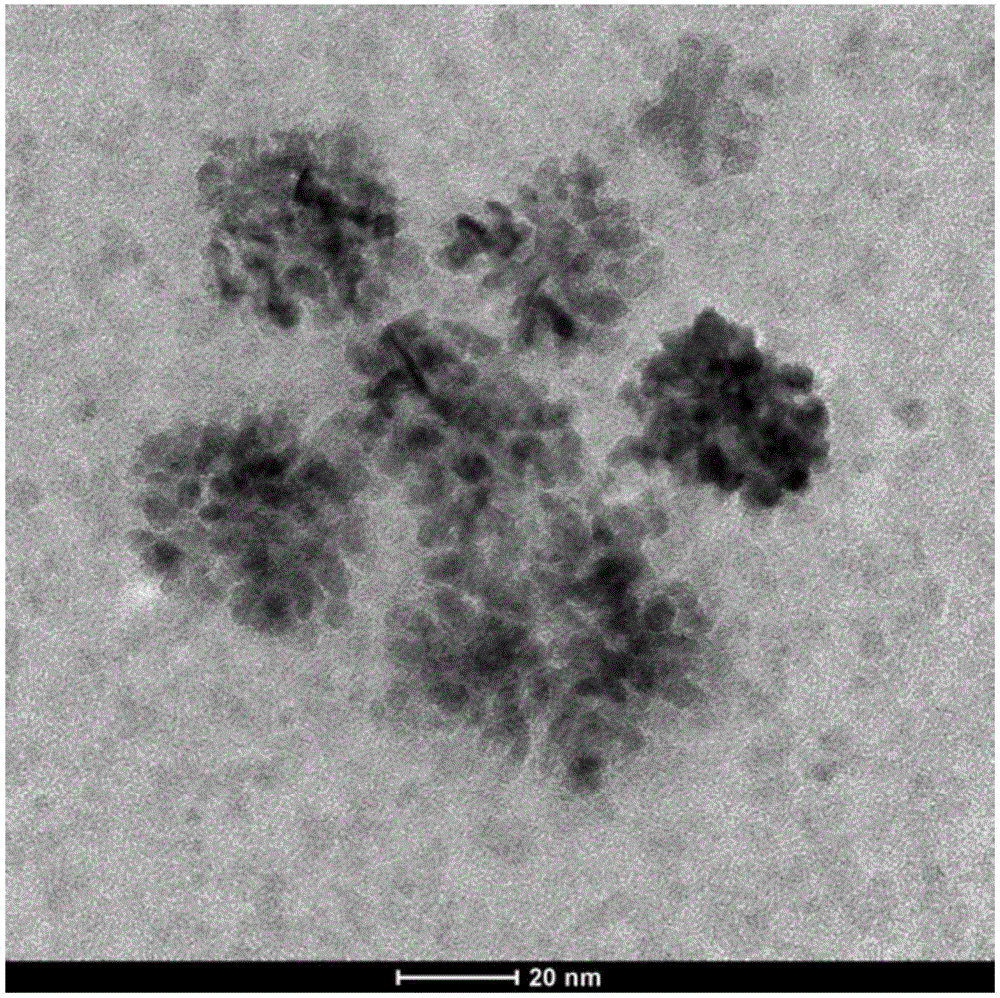

[0029] A kind of preparation method of porous platinum / palladium alloy nano particle catalyst, described preparation method comprises the following steps:

[0030] A. Add 80uL of 0.01M chloroplatinic acid aqueous solution to 9.75mL of 0.1M CTAC aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and put it in a 36°C oven for 3 hours to prepare get the seed solution;

[0031] B. Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 120 μL of 0.01M chloropalladium acid aqueous solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1M CTAC aqueous solution, and keep the temperature at 36°C Stand still in the oven for 70 hours, then centrifuge to remove the supernatant, wash the precipitate with water once and centrifuge again, and then the porous platinum / palladium alloy nanoparticle catalyst can be prepared.

[0032] The molar percentage of palladium in th...

Embodiment 2

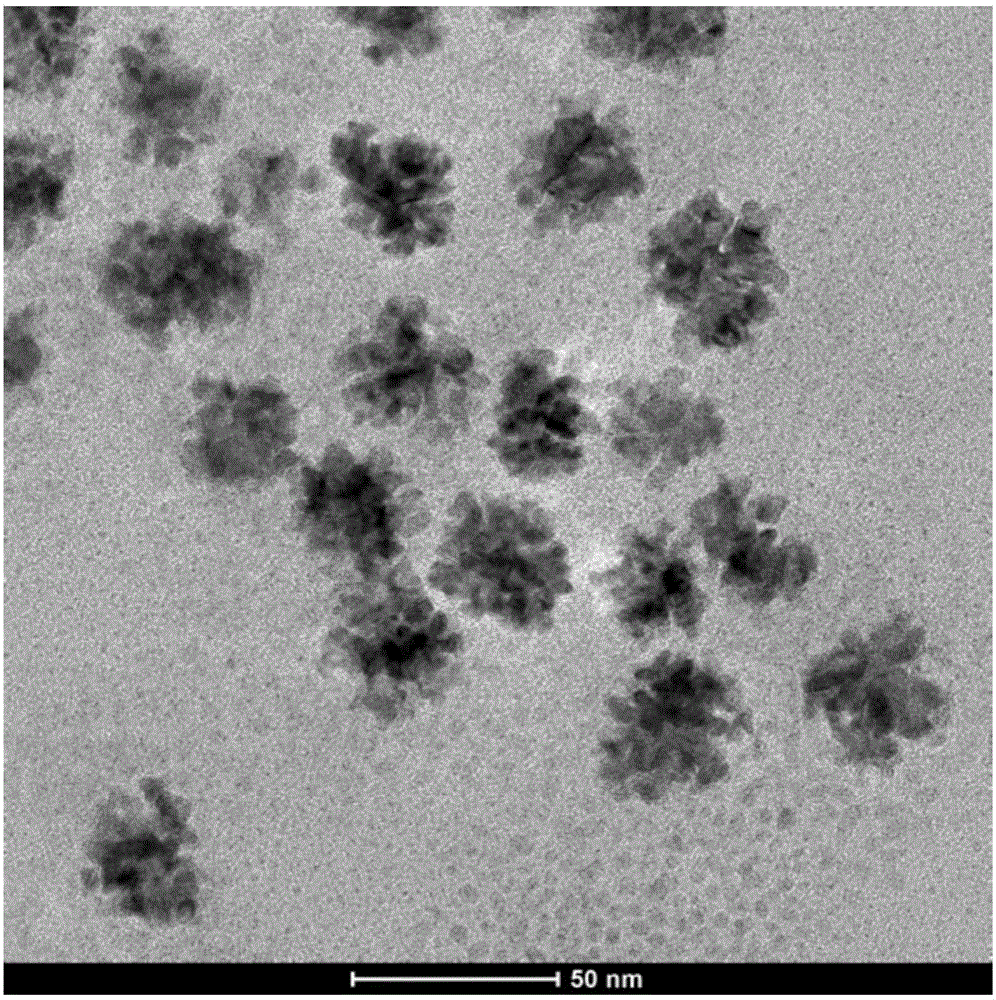

[0034] A kind of preparation method of porous platinum / palladium alloy nano particle catalyst, described preparation method comprises the following steps:

[0035]A. Add 80uL of 0.01M chloroplatinic acid aqueous solution to 9.75mL of 0.1M CTAC aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and put it in a 36°C oven for 3 hours to prepare get the seed solution;

[0036] B. Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 240 μL of 0.01M chloropalladium acid aqueous solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1M CTAC aqueous solution, and keep the temperature at 36°C Stand still in the oven for 20 hours, then centrifuge to remove the supernatant, wash the precipitate with water once, and then centrifuge to prepare a porous platinum / palladium alloy nanoparticle catalyst.

[0037] The molar percentage of palladium in the product measured...

Embodiment 3

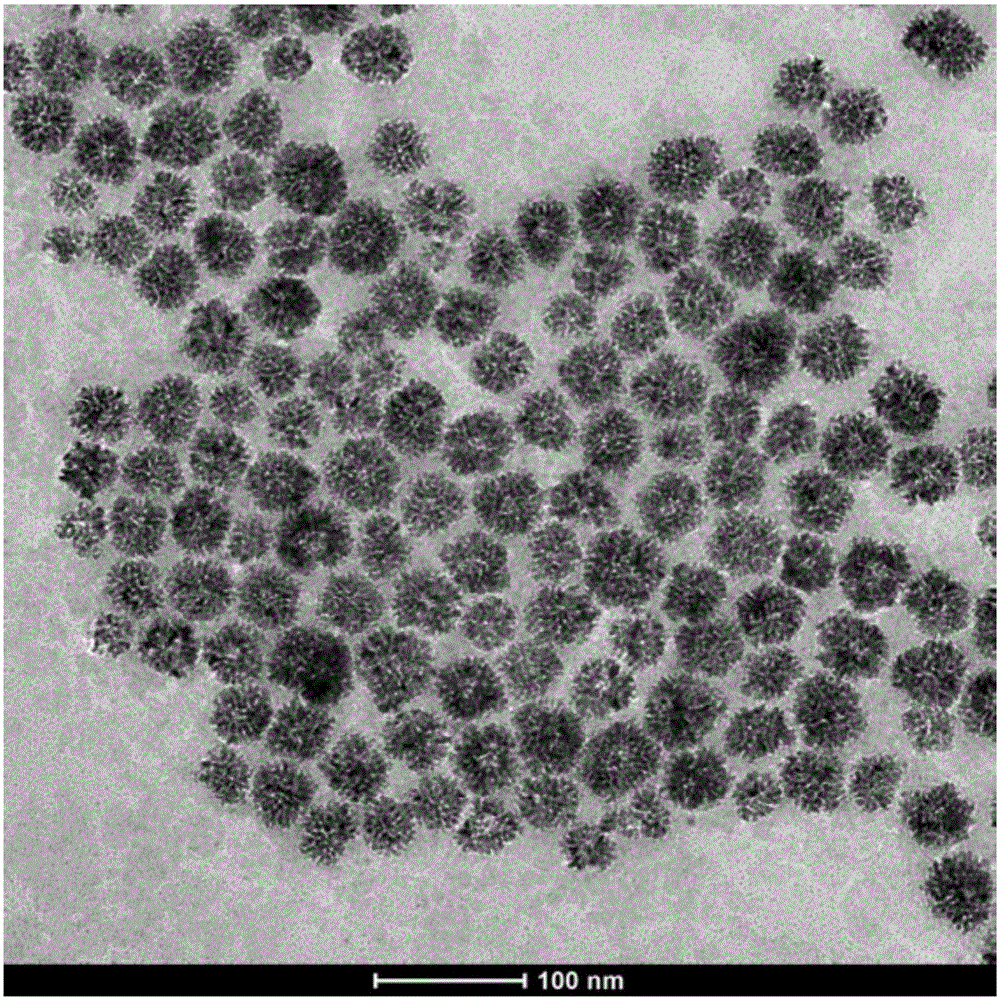

[0039] A kind of preparation method of porous platinum / palladium alloy nano particle catalyst, described preparation method comprises the following steps:

[0040] A. Add 80uL of 0.01M chloroplatinic acid aqueous solution to 9.75mL of 0.1M CTAC aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and put it in a 36°C oven for 3 hours to prepare get the seed solution;

[0041] B. Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 240 μL of 0.01M chloropalladium acid aqueous solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1M CTAC aqueous solution, and keep the temperature at 36°C Stand still in the oven for 70 hours, then centrifuge to remove the supernatant, wash the precipitate with water once and centrifuge again, and then the porous platinum / palladium alloy nanoparticle catalyst can be prepared.

[0042] The molar percentage of palladium in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com